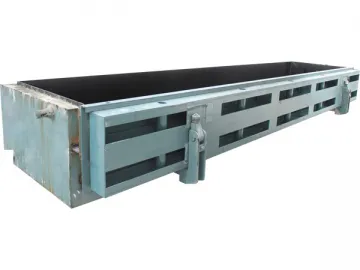

B3 Block Moulding Machine

Main Features

1. The vibrating case of the block moulding machine has two 5.5KW motors, and the upper mould is equipped with one 3KW vibration motor.

2. Our machine works through combining the bottom die directional vibration and upper die pressure vibration.

3. It is easy to operate. Its mold is electrically pulled or pushed. Material feeding is carried out by electricity. And the material distribution is finished in one time.

4. It is labor-saving. In general, 4 to 5 people are needed. 2 persons are separately responsible for the blender and molding machine. Another 2 people are required for the finished product packing.

5. The equipment can produce the air bricks, perforated bricks, or solid bricks of numerous specifications.

Parameters

| Mainframe Size | 2060 ×1730 ×2580mm | Power | 13.4KW |

| Voltage | 380V/220V/415V | Exciting Force | 35.5KN |

| Molding Cycle | 24S | Blender Model | JQ350 |

| Supporting Plate Size | 850 ×550 ×30mm | Workshop Area | 60㎡ |

| Weight | 3T |

Theoretical Yield

| Size (L*W*H) (mm) | Pcs/mould | Pcs/h | Pcs/8h |

| 400x100x200 | 7 | 630-840 | 5040-6720 |

| 400x150x200 | 5 | 450-600 | 3600-4800 |

| 400x200x200 | 4 | 360-450 | 2880-3600 |

| 400x250x200 | 3 | 270-360 | 2160-2880 |

Related Names

Block Molding Machine Manufacturer | Concrete Brick Equipment | Building Material Production

Links:https://www.globefindpro.com/products/84660.html

-

Methanol Recovery Tower

Methanol Recovery Tower

-

Compair Screw Air Compressor Replacement Parts, Oil Filters

Compair Screw Air Compressor Replacement Parts, Oil Filters

-

Slaking Silo

Slaking Silo

-

Fusheng Screw Air Compressor Replacement Parts, Air Filters

Fusheng Screw Air Compressor Replacement Parts, Air Filters

-

Concrete Cutting Machine

Concrete Cutting Machine

-

Heat-exchanging Vessel ( Heat Exchanger)

Heat-exchanging Vessel ( Heat Exchanger)

-

B4 Block Moulding Machine

B4 Block Moulding Machine

-

Concrete Mould

Concrete Mould

-

DME Fractionating Column

DME Fractionating Column

-

A2 Block Moulding Machine

A2 Block Moulding Machine

-

Belt Conveyor

Belt Conveyor

-

Fusheng Screw Air Compressor Replacement Parts, Oil Filters

Fusheng Screw Air Compressor Replacement Parts, Oil Filters

WH6989 Stone Curing Agent for Marble Granite Sandstone Limstone (Stain Resistant Special Effect Type)

WH6989 Stone Curing Agent for Marble Granite Sandstone Limstone (Stain Resistant Special Effect Type)

WH6982 Concrete Mortar Waterproof Penetrant for Porous Construction Materials (Emulsion Enhancement Type)

WH6982 Concrete Mortar Waterproof Penetrant for Porous Construction Materials (Emulsion Enhancement Type)