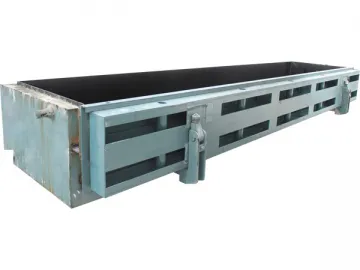

A2 Block Moulding Machine

The block moulding machine is developed to make perforated bricks and standard bricks. Three oil jacks are installed to the up part of the main frame. The middle oil jack is mainly used for pressing, and two other ones are utilized for mould lifting and auxiliary pressuring. In addition, our machine applies two motors to drive the vibration cabinet. Under such condition, the oil jack will send the plate automatically, and the bricks will be discharged via the conveyor belt. Through combining the vibration with the oil jack, the machine features high efficiency. With the 360° material distribution that can be finished in one time, it can make the bricks of high compactness.

Mould Features

This machine uses the mould that has gone through the carburizing heat treatment. This type of mould comes with long lifespan, good abrasion resistance. When pressed, it has no breakage. Even after having been used to make 4,000,000 pieces of standard bricks, the mould has no deformation. It remains the same within 6 to 8 months or so.

Parameters

| Mainframe Size | 2800x1800x2550 | Power | 19.2KW |

| Molding Area | 400x800mm | Exciting Force | 40KN |

| Molding Cycle | 15-25S | Blender Model | JQ500 |

| Supporting Plate Size | 1010x550x20/25mm | Water Consumption | 4T/day |

| Weight | 6.6T | Project Area | 150㎡ |

Theoretical Yield

| Size (L*W*H) (mm) | Pcs/mould | Pcs/h | Pcs/8h |

| 400x100x200 2 | 8 | 1440-1680 | 11520 |

| 400x150x200 3 | 6 | 1080 | 8640 |

| 400x200x200 4 | 4 | 720 | 5760 |

| 400x250x200 5 | 3 | 540 | 4320 |

| 230x110x70 6 | 24 | 4320 | 34560 |

| Paver:200x100x60 7 | 16 | 2880 | 23040 |

| Paver:200x163x60 8 | 8 | 1440 | 11520 |

Related Names

Brick Machine Manufacturer | Concrete Block Forming Device | Concrete Masonry Unit Equipment

Links:https://www.globefindpro.com/products/84656.html

-

DME Fractionating Column

DME Fractionating Column

-

Concrete Mould

Concrete Mould

-

B4 Block Moulding Machine

B4 Block Moulding Machine

-

B3 Block Moulding Machine

B3 Block Moulding Machine

-

Methanol Recovery Tower

Methanol Recovery Tower

-

Compair Screw Air Compressor Replacement Parts, Oil Filters

Compair Screw Air Compressor Replacement Parts, Oil Filters

-

Belt Conveyor

Belt Conveyor

-

Fusheng Screw Air Compressor Replacement Parts, Oil Filters

Fusheng Screw Air Compressor Replacement Parts, Oil Filters

-

Kobelco Screw Air Compressor Replacement Parts, Air Oil Separator

Kobelco Screw Air Compressor Replacement Parts, Air Oil Separator

-

A1 Block Moulding Machine

A1 Block Moulding Machine

-

B1 Block Moulding Machine

B1 Block Moulding Machine

-

Horizontal Double-Shaft Mixer

Horizontal Double-Shaft Mixer