Rubber Predispersed Masterbatch S

| Name | S-75 | S-80 |

| Composition | 75% Sulfur powder 25% Ethylene-propylene rubber carrier and surface active dispersing agent | 80% Sulfur powder 20% Ethylene-propylene rubber carrier and surface active dispersing agent |

| Appearance | Yellow granules | Yellow granules |

| Density | 1.45 ± 0.05g/cm3 (25℃) | |

| Mooney viscosity(100℃) | 20 ± 5 |

Technical Feature

As the vulcanizing agent of natural rubber and dienes synthetic rubber, the predispersed masterbatch S can quickly blend into the rubber materials and disperses evenly. Uniform dispersion can avoid partial over-vulcanization, thus improving aging performance and dynamic fatigue performance of the rubber. In soft rubber materials, the good dispersion ability seems particularly important, as common sulfur powder is hard to disperse evenly in them. In addition, with the excellent dispersion performance, the pre-dispersed S can prevent brown sulfur spots arising on the surface of the light-colored vulcanized rubber, reducing product defects.

Processing

Powdery sulfur powder is likely to fly and adhere to the device. It is difficult to disperse evenly during mixing, thus resulting in defects of the rubber products. But the pre-dispersed S is easy to mix. It will not agglomerate under normal storage conditions. It has good flowability and there is no dust flying during mixing. The capability of blending into various rubber materials quickly and dispersing evenly ensures the optimum activity of the effective ingredient.

Application

Rubber products exposed to dynamic stress, various soft rubber materials, and light-colored rubber materials allowing no sulfur defects

Packaging

Calcium plastic box lined with polyethylene bag, 20kg/box

Storage

Stored in a cool, dry place; sealed storage for 24 months with original packaging

Related Names

Additive Master Batch Supplier | Rubber Accessories Production | Material Processing

Links:https://www.globefindpro.com/products/84006.html

-

SBG200 HDPE/PP Double Wall Corrugated Pipe Extrusion Line

SBG200 HDPE/PP Double Wall Corrugated Pipe Extrusion Line

-

Plastic Pipe Cutting Machine

Plastic Pipe Cutting Machine

-

SBG250 UPVC Double Wall Corrugated Pipe Extrusion Line

SBG250 UPVC Double Wall Corrugated Pipe Extrusion Line

-

Insulated Water Supply Corrugated Pipe Extrusion Line

Insulated Water Supply Corrugated Pipe Extrusion Line

-

Single Screw Extruder

Single Screw Extruder

-

Construction Machinery Rim

Construction Machinery Rim

-

Rubber Predispersed Masterbatch ZnO

Rubber Predispersed Masterbatch ZnO

-

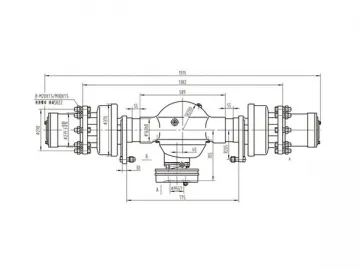

5T/6T Forklift Truck Axle

5T/6T Forklift Truck Axle

-

Rubber Predispersed Masterbatch IS

Rubber Predispersed Masterbatch IS

-

Rubber Predispersed Masterbatch NOBS-70

Rubber Predispersed Masterbatch NOBS-70

-

Rubber Predispersed Masterbatch TMTD

Rubber Predispersed Masterbatch TMTD

-

Paraquat

Paraquat