Rubber Predispersed Masterbatch CBS

| Composition | 80% N-cyclohexane-2 - benzothiazolyl sulfenamide 20% Ethylene-propylene rubber carrier and surface active dispersing agent |

| Appearance | Gray particle |

| Density | 1.10 ± 0.05 g/cm3 (25℃) |

| Mooney viscosity (70℃) | 25±5 |

Technical Feature

The predispersed masterbatch CBS extends the scorch time of the rubber, makes the rubber safer to process, and accelerates the vulcanization of the rubber. It can be used alone in low sulfur vulcanization or used together with dithiocarbamates or thiurams accelerators. The obtained vulcanized rubber has excellent anti-aging properties and resistance to compression set. Thiourea type accelerator has obvious secondary promotion effect on the pre-dispersed masterbatch CBS, especially in low sulfur rubber compounds. In rubber materials containing thiols accelerating agent and thiurams accelerator, our product can delay scorch and improve processing security.

Processing

The pre-dispersed CBS will not agglomerate under normal storage conditions. It is easy to weigh and mix. It has good fluidity with no dust flying. It disperses evenly in various rubber materials. Active ingredient is effectively guaranteed. Defects of the finished rubber products are reduced and dynamic performance of the products are improved. In addition, since our product has been pre-dispersed, it is suggested to add it in the late stage of the mixing process.

Application

Extruded products (sealing strip, rubber tube), rubber belt, conveyor belt, rubber roll, cable jacket, rubber flooring

Packaging

20kg/bin, plastic bin lined with polyethylene bag

Storage

Stored in a cool, dry place. Original packaging sealed storage for 6 months

Related Names

Accelerator Masterbatch Supplier | Dispersing Additives | Rubber Device Making

Links:https://www.globefindpro.com/products/84035.html

-

Rubber Predispersed Masterbatch DPTT-75

Rubber Predispersed Masterbatch DPTT-75

-

Rubber Predispersed Masterbatch BZ-75

Rubber Predispersed Masterbatch BZ-75

-

Rubber Predispersed Masterbatch TMTM

Rubber Predispersed Masterbatch TMTM

-

Rubber Accelerator DPG/D

Rubber Accelerator DPG/D

-

Digital Food Scale

Digital Food Scale

-

Rubber Antiscorching Agent CTP(PVI)

Rubber Antiscorching Agent CTP(PVI)

-

Rubber Predispersed Masterbatch ETU-75

Rubber Predispersed Masterbatch ETU-75

-

Rubber Accelerator ZDEC/EZ

Rubber Accelerator ZDEC/EZ

-

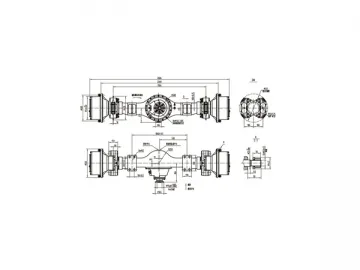

3T/6T/8T Drive Axle

3T/6T/8T Drive Axle

-

Road Roller Drive Axle

Road Roller Drive Axle

-

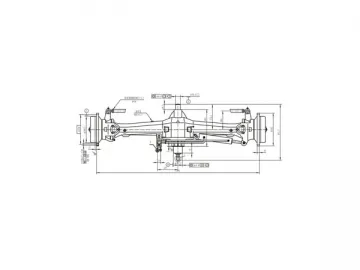

80-90 Horsepower Tractor Front Axle

80-90 Horsepower Tractor Front Axle

-

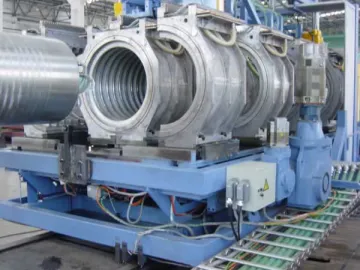

SBG1000 UPVC Double Wall Corrugated Pipe Extrusion Line

SBG1000 UPVC Double Wall Corrugated Pipe Extrusion Line