HM-BD240 Automatic Plastic Box Making Machine

As the title indicates, the HM-BD240 automatic plastic box making machine differs from the previous HM-ZD240 model in that the former proves more suitable for making plastic jewelry boxes than the latter. Additionally, it does not contain corner pasting unit, which means operators need to glue the four corners of the base box all by themselves and after that they have to put the semi-finished boxes back onto the belt for further processing.

For the purpose of positioning the base box precisely on top and in the center of the glued paper, the machine employs a spotter with a positioning accuracy of ±0.05mm. In addition to manufacturing plastic box, the machine is also capable of making irregular-shaped boxes, unique paper cards, and many small-sized, high-end boxes to fill jewelry, watch, pencil, gift, sweets, souvenir, ornament, and the cosmetic. The minimum box size is 45mm×35mm×10mm.

For more details related to the construction of the machine and its electronic components, we would like you to pay a visit to our company and factory.

Specification

| Automatic plastic box making machine | HM-BD240 | |

| Paper Sheet Size(B=Length, A=Width) | A ( max.) | 305mm |

| A ( min.) | 45mm | |

| B ( max.) | 450mm | |

| B ( min.) | 110mm | |

| Finish product (Box )SizeL=LengthW=WidthH=Height T=Thickness | L ( max.) | 240mm |

| L ( min.) | 45mm | |

| W ( max.) | 160mm | |

| W ( min.) | 35mm | |

| H ( max.) | 80mm | |

| H ( min.) | 10mm | |

| Cardboard thickness (T) | T ( max.) | 3mm |

| T ( min.) | 0.5mm | |

| Thickness of Paper(m2/g) | 80g-160g/m2 | |

| Folding Edge size ( R ) | 8mm-20mm | |

| Speed | 18-30pcs/min | |

| Power | 13KW | |

| Net Weight | 3300kg | |

| Machine Dimension | 4500x4000x2600mm | |

Note:

1. The max. size and the min. size of box are determined by the max. and min. size of cover paper.

A( Min.)≤W 2H 2T 2R≤A(Max.) B( Min.)≤W 2H 2T 2R≤B(Max.)

2. The production speed of the rigid box maker is determined by the box size, paper and cardboard materials.

3. We don't provide air compressor. ( 6 atm=0.606mpa, 5.5KW compressor is needed)

Features

1. Our plastic box making machine can produce a variety of rigid boxes in an automatic manner.

2. The computer control system detects and displays the manufacturing error as well as machine malfunction.

3. The wrapping paper is automatically fed into the production line.

4. The glue pre-heating temperature is kept under control 24 hours.

5. The exhaust fan is fitted underneath the conveyor. It creates vacuum to hold the glued paper tightly onto the belt, in order to prevent the paper deviating from the set course.

6. Semi-finished base boxes are collected at the box-wrapping unit, where the glued paper is pressed around the four sides of the box and flaps are folded. This process can be completed in one step.

7. The spotter is equipped with a high-tech camera of 5 million pixels.

8. Also installed onto the machine are the PLC system, photoelectric detector, and the friendly human-machine interface with touch screen. These assemblies help ensure an automatic production process.

9. Manufacturing errors are diagnosed independently and the corresponding alarm will be triggered to send warning to users.

10. If required, the machine can be remodeled to accommodate diverse box production schemes.

11. Automatic control system for glue viscosity ( optional).

Hongming is a specialized automatic plastic box making machine manufacturer and supplier in China. We provide a wide range of products, including single side cover edge folding machine, notching machine, automatic box corner pasting machine, and more.

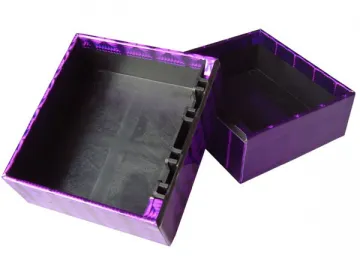

Finished Product Display

Related Names

Custom Plastic Case Maker | Hard Packaging Box Former | Gift Container Manufacture Device

Links:https://www.globefindpro.com/products/84815.html

-

Four-side Sealing and Packing Machine

Four-side Sealing and Packing Machine

-

Mobile Phone Box

Mobile Phone Box

-

HM-650A Automatic Gluing Machine

HM-650A Automatic Gluing Machine

-

Noodle Boiling Machine

Noodle Boiling Machine

-

Noodle Pressing Machine

Noodle Pressing Machine

-

Textile Box

Textile Box

-

HM-ZD240 Automatic Rigid Box Maker

HM-ZD240 Automatic Rigid Box Maker

-

Granules Packing Machine

Granules Packing Machine

-

HM-ZD600 Automatic Rigid Box Making Machine

HM-ZD600 Automatic Rigid Box Making Machine

-

Corn Flakes Processing Line

Corn Flakes Processing Line

-

Cereal Bar Forming Machine

Cereal Bar Forming Machine

-

Cereal Flaking Machine

Cereal Flaking Machine