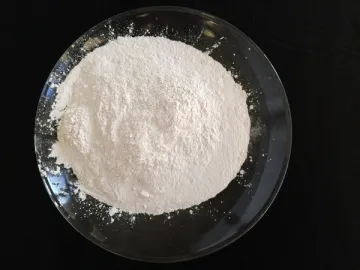

Lead/Boron Frit

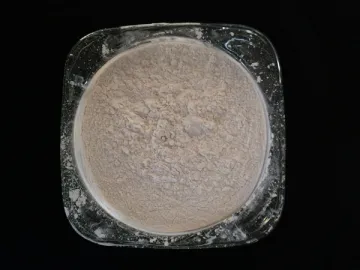

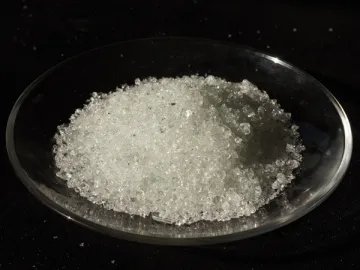

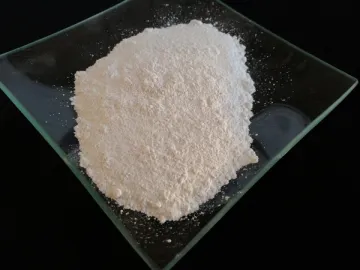

Using the oxide of lead and boron as the solvent, the lead and boron frit is produced through sintering with the temperature of 1400℃ to 1450℃. It appears to be the milk white granular vitreous solid.

The product has comparatively low firing temperature. It is fit for low temperature sintered ceramic tile, terra cotta, dolomite porcelain or artistic porcelain. By reason of containing the lead and boron elements, the product has high glossiness and transparency with relatively large expansion coefficient. It can be applied for a variety of ceramic body and can strengthen the coloring effort of the pigmented glaze.

| Model | Description |

| WF-9451 | High transparency, high glossiness, high lead content (≥30%), pure colorace |

| WF-9452 | High transparency, high glossiness, high lead content (≥50%), pure coloring effort, lower using temperature |

| Model | Expansion Coefficient (×10 -7 /℃ ) | Softening Point (℃) | Firing Temperature (℃) |

| WF-9451 | 205 | 690 | 920-1000 |

| WF-9452 | 230 | 580 | 850-950 |

This series of lead and boron frit is produced into two types with the models of WF-9451 and WF-9452 respectively. Its firing temperature is between 900℃ and 1000℃ and the softening point can be low to 600℃. The product can fully satisfy the common application demands.

As a specialized lead/boron frit manufacturer and supplier in China, our company also provides water glass (sodium silicate), crystal polished glaze for wall tile, ceramic wall tile, and seal tape, among others.

Related Names:

Safe Raw Material | Frit for Roof Tile

Links:https://www.globefindpro.com/products/84588.html