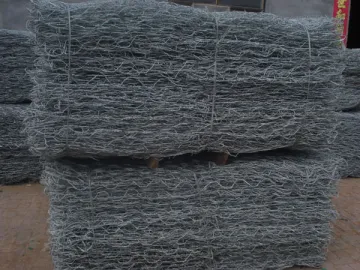

Galvanized Steel Wire

Process

The galvanized steel wire is fabricated with the Q195 6.5mm diameter low carbon steel that has subjected to a series of processes, including drawing, pickling, annealing, galvanizing, and cooling.

Features

The said processes give the wire good toughness, elasticity, and other desirable characteristics. In particular, the galvanization process allows maximum 300g zinc to be applied to 1m2 of the steel wire. The thick zinc coating protects the wire from corrosion.

Applications

This series of wire product is extensively used in the building, handicraft, woven wire mesh, guard fence for highway, product package, and various commercial products.

Process Analysis

Galvanized steel wire has undergone one the two surface treatments: either zinc electroplating or hot-dip galvanizing. Based on this, we can categorize the wire into two types: hot-galvanized and electro-galvanized.

Hot-dip galvanization is the process of dipping steel wire into molten zinc to rapidly produce a corrosion-resistant coating. The protective zinc coating provided by hot-dip galvanizing s is usually uneven across the wire surface. Steel wire that has undergone this surface treatment usually obtains dark color on its surface. The treating process also requires large amount of zinc. Nonetheless, this process allows a wide range of thicknesses of zinc layer to be applied to the wire surface, varying from 45μm to 300μm. Moreover, the massive zinc can a form an anti-corrosive layer to protect the underlying metal. The coating can be kept on the wire surface for several decades in outdoor environment.

Electro-galvanizing or cold galvanizing is a rather slow process by which free zinc ions form a thin layer of coating on the wire. The resulting zinc layer is uniform and even across the whole wire surface. However, the coating obtained via this method is usually very thin with a narrow range from 3μm to 15μm. Within a couple of months, its shiny appearance would fade away and rust began to grow.

Additionally, it is worth noting that electroplating is less costly than hot-dip galvanization.

Application

Due to its thick coating, hot-dip galvanized steel wire can deal with harsh working conditions. Therefore, it is well-suited for use on the chemical equipment and metal structure or in the petroleum processing, ocean exploration, power transmission, and ship building industries. Recent years, this wire product has also been used in farm chemical sprinkle irrigation, greenhouse, and water and gas transmission system. Other typical usages include the electrical conduit, scaffold, bridges, and highway guard fence.

Categories

1. Baling wire for construction application mainly adopts cold galvanized wire.

2. Wire craft is usually made of one single thread of craft wire which has a shiny, evenly zinc-coated surface and no broken end.

3. Bulk wire which is wound in a coil has a weight range from 100kg to 1000kg. It is mainly used in industry, agriculture, and livestock farm industry.

Specifications

| Wire Gauge Size | Standard Wire Gauge(mm) | Birmingham Wire Gauge (mm) | Metric(mm) |

| 8 | 4.06 | 4.19 | 4.00 |

| 9 | 3.66 | 3.76 | - |

| 10 | 3.25 | 3.40 | 3.50 |

| 11 | 2.95 | 3.05 | 3.00 |

| 12 | 2.64 | 2.77 | 2.80 |

| 13 | 2.34 | 2.41 | 2.50 |

| 14 | 2.03 | 2.11 | - |

| 15 | 1.83 | 1.83 | 1.80 |

| 16 | 1.63 | 1.65 | 1.65 |

| 17 | 1.42 | 1.47 | 1.40 |

| 18 | 1.22 | 1.25 | 1.20 |

| 19 | 1.02 | 1.07 | 1.00 |

| 20 | 0.91 | 0.89 | 0.90 |

| 21 | 0.81 | 0.813 | 0.80 |

| 22 | 0.71 | 0.711 | 0.70 |

Related Names

Zinc Coated Steel Wire | Galvanised Steel Wire Manufacturer | Corrosion Resistant Metal Wire

Links:https://www.globefindpro.com/products/83853.html

-

YH-Ⅲ Aseptic Vertical Form Fill Seal Machine for Pillow Packs

YH-Ⅲ Aseptic Vertical Form Fill Seal Machine for Pillow Packs

-

YHGZFJ-A-4 Liquid Filling Machine

YHGZFJ-A-4 Liquid Filling Machine

-

Belt Conveyor

Belt Conveyor

-

Reinforced Pipe

Reinforced Pipe

-

High Shear Emulsifier

High Shear Emulsifier

-

Volumetric Liquid Bottle Filling Machine

Volumetric Liquid Bottle Filling Machine

-

YHBBJ-A Automatic Liquid Filling and Sealing Machine

YHBBJ-A Automatic Liquid Filling and Sealing Machine

-

Aseptic Vertical Form Fill Seal Machine for Cartons

Aseptic Vertical Form Fill Seal Machine for Cartons

-

YHBBJ-B Automatic Liquid Filling and Sealing Machine

YHBBJ-B Automatic Liquid Filling and Sealing Machine

-

Welded Wire Mesh Panel

Welded Wire Mesh Panel

-

Gabion Cage

Gabion Cage

-

Aseptic Filling Line for Milk

Aseptic Filling Line for Milk