Rubber Predispersed Masterbatch BZ-80

| Product name | ZDBC-75 | ZDBC-80 |

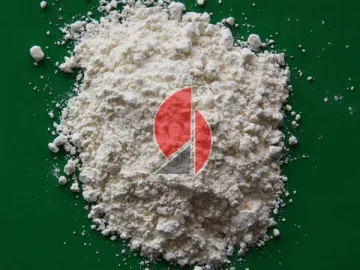

| Composition | 75% Zinc dibutyl dithiocarbamate 25% Ethylene-propylene rubber carrier and surface active dispersing agent | 80% Zinc dibutyl dithiocarbamate 20% Ethylene-propylene rubber carrier and surface active dispersing agent |

| Specification | 20kg/box | 20kg/box |

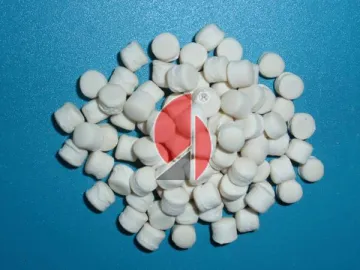

| Appearance | White to off-white granules | White to off-white granules |

Product Feature

The predispersed masterbatch BZ-80 speeds up the vulcanization of natural rubbers, SBR, NBR, and EPDM. Compared with pre-dispersed ZDEC-80, ZEPC-80 and ZDMC-80, this product gives shorter scorch time and longer vulcanization time. Alkaline accelerators can activate this product. A small amount of pre-dispersed ZDBC can be used as the secondary accelerator for thiols or thiuram accelerators. The obtained vulcanized rubber has good tensile strength and resilience performance. When used together with antioxidant in NR and IR, this product can improve the heat resistance.

Processing Advantage

Powdery ZDBC accelerator is easy to agglomerate and difficult to disperse evenly, resulting in reduced curing activity and degraded mechanical properties. However, the pre-dispersed ZDBC with precisely controlled particle size is able to blend into various rubbers easily and disperse evenly, which ensures the optimal activity of the ZDBC. In addition, the pre-dispersed ZDBC is granular, thus avoiding powder flying or material loss. The stability and uniformity of different batches of rubber compounds are improved. It is suggested to add this product in the late stage of mixing.

Application

EPDM sealing strip, industrial rubber products, rubber shoes, cables, etc.

Packaging

Calcium plastic box, 20kg/box

Storage

Store the product in cool, dry places.

12 months in original closed container

Related Names

BZ Particle Manufacturer | Rubber Dispersion | Grain in Rubber Industry

Links:https://www.globefindpro.com/products/84055.html

-

Rubber Vulcanizing Agent

Rubber Vulcanizing Agent

-

Rubber Accelerator DCBS/DZ

Rubber Accelerator DCBS/DZ

-

Rubber Predispersed Masterbatch DPG

Rubber Predispersed Masterbatch DPG

-

Rubber Predispersed Masterbatch MBT

Rubber Predispersed Masterbatch MBT

-

Rubber Accelerator MBTS/DM

Rubber Accelerator MBTS/DM

-

Pneumatic Reservoir

Pneumatic Reservoir

-

Rubber Accelerator ZDBC/BZ

Rubber Accelerator ZDBC/BZ

-

Rubber Accelerator MBT/M

Rubber Accelerator MBT/M

-

Rubber Accelerator TMTM/TS

Rubber Accelerator TMTM/TS

-

Rubber Accelerator TMTD/TT

Rubber Accelerator TMTD/TT

-

Multifunction Kitchen Scale

Multifunction Kitchen Scale

-

Rubber Predispersed Masterbatch MBTS

Rubber Predispersed Masterbatch MBTS