Ф300-Ф3000mm HDPE Steel Band Reinforced Spiral Pipe

This Ф300-Ф3000mm HDPE steel band reinforced spiral pipe integrates the corrosion resistance of plastics with strong toughness of steel. It offers such characteristics as high ring stiffness, high reliability, light weight, easy installation, wonderful sealing performance, low-cost transportation and construction, strong corrosion resistance, and extremely strong load capacity, among others. It is a new type pipe vigorously promoted by the national and local administrative departments.

As underground drainage pipe, our HDPE steel band reinforced spiral pipe can be widely applied in the gravity transportation of different corrosive or non-corrosive media, such as urban sewage, industrial sewage, rainwater, water source, agricultural irrigation, as well as the sewage from bridges, culverts, and roads, among others. With a broad market prospect, this pipe is the first choice product for the national key construction projects. It must lead the trend of our Chinese underground drainage pipe.

Pipe Connection Methods

Connection methods of this HDPE steel band reinforced spiral pipe is mainly divided into five types, including butt fusion welding type, socket type, thermal shrinkable sleeve type, electric melting band type, as well as stainless steel loop type.

| Item | Experiment Conditions | Demand | |

| Sealing Performance of Clamp Style Flexible Joint | Condition B: Radial deformation Pipe Deformation: 10% Stainless Steel Clamp: 5% Temperature: 23℃±2℃ | Lower Internal Hydrostatic Pressure (15min) 0.005MPa | No leakage |

| Higher Internal Hydrostatic Pressure (15min) 0.05MPa | No leakage | ||

| Internal Air Pressure (15min)- 0.03MPa | ≤-0.027MPa | ||

| Sealing Performance of Socket Joint | Condition C: Angular deflection DN/ID≤300: 2 400≤DN/ID≤600: 1.5° DN/ID>600: 1° Temperature: 23℃±2℃ | Lower Internal Hydrostatic Pressure (15min) 0.005MPa | No leakage |

| Higher Internal Hydrostatic Pressure (15min) 0.05MPa | No leakage | ||

| Internal Air Pressure (15min)- 0.03MPa | ≤-0.027MPa | ||

| Sealing Performance of PE Heat Shrink Tubing (Band) Joint | Lower Internal Hydrostatic Pressure (15min) 0.005MPa | No leakage | |

| Higher Internal Hydrostatic Pressure (15min) 0.05MPa | No leakage | ||

| Internal Air Pressure (15min)- 0.03MPa | ≤-0.027MPa | ||

| Tensile Strength of Electric Melting Band in Cold Wind | The minimum tensile strength should accord with the requirement of tensile strength of seam in Table 6. | ||

Physical Performance Index

| Item | Indicator | Test Methods | |

| Ring Stiffness (KN/㎡) | SN4 | ≥4 | GB/T9647 |

| SN8 | ≥8 | ||

| Ring Flexibility | When the amount of deformation is 30%, no cracking will occur. | GB/T9647 | |

| Longitudinal Shrinkage Rate | ≤3% | GB/T6671.2 | |

| Drop-Hammer Impact | The inner wall has no cracks, and no disengagement is found between two walls. | GB/T14152 | |

| Joint-Part Seal Test | No leakage | GB/T6111 | |

| Tensile Strength of Seam | It reaches the specified value. | GB/T19272.2 | |

Main Specifications

| Nominal SizeDN/ID | Min. Average Inside Diameter | Min. Thickness of Inner Wall | Ring Stiffness and Steel Band Parameters | |||||

| SN8 | SN12.5 | SN16 | ||||||

| Min. Thickness | Min. Height | Min. Thickness | Min. Height | Min. Thickness | Min. Height | |||

| 300 | 294 | 2.5 | 0.5 | 12 | 0.6 | 14 | 0.7 | 18 |

| 400 | 392 | 2.5 | 0.5 | 12 | 0.6 | 14 | 0.7 | 18 |

| 500 | 490 | 3.5 | 0.6 | 14 | 0.7 | 16 | 0.7 | 20 |

| 600 | 588 | 3.5 | 0.6 | 16 | 0.7 | 16 | 0.8 | 20 |

| 700 | 685 | 3.5 | 0.6 | 16 | 0.7 | 18 | 0.8 | 20 |

| 800 | 785 | 5 | 0.8 | 20 | 1 | 20 | 1 | 24 |

| 900 | 885 | 5 | 0.8 | 22 | 0.8 | 24 | 1 | 26 |

| 1000 | 985 | 5 | 0.8 | 24 | 0.8 | 26 | 1 | 30 |

| 1100 | 1085 | 5 | 1 | 24 | 1 | 26 | 1 | 30 |

| 1200 | 1185 | 5 | 1 | 24 | 1 | 26 | 1 | 30 |

| 1300 | 1285 | 5 | 0.8 | 30 | 1 | 32 | 1 | 36 |

| 1400 | 1385 | 5 | 0.8 | 30 | 1 | 30 | 1 | 36 |

| 1500 | 1485 | 5 | 0.9 | 30 | 1 | 32 | 1 | 36 |

| 1600 | 1585 | 5 | 1 | 30 | 1 | 32 | 1 | 36 |

| 1800 | 1785 | 6 | 1 | 34 | 1 | 36 | 1 | 42 |

| 2000 | 1985 | 6 | 1 | 36 | 1 | 40 | 1 | 42 |

| 2200 | 2185 | 7 | 0.8 | 42 | 1 | 42 | 1 | 48 |

| 2400 | 2385 | 7 | 1 | 42 | 1 | 44 | 1 | 48 |

| 2600 | 2585 | 8 | 1 | 44 | 1 | 48 | 1.2 | 48 |

| 2800 | 2785 | 8 | 1 | 48 | 1.2 | 48 | 1.2 | 52 |

| 3000 | 2985 | 8 | 1.2 | 48 | 1.2 | 54 | 1.5 | 54 |

Related Names

Reinforced Water Pipe Manufacturer | Durable Buried Drain Line | Plastic Tube

Links:https://www.globefindpro.com/products/84014.html

-

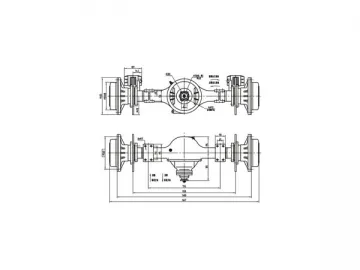

1.0-2.0T Drive Axle

1.0-2.0T Drive Axle

-

Conical Twin Screw Extruder

Conical Twin Screw Extruder

-

SBG500 UPVC Double Wall Corrugated Pipe Extrusion Line

SBG500 UPVC Double Wall Corrugated Pipe Extrusion Line

-

PE Communication Pipe

PE Communication Pipe

-

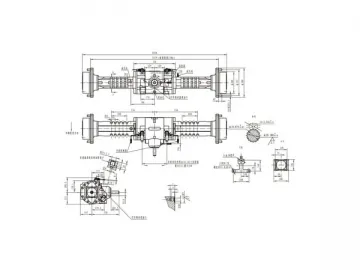

WZD75 Loader-Digger Drive Axle

WZD75 Loader-Digger Drive Axle

-

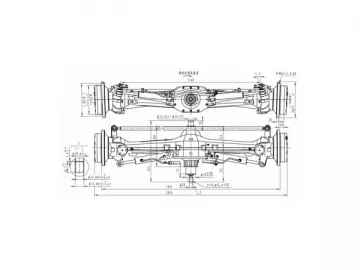

Wet Brake Drive Axle

Wet Brake Drive Axle

-

120 Horsepower Four-wheel Drive Tractor Axles

120 Horsepower Four-wheel Drive Tractor Axles

-

Construction Machinery Rim

Construction Machinery Rim

-

Single Screw Extruder

Single Screw Extruder

-

Insulated Water Supply Corrugated Pipe Extrusion Line

Insulated Water Supply Corrugated Pipe Extrusion Line

-

SBG250 UPVC Double Wall Corrugated Pipe Extrusion Line

SBG250 UPVC Double Wall Corrugated Pipe Extrusion Line

-

Plastic Pipe Cutting Machine

Plastic Pipe Cutting Machine