Volumetric Liquid Bottle Filling Machine

The volumetric liquid bottle filling machine is a PLC controlled liquid processing equipment which is designed with photoelectric sensor and pneumatic actuator to ensure high precision operation. It integrates a plastic bottle sealing machine to provide bottle sealing function. Due to this, it is also called bottle filling and sealing system.

The volumetric filling machine is mainly designed for food and beverage industries for bottling of distilled spirit, soy sauce, vinegar, plant oil, sugar syrup, mineral water, etc. It can also be utilized for filling of pesticides and chemicals in liquid.

The job of filling can be done perfectly under precise liquid level control without bubble and leakage.

User Friendly Designs

1. The volumetric liquid bottle filling machine is suitable for bottles with capacity from 50ml to 1000ml. It supports changing the filling volume within several minutes without using any additional tool, which makes it very efficient. The short filling cycle and large production capacity further ensures efficiency,

2. The volumetric liquid filling equipment can be designed with 6, 8, 10, or 12 filling heads, and offers filling capacity from 150 to 5000ml. Thus, clients can choose the filling head quantity and filling capacity according to specific application demands.

3. With touch screen control panel, the volumetric liquid bottle filling machine supports real time display of operation status, operation procedure, and filling parameters.

4. Each filling head is available with a bottle neck clamping device to ensure accurate filling.

5. The bottle filling and sealing machine feeds and outputs bottles in linear direction and grouped method. This makes it compatible with bottles in variety of shapes.

6. The world class pneumatic filling valve makes sure that there is no leakage or effusion. The user friendly HMI with PLC system helps to fulfill throughout precise control.

Precision Filling

1. The volumetric liquid bottle filling machine features fixed liquid flow. Thus, it realizes filling capacity adjustment through filling time regulation.

2. The working time of pneumatic valve can be accurate to 0.01 second, so the liquid level control error can be lowered to 1%. This is meaningful to reduce the waste.

3. Each of the filling head can be adjusted independently, so as to realize consistent filling capacity among all filling heads.

4. In addition to automatic bottle feeding function, the liquid packaging equipment also have automatic stop function when there is no bottle detected, or the actual bottle quantity is inconsistent with the preset one.

5. After rough adjustment, the filling capacity can be micro-adjusted as well to further ensure filling precision.

Technical Parameters

| Filling capacity | 150-5000ml |

| Power | 2KW |

| Production speed | 500-3000/h (heads) |

| No. of filling head | 6.8.10 .12 |

| Bottle height | 100-320mm |

| Bottleneck size | Φ 16mm (minimum) |

| Filling precision | ± 1% |

| Pneumatic pressure | 0.3m3 /min, 0.6-0.8Mpa |

| Dimensions | 5400(7400)×800×1850(mm) |

Links:https://www.globefindpro.com/products/83859.html

-

Rotary Liquid Filler

Rotary Liquid Filler

-

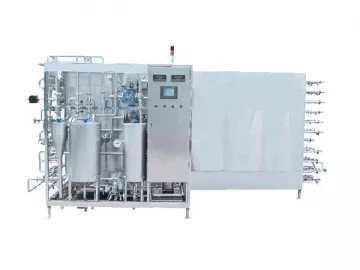

UHT Pilot Plant

UHT Pilot Plant

-

YH-D-3 Vertical Form Fill Seal Machine

YH-D-3 Vertical Form Fill Seal Machine

-

YHGZFJ-A-8 Liquid Filling Machine

YHGZFJ-A-8 Liquid Filling Machine

-

UHT Plant for Aseptic Packaging

UHT Plant for Aseptic Packaging

-

Crimped Wire Mesh

Crimped Wire Mesh

-

High Shear Emulsifier

High Shear Emulsifier

-

Reinforced Pipe

Reinforced Pipe

-

Belt Conveyor

Belt Conveyor

-

YHGZFJ-A-4 Liquid Filling Machine

YHGZFJ-A-4 Liquid Filling Machine

-

YH-Ⅲ Aseptic Vertical Form Fill Seal Machine for Pillow Packs

YH-Ⅲ Aseptic Vertical Form Fill Seal Machine for Pillow Packs

-

Galvanized Steel Wire

Galvanized Steel Wire