HM-ZD600 Automatic Rigid Box Making Machine

The HM-ZD600 automatic rigid box making machine is able to apply an even, thin coat of glue to the paper, which helps save glue. Thanks to the rapid tool change system, the die cutting device can be easily reconfigured to adapt to all types of processing, which reduces machine downtime and expedites production. The box grasper is constructed of the rail along with the slider, featuring great wear resistance and high operating stability. To ensure a proper feed rate at which the box is sent to the production line, the wrapping unit is supplied with a feed rate controller. The whole box making process is carried out automatically. This greatly improves production efficiency as well as reduces labor cost.

With stable performance, the rigid box making machine is well sold to customers, which attests to its popularity in the market. Its function has been extended to accommodate the complicated processing schemes, such as to make boxes into unusual shapes, produce unique cards (such as golden or silver card), or create boxes by using special raw material (such as the medium density fiberboard.). Its resulting box is durable and aesthetically appealing. For detailed information related to the construction of the machine as well as its electronic components, we welcome you to come to visit our company and factories.

Additionally, the machine is able to produce a variety of setup boxes, each of which includes both the box lid and base box, ready to fill items like shoe, cell phone, shirt, garment, gift, jewelry, chocolate, hardware, electronic product, and high-end food.

Specification

| Automatic rigid box making machine | HM-ZD600 | |

| Paper Sheet Size(B=Length, A=Width) | A ( max.) | 610mm |

| A ( min.) | 95mm | |

| B ( max.) | 850mm | |

| B ( min.) | 180mm | |

| Finish product (Box )SizeL=Length W=WidthH=Height T=Thickness | L ( max.) | 600mm |

| L ( min.) | 125mm | |

| W ( max.) | 400mm | |

| W ( min.) | 50mm | |

| H ( max.) | 130mm | |

| H ( min.) | 12mm | |

| Cardboard thickness (T) | T ( max.) | 3mm |

| T ( min.) | 1.0mm | |

| Thickness of Paper(m2/g) | 80g-160g/m2 | |

| Folding Edge size ( R ) | 10mm-20mm | |

| Speed | 20-35pcs/min | |

| Power | 17KW | |

| Net Weight | 5800kg | |

| Machine Dimension | 6800x4500x3300mm | |

Note:

1. The max. size and the min. size of box are determined by the max. and min. size of cover paper.

A( Min.)≤W 2H 2T 2R≤A(Max.); B( Min.)≤L 2H 2T 2R≤B(Max.)

2. The production speed of the rigid box maker is determined by the box size, paper and cardboard materials.

3. Customizable folded edge is 45mm

4. We don't provide air compressor. (8 atm=0.808MPA, 7.5KW compressor is needed)

Features

1. Just as the name suggests, our automatic rigid box making machine is an ideal fit for creating various kinds of rigid boxes in an automatic fashion.

2. The computer control system can automatically display machine malfunction and error to the users.

3. The wrapping paper and cardboard are automatically fed into the production line.

4. The machine features 24 hours control of glue pre-heating.

5. The cardboard is cut so as to bend up four sides of the base box. Then hot melt adhesive is automatically delivered and applied to the base box for binding its four corners together. These processes are carried out in one step.

6. Beneath the conveyor belt, there is an exhaust fan that creates vacuum to hold the wrapping paper tightly onto the conveyor, in order to prevent the paper deviating from the transfer course.

7. Semi-finished base boxes are collected at the wrapping machine, where the wrapping paper is pressed around the four sides of the box and flaps are folded. These processes are also completed in one step.

8. The base box needs to be placed on top and in the center of the glued paper. This process employs the hydraulic pneumatic spotter with a positioning precision of ±0.2mm.

9. The PLC system, photoelectric sensor, and the friendly human-machine interface with touch screen ensure the box forming process is done easily and quickly.

10. This series of rigid box making machine can automatically diagnose the machine failures, and triggers the alarm accordingly.

11. Upon request, the machine can be reconfigured to adapt to various paper production process.

12. Automatic control system for glue viscosity ( optional).

Hongming is a specialized automatic rigid box making machine manufacturer and supplier in China. We offer a vast array of products, including rigid box corner pasting machine, cover pressing machine, automatic notching machine, automatic gluing machine, and more.

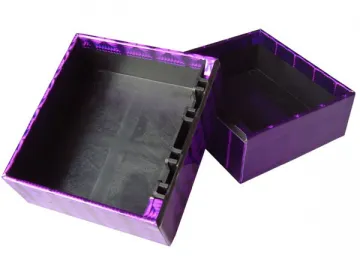

Finished Product Display

Related Names

Custom Rigid Carton Forming Device | Shoe Box Forming Equipment | Paper Gift Box Maker | Rigid Box Machine | Mobile Phone Box Machine | Rigid Box Making Machine | Box Machine

Links:https://www.globefindpro.com/products/84812.html

-

Granules Packing Machine

Granules Packing Machine

-

HM-ZD240 Automatic Rigid Box Maker

HM-ZD240 Automatic Rigid Box Maker

-

HM-BD240 Automatic Plastic Box Making Machine

HM-BD240 Automatic Plastic Box Making Machine

-

Four-side Sealing and Packing Machine

Four-side Sealing and Packing Machine

-

Mobile Phone Box

Mobile Phone Box

-

HM-650A Automatic Gluing Machine

HM-650A Automatic Gluing Machine

-

Corn Flakes Processing Line

Corn Flakes Processing Line

-

Cereal Bar Forming Machine

Cereal Bar Forming Machine

-

Cereal Flaking Machine

Cereal Flaking Machine

-

HM-650B Automatic Gluing Machine

HM-650B Automatic Gluing Machine

-

Continuous Fryer

Continuous Fryer

-

Twin Screw Food Extruder

Twin Screw Food Extruder