Automated Ultrasonic Welding System (for Card Production), WT-007DWJ

Automated ultrasonic welding system is PLC controlled, capable of providing accurate spot welding time and excellent welding result. This ultrasonic spot welder allows card sheets to be automatically loaded, distributed and arranged in an orderly manner, it is primarily applied in manufacturing various cards consisting of multilayer substrates.

Specifications

| Power supply | AC 380V/50 HZ | Format | 3X8/4X8/5X5/5X6 optional |

| Total power | 2.5KW | Control | PLC control servo system |

| Air source | 6 kg/cm2 | Operators needed | 1 |

| Air consumption | Approx. 100L/min | Dimension | L2350*W1250*H1700MM |

| Positioning accuracy | ±0.2mm | Welding thickness | 0.3mm~1.0mm |

| Weight | Approx. 1000KG | Quantity of welded spots | 1/2 |

| Applicable card materials | Paper card, PVC, ABS, PET, PVC/ABS composite materials, etc. | Productivity | 1200~1500 Sheet/H |

Productivity: 1200~1500 Sheet/H

Applicable card materials: Paper card, PVC, ABS, PET, PVC/ABS composite materials, etc.

Format: 3X8/4X8/5X5/5X6 optional

Positioning accuracy:±0.2mm

Welding thickness: 0.3mm~1.0mm

Quantity of welded spots: 1/2

Operators needed: 1

Power supply: AC 380V/50 HZ

Total power: 2.5KW

Control: PLC control servo system

Air source: 6 kg/cm2

Air consumption: Approx. 100L/min

Dimension: L2350*W1250*H1700MM

Weight: Approx. 1000KG Features Servo motor driven belt allows sheets to be precisely fed, transporting speed is adjustable; Adopting ultrasonic welding process provides durable and excellent welding result; Stable sheet feeding without scratching; Details Spot welding unit

Sheet loading unit

Sheet feeding unit

Scan QR to Read

Links:https://www.globefindpro.com/products/8481.html

Links:https://www.globefindpro.com/products/8481.html

Recommended Products

-

SIM Card Punching Machine, WT-007SCPM

SIM Card Punching Machine, WT-007SCPM

-

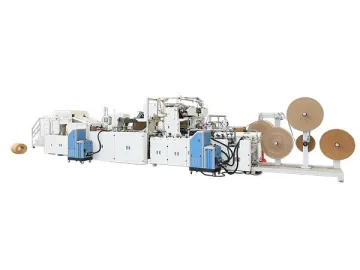

Automatic Bag Making Machine for Twisted Handles Paper Bag and Flat Handles Paper Bag

Automatic Bag Making Machine for Twisted Handles Paper Bag and Flat Handles Paper Bag

-

4 Channel 1296p Wireless Surveillance System with Android/iOS App, Wireless Security System, CM795755

4 Channel 1296p Wireless Surveillance System with Android/iOS App, Wireless Security System, CM795755

-

Sheet Cleaning Machine, WT-007ZCJ

Sheet Cleaning Machine, WT-007ZCJ

-

Corrugated Gas Connector Hose

Corrugated Gas Connector Hose

-

Automatic Card Punching and Sorting Machine (Paper/Plastic Card), WT-008CQFJ

Automatic Card Punching and Sorting Machine (Paper/Plastic Card), WT-008CQFJ

-

Fiberized Slurry Seal Equipment (13m³)

Fiberized Slurry Seal Equipment (13m³)

-

5000 liters Asphalt Emulsion Sprayer Truck Asphalt Distributor

5000 liters Asphalt Emulsion Sprayer Truck Asphalt Distributor

-

Road Maintenance Truck with Asphalt Heater

Road Maintenance Truck with Asphalt Heater

-

Asphalt Distributor Truck and Trailer

Asphalt Distributor Truck and Trailer

-

8000 liters Asphalt Emulsion Sprayer Truck Asphalt Distributor

8000 liters Asphalt Emulsion Sprayer Truck Asphalt Distributor

-

Chip Spreader Truck Asphalt Distributor, Chip Sealer 53 Type

Chip Spreader Truck Asphalt Distributor, Chip Sealer 53 Type

Hot Products