HM-ZD240 Automatic Rigid Box Maker

The HM-ZD 240 automatic rigid box maker adopts the graphic positioning system, which enables the wrapping paper and cardboard to be positioned at an extremely high precision level of ±0.05mm. It is applicable for making small-sized boxes to fill high-end jewelry, watch, pencil, gift, candy, souvenir, ornaments, and cosmetics. The machine is also adaptable to complicated manufacturing processes, such as to make irregular shaped boxes, unique paper cards, and plastic boxes. The minimum size of the resulting rigid box is 45mm×35mm×10mm.

For more information with respect to the machine construction and its electronic components, we encourage you to come to visit our company and factory.

Specification

| Wrapping Paper Size (B=Length, A=Width) | A (max.) | 305mm |

| A (min.) | 45mm | |

| B (max.) | 450mm | |

| B (min.) | 110mm | |

| Finished Product (Box)Size L=Length W=Width H=Height T=Thickness | L (max.) | 240mm |

| L (min.) | 45mm | |

| W (max.) | 160mm | |

| W (min.) | 35mm | |

| H (max.) | 80mm | |

| H (min.) | 10mm | |

| Cardboard Thickness (T) | T (max.) | 3mm |

| T (min.) | 0.5mm | |

| Thickness of Paper(g /m2) | 80g -160g /m2 | |

| Folding Edge size (R) | 8mm -20mm | |

| Speed | 18-30pcs/min | |

| Power | 13kw | |

| Net Weight | 3300kg | |

| Machine Dimension | 4500×4000×2600mm | |

Features

1. Our rigid box maker is able to bring out an impressive array of rigid boxes.

2. Machine fault or malfunction is automatically displayed thanks to the computer control system.

3. Automatic feed-in of the wrapping paper and cardboard.

4. Glue is pre-heated prior to being applied to the wrapping paper and cardboard. This pre-heating process is monitored for 24 hours by the control system.

5. The cardboard is cut to form four sides of the base box. Hot-melt glue automatically travels down and is applied to the four corners of the base box as well as the wrapping paper. All the processes are done in one step.

6. The exhaust fan sucks up enough air to hold the glued paper in place so as to avoid deviation from the conveyor track.

7. At the wrapping machine, the base boxes are collected and placed on top and in the center of the glued paper. Then the paper is pressed around the four sides of the base box and flaps are folded.

8. The spotter is fitted with Germany high-tech camera with 5 million pixels. Its spotting accuracy is ± 0.05mm.

9. The whole box making machine incorporates the PLC, photoelectric detector, and the friendly human-machine interface to ensure the box making process is completed independently

10. Machine failure is automatically diagnosed. Then the signal triggers the alarm to let the operator know.

11. If required, the machine can be reconfigured to accommodate various production processes.

12. Automatic control system for glue viscosity ( optional).

Note:

1. The maximum and minimum sizes of base box are determined by corresponding sizes of wrapping paper.

A( Min.)≤W 2H 2T 2R≤A(Max.) B( Min.)≤W 2H 2T 2R≤B(Max.)

2. The production speed of the rigid box maker is determined by the cardboard and wrapping paper materials as well as the size of base box.

3. We don't supply the air compressor. (A 0.606MPa, 5.5KW air compressor is needed)

As a professional automatic rigid box maker manufacturer and supplier in China, we also provide notching machine, rigid box folding-in machine, automatic case maker, semi-automatic box gluing machine, and more.

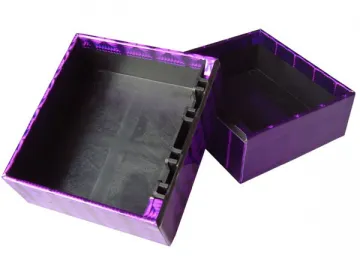

Finished Product Display

Related Names

Cell Phone Case Forming Device | Packaging Box Production Machine | Decorative Gift Box Maker | Paper Box Machine | Set up Box Machine | Box Making Machine | Cardboard Box Machine | Shoe Box Machine

Links:https://www.globefindpro.com/products/84814.html

-

HM-BD240 Automatic Plastic Box Making Machine

HM-BD240 Automatic Plastic Box Making Machine

-

Four-side Sealing and Packing Machine

Four-side Sealing and Packing Machine

-

Mobile Phone Box

Mobile Phone Box

-

HM-650A Automatic Gluing Machine

HM-650A Automatic Gluing Machine

-

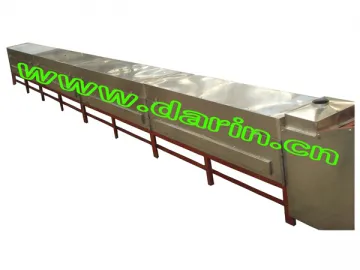

Noodle Boiling Machine

Noodle Boiling Machine

-

Noodle Pressing Machine

Noodle Pressing Machine

-

Granules Packing Machine

Granules Packing Machine

-

HM-ZD600 Automatic Rigid Box Making Machine

HM-ZD600 Automatic Rigid Box Making Machine

-

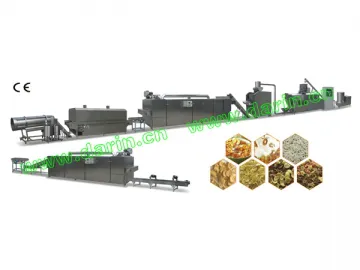

Corn Flakes Processing Line

Corn Flakes Processing Line

-

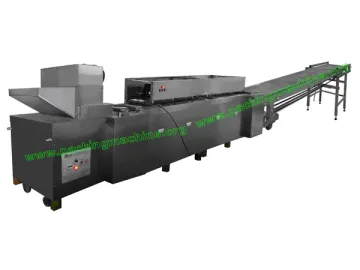

Cereal Bar Forming Machine

Cereal Bar Forming Machine

-

Cereal Flaking Machine

Cereal Flaking Machine

-

HM-650B Automatic Gluing Machine

HM-650B Automatic Gluing Machine