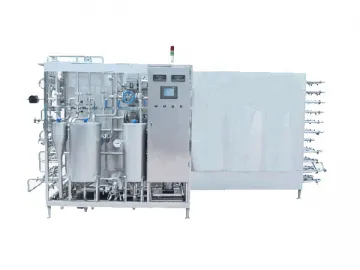

UHT Plant for Aseptic Packaging

The UHT plant is applicable for liquids with high viscosity and PH value from 1 to 14. It is usually used before an aseptic filling machine, and is a great sterilization solution for foods such as milk, yoghourt, soymilk, fruit juices, cream, wine, soups, honey, and stews. UHT products are typically aseptically packed to ensure a long shelf life up to 3 to 6 months without needing of preservatives or refrigeration.

Design Features

1. Based on our innovative technologies, our range of UHT processing line feature very low energy consumption, consistent stable operation, and low maintenance cost.

2. Our range of UHT plant is a piece of fully automated sterilization equipment. The entire ultra-heat treatment process including the sterilization temperature is PLC controlled.

3. Inside the heating pipes, there are no dead points and thus, the liquids won't stick on the pipe wall. Additionally, during the ultra high temperature sterilization, the corrugated pipe helps to form turbulent flow, so that the UHT plant is provided with self cleaning function. The pollution inside the pipe is avoided.

4. The UHT system is easy for assembly and disassembly as well as maintenance. The superior quality raw materials allow the liquid processing equipment to bear high pressures.

Technical Parameters

| Model | YHG2-G | Capability of processing | 2-3T/H |

| Dimensions | 4500×1700×2100cm | Net weight | 1500Kg |

| Heat utilization efficiency | ≥90% | Sterilization temperature / period | 137-142℃/ 6 seconds |

| Total power | 6.2KW | Rated voltage | 380V 50Hz |

Links:https://www.globefindpro.com/products/83864.html

-

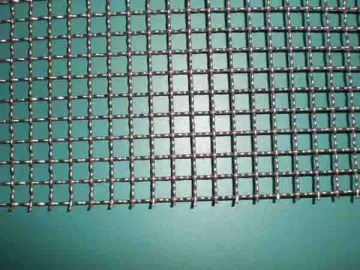

Crimped Wire Mesh

Crimped Wire Mesh

-

Lead Compound PVC Stabilizer

Lead Compound PVC Stabilizer

-

Automatic Premade Standup Pouch Filling Machine

Automatic Premade Standup Pouch Filling Machine

-

Automatic Bottle Filling Machine

Automatic Bottle Filling Machine

-

YH-IB Vertical Form Fill Seal Machine

YH-IB Vertical Form Fill Seal Machine

-

Chain Link Wire Mesh

Chain Link Wire Mesh

-

YHGZFJ-A-8 Liquid Filling Machine

YHGZFJ-A-8 Liquid Filling Machine

-

YH-D-3 Vertical Form Fill Seal Machine

YH-D-3 Vertical Form Fill Seal Machine

-

UHT Pilot Plant

UHT Pilot Plant

-

Rotary Liquid Filler

Rotary Liquid Filler

-

Volumetric Liquid Bottle Filling Machine

Volumetric Liquid Bottle Filling Machine

-

High Shear Emulsifier

High Shear Emulsifier