YH-D-3 Vertical Form Fill Seal Machine

This model of vertical form fill seal machine supports using packaging materials such as paper-plastic laminated material and paper-aluminum foil laminated material. During heat sealing of middle seal, an additional PE strip is available to enhance sealing quality.

The packaging material delivery system for the automatic liquid filling system adopts the double roller, double cutter, and a traction unit to balance the pressure during the delivery. This eliminates the demand for manual adjusting, and also ensures good appearance of finished package.

Through integrated control, the vertical form fill seal machine is available with photoelectric tracking function. It supports automatic alarming and stopping when there is shortage of packaging film or liquid.

According to client-side demands, the liquid filling machine can be designed with an aseptic processing system to extend the shelf life of various liquids.

Technical Parameters| Power | 1.6kw |

| Power supply | 220V/50HZ |

| Production rate | 1000-2000 bags/h |

| Bag size | 150-500 ml/bag |

| Filling method | Constant pressure filling |

| Filling preciseness | ±1.5% |

| Pneumatic power | 0.4m3/min/0.6-0.8Mpa |

| Gross weight | 780kg |

| Dimensions | 1850×1060×2500mm(L×W×H ) |

Links:https://www.globefindpro.com/products/83862.html

-

YHGZFJ-A-8 Liquid Filling Machine

YHGZFJ-A-8 Liquid Filling Machine

-

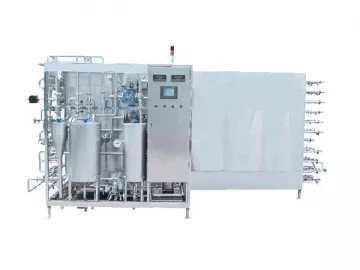

UHT Plant for Aseptic Packaging

UHT Plant for Aseptic Packaging

-

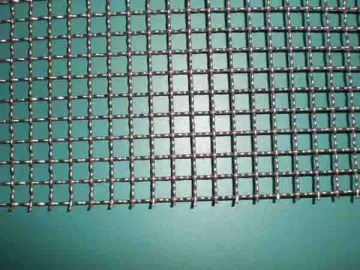

Crimped Wire Mesh

Crimped Wire Mesh

-

Lead Compound PVC Stabilizer

Lead Compound PVC Stabilizer

-

Automatic Premade Standup Pouch Filling Machine

Automatic Premade Standup Pouch Filling Machine

-

Automatic Bottle Filling Machine

Automatic Bottle Filling Machine

-

UHT Pilot Plant

UHT Pilot Plant

-

Rotary Liquid Filler

Rotary Liquid Filler

-

Volumetric Liquid Bottle Filling Machine

Volumetric Liquid Bottle Filling Machine

-

High Shear Emulsifier

High Shear Emulsifier

-

Reinforced Pipe

Reinforced Pipe

-

Belt Conveyor

Belt Conveyor