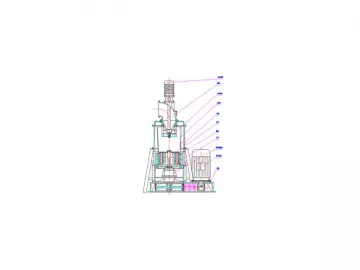

Four-Cylinder Hydraulic Stone Cutter

Structural Characteristics

1. The multi-blade four-cylinder marble and granite stone cutting machine chooses four fully closed columns as guide rail for lifting to make it more stably at optimized status for a long time.

2. The hydraulic cylinder takes place of the conventional lead screw for lifting, reducing the mechanical abrasion, repairing cost and time, as well as the production cost on the product. Meanwhile, the trolley is drawn by the hydraulic cylinder instead of traditional speed reducer. Therefore, the product is stable, long lasting and it needs no frequent maintenance.

3. The motor driven automatic slice separating increases the precision and efficiency of the product, decreasing the labor intensity.

| Item | unit | SDB 1600D- 18 | SDB 1600D-22 | SDB 1600D-22 |

| Diameter of blade | mm | Φ940- Φ1600/2200 | Φ940- Φ1600/2200 | Φ940- Φ600/2200 |

| Quantity of blade | pc | 18 | 22 | 24 |

| Lifting stroke of blade | mm | 1150 | 1150 | 1150 |

| Cutting dimension | mm | 3500×1550×950 | 3500×1600×950 | 3500×1650×950 |

| Power of main motor | kw | 75/90 | 110 | 132 |

| Total power | kw | 94.2 | 114.2 | 136.2 |

| Water consumption | L/min | 320 | 350 | 380 |

| Total weight | kg | 9500 | 10000 | 11000 |

| Overall dimension | mm | 8600×5000×6000 | 8600×5000×6000 | 8600×5400×6000 |

We are an experienced four-cylinder hydraulic stone cutter manufacturer and supplier in China. Our products include multi-blade cutting machine, infrared bridge stone cutter, saw blades for mining machine, diamond wire saw, and much more.

Related Names

Four Columns Hydraulic Stone Processing Machine | Stone Cutting Device with Four Cylinders | Hydraulic Stone Slicing Equipment | Hydraulic Pressure Stone Cutter

Links:https://www.globefindpro.com/products/84302.html