Steel Grating

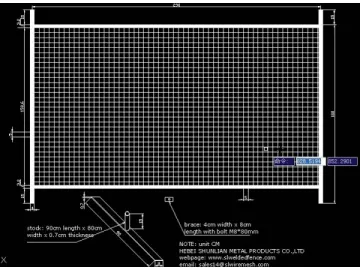

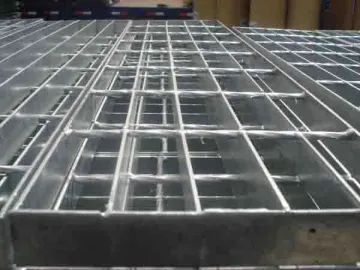

The steel grating is a joined grid. It is made by joining regularly-spaced, longitudinal flat bars to the cross bars at the required spacing, via a process known as electric resistance welding at high voltage. After welding, the grate is then sent for cutting, notching, boring, and edge coating to yield customer desired product.

Generally speaking, we provide three different flat bar spacing parameters: 300mm, 40mm, and 60mm.

Specifications

1. Flat Bar: The flat bar is made of Q235A or stainless steel. It comes in three types: flat surface, anti-skid teeth, and I-shaped cross section. Common flat bar sizes are: 20×5, 25×5, 25×3, 32×5, 32×5, 40×5, 40×3, 50×5, 65×5, 75×6, 100×8, and 100×10.

2. Cross Bar: The cross bar is made of Q235A or 304 stainless steel round bar, twisted square bar, and hexagonal bar. The twisted square bar is made of coiled steel drawn through a square die prior to twisting it. Common cross bar specifications include: 5×5, 6×6, and 8×8.

Features

1. Its sturdy grid features a welded structure, which lends the grate strength and load bearing capacity.

2. The lightweight structure makes for easy lifting and installation.

3. For durability and beauty, the steel grating has been subjected to hot-dip galvanization which produces a thick layer of zinc to protect the grate surface from corrosion.

4. It is a widely-used product, popular also due to its good ventilation, heat dissipation, explosion proof, and anti-skid characteristics.

5. Additionally, the grate offers a comfortable level of natural lighting as well as keeps out dirt from entering the other side of the grate.

Applications

1. Typical applications are in the petrochemical industry, power plant, water treatment plant, civil engineering project, and environmental protection project.

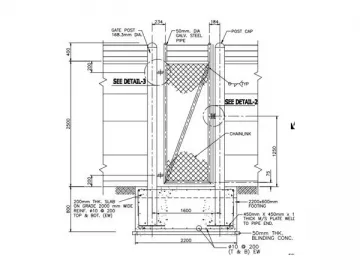

2. The product is also well-suited for use in the platform, sidewalk, pier, manhole cover, drainage cover, ladder, guard fence, and enclosure fencing.

Related Names

Anti-skid Steel Mesh | Welded Wire Mesh | Steel Well Cover

Links:https://www.globefindpro.com/products/83811.html