YH-IB Vertical Form Fill Seal Machine

The YH-IB vertical form fill seal machine is an efficient and automatic liquid packaging system for soy sauce, vinegar, liquor, milk, and other edible liquids.

Advantages

1. This range of liquid filling machine adopts a single-cam mechanism for system control, and offers uniform sealing temperature due to the double rollers for horizontal or vertical sealing. This makes it convenient for operation and simple for maintenance.

2. The vertical form fill seal machine is applicable for various types of packaging materials, including multi-layer laminate material, oxygen barrier type, high temperature resistant type and high pressure resistant PE film.

3. The heat sealing temperature is under the control of a precision microcomputer control panel, and the liquid packaging equipment supports sealing in multiple way, including three-side sealing, back sealing, and four-side sealing.

4. The packaging material delivery system is available with a touch screen computer control system, and a photoelectric tracking unit to ensure precision operation. This makes sure all packages have complete printed patterns and beautiful appearance. Additionally, the vertical form fill sealing machine is available with bag length presetting and quantity display functions. It also alarms when the computer controlled length is different from the length detected by the photoelectric tracking unit.

5. The liquid processing machinery supports production date marking by steel letter stamping or thermal transfer ribbon printing methods.

Technical Parameters

| Power | 1 kw |

| Power supply | 380V N/220V |

| Production rate | 20-30 bags/min |

| Packing size | 100-1000 ml / bag |

| Filling mode | Constant pressure filling |

| Filling accuracy | ±1.5% |

| Width of membrane | 320mm(Max.) |

| Weight | 235 kg |

| Dimensions | 700×660×2000mm(L × W × H) |

Links:https://www.globefindpro.com/products/83869.html

-

Chain Link Wire Mesh

Chain Link Wire Mesh

-

Ice Ball Making Machine

Ice Ball Making Machine

-

YHGZFJ-B-8 Liquid Filling Machine

YHGZFJ-B-8 Liquid Filling Machine

-

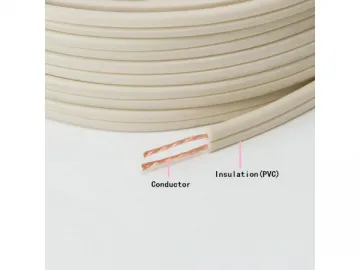

Speaker Cable (Audio Cable)

Speaker Cable (Audio Cable)

-

Fire Resistant PVC Insulated and Sheathed Control Cable

Fire Resistant PVC Insulated and Sheathed Control Cable

-

Rechargeable Heated Insole

Rechargeable Heated Insole

-

Automatic Bottle Filling Machine

Automatic Bottle Filling Machine

-

Automatic Premade Standup Pouch Filling Machine

Automatic Premade Standup Pouch Filling Machine

-

Lead Compound PVC Stabilizer

Lead Compound PVC Stabilizer

-

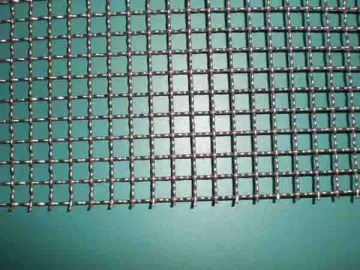

Crimped Wire Mesh

Crimped Wire Mesh

-

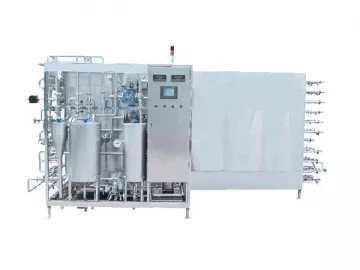

UHT Plant for Aseptic Packaging

UHT Plant for Aseptic Packaging

-

YHGZFJ-A-8 Liquid Filling Machine

YHGZFJ-A-8 Liquid Filling Machine