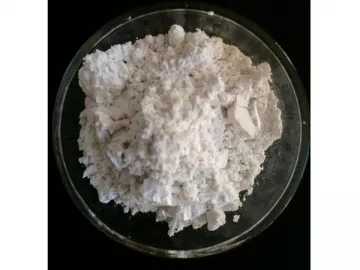

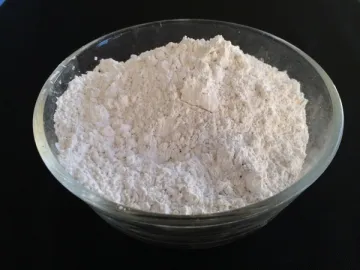

Opaque Printing Glaze

The opaque printing glaze adopts high quality raw materials. It is produced through the processes containing mixing, wet grinding, sieving, iron removal, drying, pulverizing, sorting, etc. The finished product is the white powder. It is mainly employed for silk screen printing and rubber roller printing of the ceramic wall tile and floor tile.

Technical Parameters| Model | Using temperature (℃) | Description |

| P-7110 | 1100-1130 | The product is suitable for single and double firing wall tiles. |

| P-7114 | 1140-1180 | It is fit for ordinary printing floor tiles. |

| P-7110A | 1080-1130 | Featuring ultra high whiteness, the product is applicable for wall tiles. |

Our opaque printing glaze has three types with the models of P-7110, P-7114 and P-7110A. Its using temperature ranges from 1080℃ to 1180℃. The features of the product cover good opacifying effect, high whiteness, high surface quality and wide firing range. The fineness of the product used for silk screen printing and rubber roller printing is no less than 325 meshes and no less than 500 meshes respectively. The screen residue of the three products is the same of no greater than 0.1%.

As a specialized opaque printing glaze manufacturer and supplier in China, we also provide waterproof engobe, solid sodium silicate (water glass), lead/boron frit, paper faced gypsum partition board, and much more.

Related Names:

Zirconium White Printing Glaze | Non-Transparent Glaze

Links:https://www.globefindpro.com/products/84612.html

-

Glazed Polish Floor Tile

Glazed Polish Floor Tile

-

Ceramic Carpet

Ceramic Carpet

-

Ingersoll Rand Screw Air Compressor Replacement Parts, Air Filters

Ingersoll Rand Screw Air Compressor Replacement Parts, Air Filters

-

Composed Glaze for Homogeneous Tile

Composed Glaze for Homogeneous Tile

-

Sullair Screw Air Compressor Replacement Parts, Air Filters

Sullair Screw Air Compressor Replacement Parts, Air Filters

-

Opaque Ceramic Tile Glaze

Opaque Ceramic Tile Glaze

-

Solid Sodium Silicate (Water Glass)

Solid Sodium Silicate (Water Glass)

-

Waterproof Engobe

Waterproof Engobe

-

Atlas Copco Screw Air Compressor Replacement Parts, Air oil Separator

Atlas Copco Screw Air Compressor Replacement Parts, Air oil Separator

-

Crystal Polished Glaze for Wall Tile

Crystal Polished Glaze for Wall Tile

-

Pigment for Glaze

Pigment for Glaze

-

Printing Glaze for Rotocolor

Printing Glaze for Rotocolor