ULM Rotor Mill

The advanced-level ULM rotor mill innovated through assimilating and absorbing the German advanced technology, is used to process micro powder. It is designed with the ultrasonic shattering and spraying functions. In addition to high-frequency vibration generation and continuous working, it also can synchronously implement both drying and shattering tasks.

As the all-purpose superfine-powder mill, our product offers an effective smashing solution to the special materials. It perfectly functions even to the thermal sensitive and low dissolution point materials, for instance, PVC, fibrous materials, magnesium metal, etc. Therefore, this machine is widely applied in the areas, including plastic, food, coloring matter, chemical industry, vegetable fiber, and more.

Working Principle

This ULM rotor mill smashes the materials, by virtue of the functions of the high-speed revolving rotor and the stationary dentiform lining circle. Apart from the impact grinding function, it also comes with excellent performances such as the advanced spaying high-speed vortex and ultrasonic impact crushing. The generated high-speed airflow can take away the heat produced by the grinding, thus avoiding the local overheating. For that reason, this machine is suited to smash the special or heat-sensitive materials.

The drying and grinding tasks can be simultaneously carried out as long as this type of machine is fed with hot air. Therefore, our rotor mill can produce fine powder with high efficiency. Also, it is capable of processing the wet materials. The smashing system applies the crushing rotor comprised of horizontal discs and vertical blades. The air inside the smashing system is flexible, and can slightly vibrate freely. When the rotor operating, the outer circumferential velocity is no less than 84 m/s, and the airflow velocity between the rotor and lining circle reaches 55 m/s. Due to the impact caused by airflow adjustment, about 4,000 to 15,000 times of microvibration will be generated. Thereby, 140db audible ultrasonic wave will be made in the system, and 0.025Pa pressure difference will be formed. Through this way, the jet flow and eddy current of the sonic velocity enables the particles to be smashed by mutual friction, collision. That's why our machine comes with the smashing efficiency and product fineness superior to the impact-type product.

The specially designed rotor is equipped with two draught fans, both of which are used to generated high-speed airflow. The lower draught fan is mainly used for the material suction, and the upper draught fan is mainly used for the material convey. The machine is also installed with overflow pipe, with which the unqualified particles can return back to the inlet for re-smashing. The materials after smashed will be conveyed to the cyclone collector by the airflow, and then discharged by the airlock rotary valve.

Technical Feature

1. Under the condition of the rated main engine rotational speed, the ULM rotor mill can smash the materials of no more than 2 or 3 Moh's hardness. When processing the organic products or superfine grinding the special material, the output varies according to the product and the fineness requirement. For smashing the materials of extremely low melting point, the cooling process system should be applied.

2. The vertical shaft-type main engine has no screen. Motors of different powers can be matched in accordance with the performance.

3. Through the static balance and the precise dynamic balancing tests, the rotors generate no vibration when operating. Therefore, our machine can be just placed on the level ground, or supported by the shockproof pad. You needn't lay the foundation or install the foundation bolt.

4. A complete set just requires one main engine. The new type pulse dust remover comes with the collection efficiency up to 99.5%. Meanwhile, the feeding device adopts the stepless speed regulating motor to control the feeding amount. The screw-type automatic feeding is used.

5. All the easy to wear parts are made of special wear-resistant steel.

6. This machine is available with two kinds of blades. You can choose the suitable blade according to different materials.

7. It is equipped with the grading disc to increase or decrease the number of the classification rods, and the product fineness can be thereby adjusted.

8. The overflow pipe has been installed to adjust the amount of reflux airflow. Thus, the product fineness can be adjusted without stopping the machine.

9. Furthermore, this rotor mill is easy in installation, and convenient in maintenance. Additionally, it is characterized by easy operation, convenient cleaning, continuous production, and large production capacity.

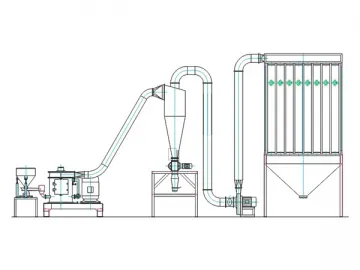

Structure Flow Chart

Parameters

| Model Item | Rotor Diameter(mm) | Matched Power (kw) | Rotate Speed (Maxi. r/min) | Maxi. Processing Airflow (m³/h) | Grinding Fineness(um) | Output (kg/h) |

| ULM-400 | 360 | 30~37 | 4600 | 1200 | 15~250 | 30~800 |

| ULM-600 | 540 | 45~55 | 3050 | 2000 | 80~2000 | |

| ULM-800 | 7830 | 75~90 | 2100 | 3000 | 100~3000 | |

| ULM-1200 | 1130 | 110~132 | 1480 | 7500 | 200~4500 |

Application

1. Bulk Drug, Chinese Herbal Medicine;

2. PP, PE Color Master Batch, PET, PS, PC;

3. Rubber, Artificial Fiber;

4. Food Gum, Guar Gum;

5. Detergent, Soda Ash;

6. Superfine Depolymerization and Surface Modification of Minerals

7. Chemical polymers

8. Magnesium particles

As a professional rotor mill manufacturer and supplier in China, we provide a wide range of products, including ultra-low temperature pulverizer, fluidized bed jet mill, disc jet mill, superfine powder classifier, and more.

Related Names

Rotary Mill | Drying and Crushing Equipment | Industrial Crushing Device

Links:https://www.globefindpro.com/products/84320.html

-

WZ30-25 Backhoe Loader

WZ30-25 Backhoe Loader

-

YN926 Wheel Loader

YN926 Wheel Loader

-

YN926 Mining Loader

YN926 Mining Loader

-

YZK-1500/2000 Hydraulic Stone Mining Machine

YZK-1500/2000 Hydraulic Stone Mining Machine

-

7041 Adjustable Temperature Hair Straightener

7041 Adjustable Temperature Hair Straightener

-

YN918 High Dump Loader

YN918 High Dump Loader

-

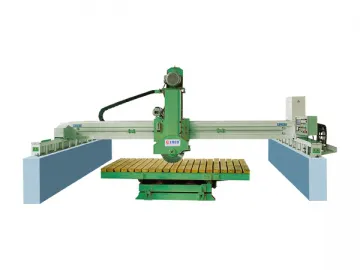

Infrared Bridge Stone Cutter

Infrared Bridge Stone Cutter

-

CW Double-Rotor Rod Mill

CW Double-Rotor Rod Mill

-

Surface Polishing Machine

Surface Polishing Machine

-

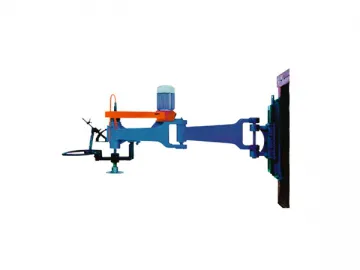

Water Pipe for Mining

Water Pipe for Mining

-

Continuous Polishing Machine

Continuous Polishing Machine

-

YZK-2600/3100 Hydraulic Stone Block Cutter

YZK-2600/3100 Hydraulic Stone Block Cutter