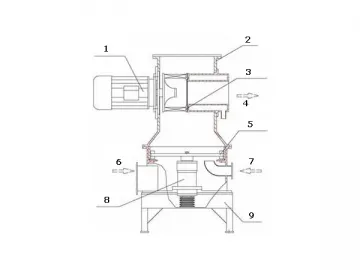

CSM-H Superfine Classifier Mill

Description

CSM-H superfine classifier mill is similar to the German Alpine ZPS or domestic CWJ micro pulverizer. The machine is primarily applied to smash the material with hardness below 3.5Mohs, for obtaining the superfine powder of 5 to100μm. A large amount of cooling air can be used for smashing thermal sensitive material.

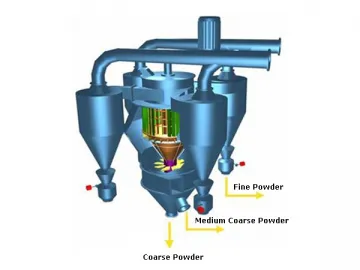

Working Principle

The upper part of the machine's cylindric inner cavity is the ultramicro powder grader, while the lower part is the ultramicro powder grinder. With the smashing disc and abrasive disk, the smashing system is fit for crushing the material into fine powder. The grading system applies the impeller to separate the powder according to the fineness. The powder with qualified fineness will be gathered by the cyclone collector after expelled from the discharge tube. Meanwhile, the unqualified powder will go back to the smashing area for continuously grinding.

Different driving devices are used to respectively drive the smashing disc and grading impeller. The product fineness can be adjusted via adjusting the rotate speed of the grading impeller. A screw feeder is installed to the side wall of the machine, for uniformly feeding the material to the smashing system. Moreover, the feeding amount can be carried out by adjusting the rotating speed.

Technical Features

1. The CSM-H superfine classifier mill is integrated with the impact superfine grinder and high-efficient turbine superfine grader. Under the effect of the airflow, the material after smashed will be graded by the turbine superfine grader. With the grading device rather than the general type grinder screen, the machine features high smashing efficiency since it can synchronously accomplish both smashing and grading tasks.

2. Through adjusting the speed of the grading impeller, you can adjust the product fineness without stopping the machine.

3. When smashing, the powerful airflow offers the excellent cooling performance. Due to the low temperature rise, our machine is particularly applicable for processing heat sensitive or fibrous material into the powder with uniform particle sizes.

| 1. High Speed Motor2. Cavity3. Grading Device4. Finished Product5. Smashing Device6. Air7. Raw Material8. Bearing Pedestal9. Engine Base | ||

| Model / Item | CSM-280 | HCSM-400 | HCSM-630 | HCSM-800 | HCSM-1000 | HCSM-1250H | |

| Diameter of Smashing Disk | 280 | 400 | 630 | 800 | 1000 | 1250 | |

| Matched Power (KW) | Grinding Disk | 7.5 | 18.5 | 30 | 45~55 | 132 | 75~90 |

| Grading Impeller | 4 | 4 | 11~15 | 15 | 22 | 30 | |

| Feeder | 0.55~1.1 | ||||||

| Rotor Speed (r/min) | Smashing Disk | 7500 | 5250 | 7500 | 2625 | 2100 | 1700 |

| Grading Impeller | 1000~8500 | 800~6000 | 600~4000 | 500~3000 | 400~2250 | 300~2000 | |

| Feeder | 20~100 | ||||||

| Maxi. Air Flow (m3/h) | 500 | 1200 | 3000 | 4800 | 9000 | 12000 | |

| Grinding Fineness (m) | 5~300 | 10~300 | |||||

| Output (kg/h) | 2~120 | 15~600 | 25~1000 | 30~1500 | 60~2000 | 100~3000 | |

Application

Lithium Battery Graphite Anode

Biological Aquatic Feed

Carbon Dust

Organic and Inorganic Pigment

Limestone or Other Minerals

Inorganic Phosphate

Powder Coating

Sugar

Gelatin

Cocoa Cake

Cellulose Derivative

Metal Powder Compound

As an experienced superfine classifier mill manufacturer and supplier in China, It provides a wide range of products, including fiber pulverizer, spiral flow jet mill, powder mixing, drying and granulating equipment, powder grader, and much more.

Related Names

Superfine Grinding Mill | Hard Material Grinding Equipment | Long Service Life Classifier Mill System

Links:https://www.globefindpro.com/products/84283.html

-

Steel Track (51-150mm)

Steel Track (51-150mm)

-

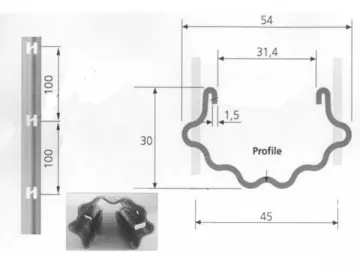

South American Style Steel Vineyard Stake

South American Style Steel Vineyard Stake

-

Slotted Track

Slotted Track

-

4.5mm Radius Render Corner Beads

4.5mm Radius Render Corner Beads

-

Hot Laminated Flex Backlit Banner

Hot Laminated Flex Backlit Banner

-

Multi-Blade Cutting Machine

Multi-Blade Cutting Machine

-

Coated Printable Backlit Flex Banner

Coated Printable Backlit Flex Banner

-

Large Capacity Powder Grading Machine

Large Capacity Powder Grading Machine

-

Laminated PVC Tarpaulin

Laminated PVC Tarpaulin

-

EP32 Cement Render Beads

EP32 Cement Render Beads

-

RTM Turbo Rotor Mill

RTM Turbo Rotor Mill

-

22mm Omega Furring Channel

22mm Omega Furring Channel