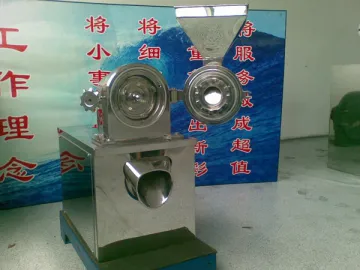

CXJ Fiber Pulverizer

The CXJ fiber pulverizer is chiefly used to cut fibrous materials or soft materials. To realize the maximum comminuting efficiency, you need to set the parameters, such as the number of the rotating blades, the amount of the fixed blades, rotor speed, and special screen. The rotor applies the open design to increase the air flow. With the feed inlet arranged in the center, the feed overload will be eliminated. When the tailor-made feeding system is installed onto the top feed inlet, continuously feeding the products of roll form can be realized.

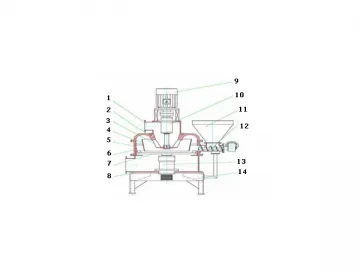

Working Principle

Devised with the advanced aerodynamics and bionics, the pulverizer is comprised of high speed moving cutter and fixed cutter, with both of which a special shear angle is formed. Via the speedily cutting, this machine can efficiently, finely smash all kinds of fibers with low power consumption.

Structural Feature

a. With high-precision cutting and grinding functions, the fiber pulverizer can quickly cut and shatter the fiber or other similar materials. The material fineness ranges from 0.1mm to 3mm.

b. It realizes the smashing through the blade inside the fixed device as well as the rotary cutting blade.

c. The materials fineness is depended on the screen which is installed in the lower part of the grinding area.

d. Feeding is achieved by means of the gravity or rolling system.

e. Both the moving cutter and fixed cutter can adopt different types of blades.

f. Our machine applies the open type rotor structure to ensure the smashing efficiency.

| Model | CXJ-500/750 | CXJ-500/100 | CXJ-500/1500 |

| Rotor Diameter (mm) | 500 | ||

| Length of the Fixed Cutter (mm) | 750 | 100 | 1500 |

| Rotor Speed (r/min) | 750-1100 | ||

| Crushing Fineness (mesh) | 20-325 | ||

| Output (kg/h) | 30-300 | 50-400 | 100-800 |

| Mating Power (kw) | 55 | 75 | 110 |

Application

This pulverizer can be used for aramid fiber, starch, leather, textile, mineral fiber, carbon fiber, paper, plastic, etc.

As a China-based fiber pulverizer manufacturer and supplier, It offers a broad range of products, including turbo rotor mill, powder mixing, drying and granulating equipment, fluidized bed jet mill, vacuum conveyor, and more.

Related Names

High Accuracy Fiber Crushing | Fiber Cutting Equipment | Fiber Mill

Links:https://www.globefindpro.com/products/84298.html

-

MQW Fluidized Bed Jet Mill

MQW Fluidized Bed Jet Mill

-

Manual Edge Cutting Machine

Manual Edge Cutting Machine

-

WDJ Turbo Mill

WDJ Turbo Mill

-

Four-Cylinder Hydraulic Stone Cutter

Four-Cylinder Hydraulic Stone Cutter

-

Edge Grinder

Edge Grinder

-

CUM Impact Mill

CUM Impact Mill

-

RLM Superfine Roller Mill

RLM Superfine Roller Mill

-

MQL Spiral Flow Jet Mill

MQL Spiral Flow Jet Mill

-

Tip for Mining

Tip for Mining

-

Hydraulic Double-Column Stone Cutter

Hydraulic Double-Column Stone Cutter

-

CSM-V Superfine Classifier Mill

CSM-V Superfine Classifier Mill

-

Single Blade Hydraulic Stone Cutter

Single Blade Hydraulic Stone Cutter