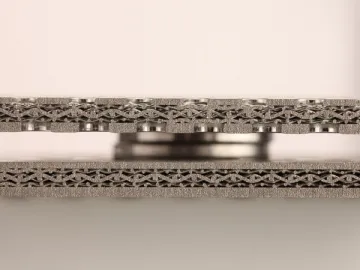

Sintered Cylinder Filter

This range of sintered cylinder filter is constructed using multi-layered sintered wire mesh. Firstly, the multi layers of wire mesh are overlapped together before they are sintered in a vacuum sintering furnace. Then, the sintered wire mesh is rolled into a cylinder with components for the two ends welded together.

The raw materials for the steel wire mesh include options such as SUS304 (AISI304), SUS316 (AISI316), and SUS316L(AISI316L). To meet individual demands, we can also manufacture products made using alloy steel materials including We can also produce the sintered filter element made using special alloy materials such as the hastelloy, monel, Inconel, and more.

In addition to liquid and gas filtering, the cylinder filter has also found applications in fields such as the petroleum, polyester, pharmacy, chemical fiber, food and beverage, water treatment, etc.

Features

1. Due to high mechanical strength, our sintered cylinder filter offers stable filtering performance even under high pressure conditions.

2. It is easy for cleaning, and is especially convenient for backwashing. Also, it is resistant to corrosion and high temperatures.

3. The product supports a wide filtering fineness range, from 1μm to 250μm.

4. We can offer products with outer diameter of10mmbut filtering fineness of 1μm.

5. A wide variety of connection methods are supported, including Double open end (DOE), single open end (SOE), thread connection, flange connection and lever connection methods.

6. Available gasket materials include the Buna-N, Viton, EPDM, and silicon rubber.

Technical advantages

From raw material quality inspection to sintered filter performance testing, we operate in strict conformation with the standards required by our senior engineers. This experienced engineering team also allows us to implement independent product designs and CAD drawing.

Quality Advantages

We use a series of advanced equipment for material and end product quality testing. Firstly, imported alloy analyzers are adopted for raw material specifications analysis, thus ensuring incoming material quality. Meanwhile, during each production process, the operation procedures are recorded and filed in computers for traceability. In the finished product testing stage, various advanced testing instruments including corrosion testing equipment and tensile testing equipment are utilized.

Packaging Advantages

The sintered cylinder filters are firstly packaged by bubble wrap to avoid deformation and damage during transportation, and then packaged in fumigation-free wooden cases. According to the order quality, the wooden case legs can be adjusted to an optimized height to ensure easy handling by forklift trucks.

Customer Service Advantages

With a complete after sales service system, we can record the goods delivery information timely, reply customers’ emails instantly, call back to buyers to get user feedbacks, and offer supports to users who have problems during use. We also make efforts to improve on our products and services based on customer feedbacks.

Related Names

Cylindrical Sintered Filters | Chemical Filtration Media | Swimming Pool Filter Cartridge

Links:https://www.globefindpro.com/products/84768.html

-

Big Bag Packing Machine

Big Bag Packing Machine

-

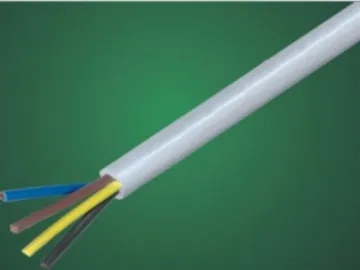

4 Core Flexible Power Cable

4 Core Flexible Power Cable

-

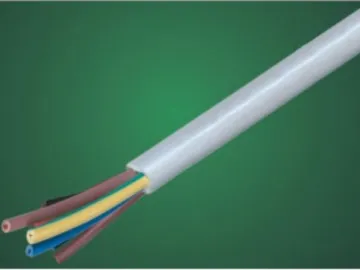

5 Core PVC Insulated Flexible Power Cable

5 Core PVC Insulated Flexible Power Cable

-

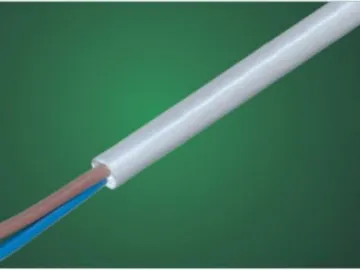

2 Core Power Cable/ Flexible Wire

2 Core Power Cable/ Flexible Wire

-

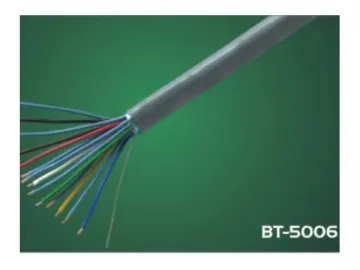

12 Pair Telephone Cable

12 Pair Telephone Cable

-

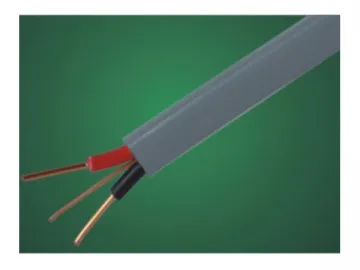

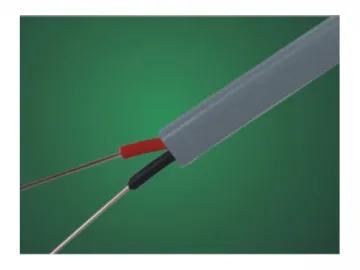

PVC Insulated Flat Power Cable with ECC

PVC Insulated Flat Power Cable with ECC

-

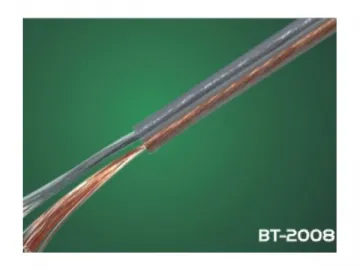

Golden and Silver Speaker Wire

Golden and Silver Speaker Wire

-

PVC Sheathed Flat Power Cable

PVC Sheathed Flat Power Cable

-

Shoe Box

Shoe Box

-

Sintered Wire Mesh with Perforated Metal

Sintered Wire Mesh with Perforated Metal

-

HM-950 Cover Pressing Machine

HM-950 Cover Pressing Machine

-

Sintered Filter for Centrifugal Separation

Sintered Filter for Centrifugal Separation