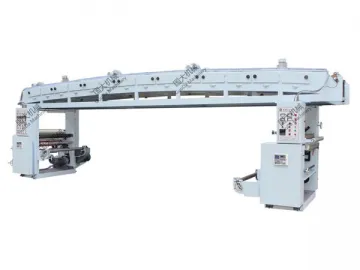

Printing Material Laminating Machine

This printing material laminating machine is able to laminate about 80m to 90m of materials within every minute and it is applied to BOPP, PET, CPP, PVC aluminum plated film, aluminum foil and other combined films of the same nature, as well as paper, etc.

Main Configurations

1. Main transmission structure

The main transmission device of the machine is controlled by AC variable frequency vector. The glue spreading roller and heating roller keep synchronized control with oscillating arm on the tightness of the film of drying tunnel.

2. Unwinding device

The photoelectric correcting unwinding equipment is used for the first unwinding material with the automatic tension controller.

3. Glue spreading device

The glue spreading amount is subject to the anilox roller that is controlled by independent motor. Even if the main motor stops, the anilox roller is capable of rotating still at adjustable speed.

4. Drying oven

With the internal recycling device, the drying oven works at three sections of temperature, which is controlled separately in different sections.

5. Laminating heating roller and compression roller

Laminating heating roller of the printing material laminating machine performs with conduction oil so that it heats evenly and saves much electricity. The compression roller can be controlled by double cylinders and its pressure is adjusted at random.

6. Rewinding device

The torque motor is used for rewinding the materials.

Technical Parameter

| Model | GF-800B1 | GF-1000B1 |

| Laminating layer | 2 | 2 |

| Laminating width | 800mm | 1000mm |

| Diameter of unwinding or rewinding roll | 650mm | 650mm |

| Laminating speed | 80-90m/min | 80-90m/min |

| Temperature of oven | 80ºC | 80ºC |

| Temperature of laminating roller | 70ºC-90ºC | 70ºC -90ºC |

| Total power | 48kw | 60kw |

| Weight of machine | 5000kg | 6000kg |

| Overall dimension | 8300×2000×2750mm | 8300×2200×2750mm |

Related Names

BOPP Film Dry Laminating Machine | PET Film Lamination Machine | China CPP Film Laminator

Links:https://www.globefindpro.com/products/83767.html

-

Lithium Ion Battery Packs

Lithium Ion Battery Packs

-

Electric Bike Battery Packs

Electric Bike Battery Packs

-

Mobile Phone Batteries

Mobile Phone Batteries

-

Stainless Steel Perforated Pipe

Stainless Steel Perforated Pipe

-

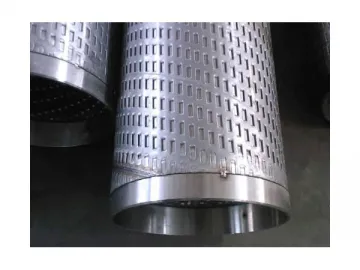

Bridge Slotted Screen

Bridge Slotted Screen

-

Reinforced Bridge Slotted Screen

Reinforced Bridge Slotted Screen

-

LiFePO4 Battery Packs

LiFePO4 Battery Packs

-

Lithium Polymer Battery Packs

Lithium Polymer Battery Packs

-

Stainless Steel Wedge Wire Screen

Stainless Steel Wedge Wire Screen

-

Portable Solar Chargers

Portable Solar Chargers

-

Meat Slicer

Meat Slicer

-

Oil Casing Coupling

Oil Casing Coupling