HOWO 70 Mining Dump Truck

The HOWO 70 mining dump truck, Mine Overlord, is developed by Sinotruk according to the features of the working conditions in the mines. It is suitable for the short-distance transport business in various wharves, steel mills, open pits, hydropower sites, and other places with harsh environment.

The Mine Overlord adopts a cab with high strength framework covered with protective materials. The cab is set with one side door. A high-power diesel engine is used. The heating device adopted makes it easier for the vehicle to start and provides heat to the cab in cold days. The cost-effective chassis brings customers with good economic efficiency and social effectiveness.

Features

1. The pre-filtration plus oil bath plus air filtration three-level air filter of the engine intake system is able to filter the dust effectively. This prevents the early wear of the engine and extends its service life.

2. The reinforced front and rear leaf springs enable the chassis to deal with various harsh working conditions.

3. The standard configuration includes a 200L cooling water tank and water spraying device which cool the braking system more quickly and conveniently, improving braking safety.

4. The HOWO 70 mining dump truck is equipped with the new front axle assembly which is independently developed by Sinotruk. It employs integrally cast I-beams, Φ500×210 reinforced type brake, and other assemblies or parts that are suitable for mine vehicles.

5. The AC26 drive axle is used as the rear axle. The main reducer is designed more reasonably. The reinforced type cast axle housing and drum brake make the carrying capacity and braking ability of our product in the leading domestic level.

6. The 10.0/2-25 wheel assembly is adopted. The 14.00-25-36PR tire is among the standard configuration, but the 14.00R25-36PR tire is optional. These tires with high load carrying capacity and wear resistance are specially tailored for Mine Overlord.

1. Cab

a. The HOWO 70 mining dump truck adopts a cab with high strength framework covered with protective materials. The cab is opened from one side. It can be turned forwards by 50°. The front and rear lighting work lights facilitate night operations. The cab interior is comfortable. The good sealing property ensures comfortable driving environment even when the vehicle works under harsh conditions.

b. Omni-directional vision, fully taking the vehicle width of 3300mm and complex working condition needs into account.

c. The door wind shutter, windshield, and right window have excellent defrosting function, making the Mine Overlord applicable to working in cold regions. When installing a separate fuel heating device, the defrosting performance is better. So far, the one-side-door cab from other manufacturers has basically no defrosting function or only the windshield has the function.

d. Air conditioning and heater are provided.

2. HF12 Front Axle Assembly

The HF12 fist-shaped front axle is a new assembly that is independently developed by Sinotruk for mine vehicles. It uses the integrally cast I-beam, Φ500×210 reinforced type brake, and other parts which are suitable for mine vehicles.

The first batch of sample of HF12 front axle achieves the desired objectives in the bench test. Compared with the HF9 front axle that is currently used by HOWO dump trucks, the HF12 front axle has higher carrying capacity and better braking performance. Its carrying capacity is increased by at least 1/3. Therefore, the HF12 front axle is more suitable for vehicles working in the mines with harsh working conditions.

3. AC26 Drive Axle

The AC26 integrally cast double reduction drive axle with wheel side reducer is independently developed by our company and is dedicated for mine vehicles. With reasonable design and advanced technology, the axle has high safety, strong carrying capacity, high strength, and high stiffness. It is able to adapt to the harsh working conditions in the mines.

Advantages

1. The main reducer is reasonably designed. The support stiffness is good. The combination of forced lubrication and splash lubrication makes the service life of the reducer improve greatly.

2. The reinforced type cast axle housing is reasonably structured. Its wall thickness transits uniformly and its bearing capacity is two times that of common STEYR double axle.

3. The reinforced type drum brake with the Φ500×235 ultra-wide brake shoe is adopted. It has reliable braking performance and long service life.

4. Adopting cross-mounted arrangement, the driving bevel gear's strength and stiffness are improved substantially.

4. Braking System and Cooling Device

Braking system: The front, middle, and rear axles all adopt 30inch dual-chamber brake compartment which has strong braking force.

Cooling device: The 200L cooling water tank meets the cooling needs when the vehicle under heavy load brakes in a long slope road. A water spraying device is attached.

Specifications

| Mass Parameters | Curb Weight (kg) | 29300 | |

| Maximum Permissible Total Mass (kg) | 70000 | ||

| Towable Mass of Trailer (kg) | |||

| Size Parameters | Overall Dimensions (mm) | Length | 8700, 8400 |

| Width | 3300 | ||

| Height | 4340 | ||

| Distance between Axles (mm) | 3800 1500, 3600 1500 | ||

| Minimum Ground Clearance (mm) | 340 | ||

| PerformanceParameters | Max. Driving Speed (km/h) | 50, 60 | |

| Economic Speed (km/h) | 35 | ||

| Max. Gradeability (%) | 42 | ||

| Minimum Turning Diameter (m) | 19 | ||

| RecommendedConfiguration | Engine | Model | WD615.96C |

| Net Power (kW)/ Rotational Speed (r/min) | 279kW/2000rpm | ||

| Max. Torque (Nm)/ Rotational Speed (r/min) | 1590/1200~1500 | ||

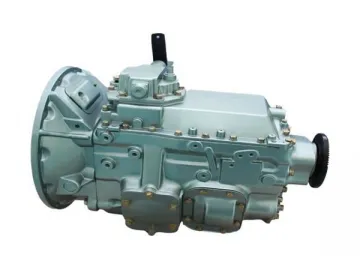

| Gearbox | HW19710, HW19710A | ||

| Clutch (mm) | 430A | ||

| Rear Axle | Model | AC26 | |

| Velocity Ratio | 10.47/8.51 | ||

| Oil Tank (L) | 500 | ||

| Frame Section (mm) | 380×120×10 | ||

| Suspension (front/rear spring) | 18×12/25×15 | ||

| Tire | 14.00-25, 14.00R25 | ||

Usage of Patents

| Patent Name | Type | Patent Number | |

| 1 | One-side-door cab which can be flipped | New type | ZL200820233338.1 |

| 2 | Cab for mine heavy-duty vehicle | New type | 201020300571.4 |

| 3 | Radiator cover for heavy mining vehicles | New type | 201020101426.3 |

| 4 | Right side platform assembly for heavy mining vehicles | New type | 201020101325.6 |

| 5 | Instrument sets of heavy duty truck cab | Appearance | 201030140919.3 |

| 6 | New suspension system | New type | ZL200920017240.7 |

| 7 | New front leaf spring rear bracket | New type | ZL200820026501.7 |

| 8 | Heavy duty truck cab rear-view mirror | Appearance | 200830354794.7 |

| 9 | Brake cooling device | New type | ZL200820016846.4 |

| 10 | Transmission | New type | ZL200720027568.8 |

| 11 | Pull-type diaphragm spring clutch assembly for heavy-duty vehicle | New type | 200920019097.5 |

| 12 | Cross beam assembly | Appearance | 200930261302.4 |

| 13 | New sliding ball joint assembly | New type | 200820226455.5 |

| 14 | Dump truck exhaust | New type | 200920239701.5 |

| 15 | Dump truck frame assembly | New type | 200920281955.3 |

| 16 | Baseboard heating device | New type | 200920312761.5 |

Related Names

Off-road Dumper Truck Supplier | Small Distance Mineral Transport | Mining Vehicle

Links:https://www.globefindpro.com/products/84573.html

-

HW10707T Series Medium Duty Auto Transmission

HW10707T Series Medium Duty Auto Transmission

-

Crane Truck

Crane Truck

-

DC6J65T Series Light Duty Auto Transmission

DC6J65T Series Light Duty Auto Transmission

-

Paper Faced Gypsum Partition Board

Paper Faced Gypsum Partition Board

-

Matt Glaze for Wall Tiles

Matt Glaze for Wall Tiles

-

Sunken Printing Glaze Powder

Sunken Printing Glaze Powder

-

Cargo Truck

Cargo Truck

-

4×2 Canvas Covered Truck

4×2 Canvas Covered Truck

-

T12 Series Vehicle Gas Engine

T12 Series Vehicle Gas Engine

-

HW18505T Series Light Duty Auto Transmission

HW18505T Series Light Duty Auto Transmission

-

WT615 Series Vehicle Gas Engine

WT615 Series Vehicle Gas Engine

-

WD415 Series Generator Set Diesel Engine

WD415 Series Generator Set Diesel Engine