Inkjet Printing Frit

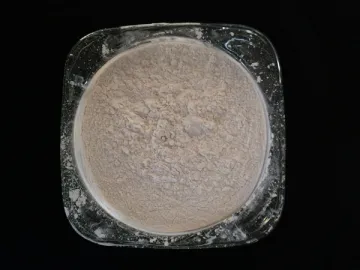

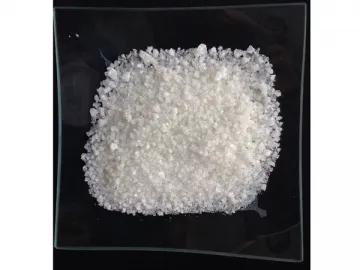

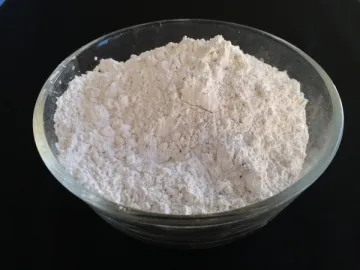

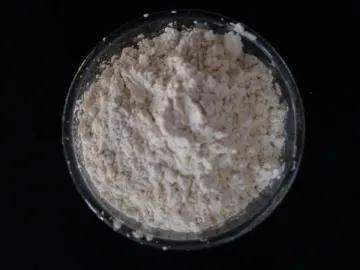

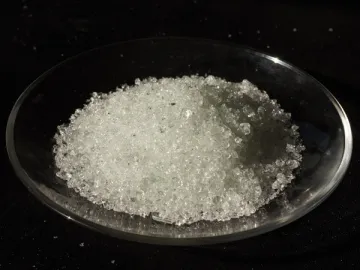

The WF-96 series of inkjet printing frit adopts the feldspar, quartz, dolomite, zirconium silicate, zinc oxide, etc. as the raw materials which are mixed and then put into the frit furnace to go through the process with the high temperature of 1550℃ to 1600℃ and the heat preservation treatment for up to 24 hours. It appears to be the transparent granular vitreous solid. The product is fit for cover glaze of the inkjet printing wall tile. It is produced with the inkjet special type and zirconium white inkjet type.

| Model | Expansion Coefficient (×10-7/℃ ) | Softening Point(℃) | Firing Temperature (℃) |

| WF-962 | 185-195 | 750 | 1080-1120 |

| WF-966 | 180-185 | 750 | 1100-1130 |

Features

1. The inkjet printing frit has high colorace ability. Compared with common product, it can save use cost and the ink by more than 30%.

2. The color won't diffuse. The inkjet printing effect can be shown fully.

3. By using the product, the glaze layer is ultra flat and glossy. Its surface glossiness is higher than 95 degrees. Meanwhile, the glaze layer has no pinhole and fewer ripples.

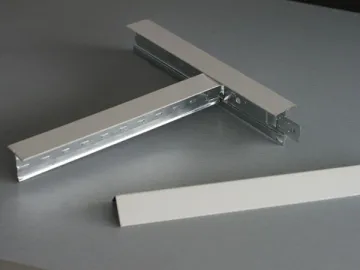

As a China-based inkjet printing frit manufacturer and supplier, we also provide ceramic opaque frit, crystal polished glaze for wall tile, ceramic body stain, aluminum plastic ceiling panel, and more.

Links:https://www.globefindpro.com/products/84585.html