HM-DA660 Automatic Book Cover Maker

Main Design Features and Functions

1. The HM-DA660 automatic book cover maker adopts a Panasonic color touch screen, supporting fault cause and position display, as well as parameter setting and adjustment. This makes equipment operation and maintenance very convenient. Also, the machine is available with variable frequency speed adjustment system, low voltage control systems of Schneider, Omron, SMC, and Siemens brands.

2. A timer for glue pre-heating is adopted.

3. The machine is equipped with a hydraulic shock absorption swing-arm system for paperboard positioning.

4. The supporting platforms for the paperboard and the cover paper are both micro adjustable, so as to assure accurate operations. Additionally, the machine has cover paper platform auto positioning and position-correction function, as well as the book spine auto feeding and cutting function.

5. Japanese THK balls bearings and other famous brand components are adopted.

6. A safety shield is adopted to ensure the safety of operators.

7. The automatic book cover maker can be optionally equipped with devices to make round-cornered book covers.

8. It supports production of book covers with customized style.

9. As compared with conventional equipment, this book cover making machine has additional lining paper pasting function, which ensures improved working efficiency as well.

In addition to varied book covers, this hard cover making machine is also ideal for making the covers for the desk calendar, photo album, CD, and more.

Technical Parameters

| Unfolded book cover max. size | 660*405mm |

| Unfolded book cover min. size | 150*110mm |

| Gutter width | 3-12mm |

| Edge-folding width | 10-15mm |

| Paperboard thickness | 1-4mm |

| Sponge matted paperboard thickness | 1-6mm |

| Book spine width | 7-80mm |

| Production speed | 10-30pcs/min |

| Power | 11.5kw |

| Net weight | 5600kg |

| Equipment dimension | 3500*3500*1900mm |

Packaging Details

| Model | Wooden case | Length (m) | Width (m) | Height (m) | Total CBM | Net weight (kg) | Gross weight ((kg) | Total Weight (kg) |

| HM-DA660 | 5 | 1.59 | 1.38 | 1.44 | 18.62 | 900 | 1000 | 5380 |

| 1.59 | 1.60 | 1.68 | 900 | 1000 | ||||

| 1.60 | 1.24 | 0.92 | 600 | 530 | ||||

| 2.90 | 1.66 | 1.86 | 3000 | 2700 | ||||

| 1.50 | 0.49 | 0.56 | 200 | 150 |

Main Construction

Our automatic book cover maker mainly consists of the cover paper feeding and gluing, paperboard feeding and positioning, as well as the edge folding mechanisms.

1. The cover paper feeding and gluing system is equipped with a feeder to send the printed cover paper for gluing, and then deliver the glued paper to a conveyor belt to be bonded with the paperboard. Behind the feeder, there is a detector to avoid synchronous feeding of two pieces of paper caused by improper temperature and humidity conditions. The glue circulating pump originally imported from Japan offers reliable performance and ensures convenient glue quantity adjustment.

2. The paperboard feeding and positioning system is able to detect whether there is cover paper on the conveyor belt. When there is, it starts working, and intelligently adjusts the paperboard position via a PLC control system, thus ensuring accurate bonding between the cover paper and the paperboard. After this, the bonded material will be delivered to the four-edge folding-in system. Due to adoption of the Germany photosensitive elements, Japan’s Panasonic PLC and servo control system, and imported hydraulic drive system, the system offers accurate and fast operations.

3. The four-edge folding system firstly finish left and right side edge folding, and then the four corner pressing, and finally the upper and bottom edge folding. The imported photosensitive element for cam gear mechanism control ensures synchronous and stable four-corner pressing performance. Mechanical folding ensures elegant appearance for all end products. Pressing rollers are coated with water resistant Teflon material, which ensures not only easy cleaning and improved working efficiency, but also neat and clean surface for the end products.

Our automatic book cover maker offers high production capacity. Operated by 2 to 3 operators, the machine offers effective production capacity of 15-30pcs/min. Hence, the daily production capacity is up to 7000-15000 pieces, if the working time is 8 hours a day.

Hongming is an experienced automatic case maker manufacturer and supplier in China. In addition to hard cover making machine, we also offer box notching machine, gluing machine, rigid box making machine, and more.

Related Names

Book Cover Equipment | Hard Paper Board Machine | Book Surface Protection Sheet

Links:https://www.globefindpro.com/products/84706.html

-

HM-420 Rigid Box Folding-in Machine

HM-420 Rigid Box Folding-in Machine

-

HM-S240 Automatic Box Corner Pasting Machine

HM-S240 Automatic Box Corner Pasting Machine

-

DPP-250G Blister Packing Machine

DPP-250G Blister Packing Machine

-

HM-YP300B Box Pressing Machine

HM-YP300B Box Pressing Machine

-

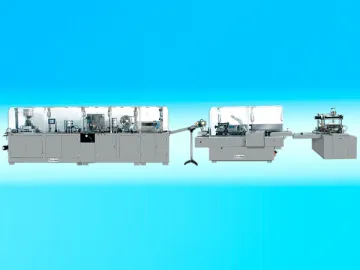

DCT-250 Blister Packing and Cartoning Line

DCT-250 Blister Packing and Cartoning Line

-

HM-1200C Automatic Grooving Machine

HM-1200C Automatic Grooving Machine

-

HM-1200B Grooving Machine

HM-1200B Grooving Machine

-

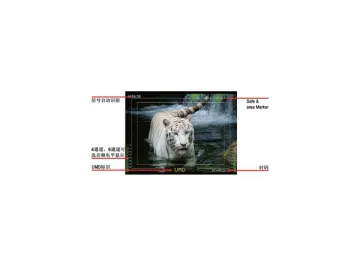

Audio/Video Test Signal Generator

Audio/Video Test Signal Generator

-

DCT-250P Blister Packing and Cartoning Line

DCT-250P Blister Packing and Cartoning Line

-

8 Inch Broadcast LCD Monitor

8 Inch Broadcast LCD Monitor

-

DPR-250 Blister Packing Machine

DPR-250 Blister Packing Machine

-

Video Converter

Video Converter