XT-X Series Flexo Printer Slotter Die Cutter

The flexo printer slotter die cutter consists of a paperboard feeding system, four color flexographic printing machine, a paperboard slotting and creasing machine, as well as a rotary die cutting machine. It is a great solution for paper packaging material printing, slotting, and die cutting. It is especially popular in carton making industry.

Features

1. In order to ensure consistent reliable performance, this paper converting equipment employs international famous brand electrical elements and control software.

2. Through aging treatment and tempering treatment, the wall panel and other key components for the flexo printer slotter die cutter have high structural stability due to eliminated internal stress. The structural precision is also ensured, because of our adoption of high precision machining centers and CNC grinding machines.

3. All the shafts and rollers are fabricated using quality steel. They feature excellent surface quality and durability, due to treatments from tempering, thermal refining, surface grinding, precision dynamic balancing, to surface chrome plating.

4. All the transmission gears for the corrugated or cardboard box making equipment are made of 20CrMnTi alloy steel. Through carburizing and quenching, they are available with hardness from HRC58 to 62. After gear grinding, they offer very high precision which ensures superb color register precision of the four color printing equipment with slotting and die cutting function.

5. The four color flexo printer slotter die cutter utilizes expansion sleeve for the connection between shafts and gears, thus eliminating the connection gap. This makes the carton making machine ideal for continuous high speed operation.

6. Reinforced self-aligning bearing is employed as the drive bearing, and is also utilized for the key transmission parts. This ensures convenient maintenance and extended service life.

7. The spray lubrication system, coupled with oil level display unit, ensure long term smooth and safe operation of our flexo printer slotter die cutter. Additionally, the entire equipment set is designed with a special unit to ensure balanced oil level between the inlet and outlet oil tanks.

8. The gap among the feeding, printing, slotting, and die cutting units can be conveniently adjusted without using a spanner. This is because of the employment of self-locking worm gear mechanism.

9. The main functional units are variable frequency controlled, providing smooth and soft starting as well as reduced energy consumption.

10. Due to the user-friendly designed feeding unit, the four color flexo printer slotter die cutter is available with different paperboard feeding modes, including vacuum absorption, back-pushing, and roller feeding modes.

11. This printing slotting die cutting machine has automatic pre-register function. Via only one button, the computer control system allows all the printing plates to automatically move to the central line positions of paperboards. This function largely helps save cost due to the reduced paper waste during manual color register process.

12. Ceramic anilox is optional.

Main Technical Parameters

| Serial Number | Item | Unit | Parameters |

| 900×1800 (¢304) | |||

| 1 | Inner body width | mm | 2200 |

| 2 | Maximum feeding size (continuous feeding) | mm | 950×2000 |

| 3 | Maximum printing size | mm | 900×1800 |

| 4 | Maximum feeding size (feeding every other one) | mm | 1150×2000 |

| 5 | Minimum printing size | mm | 300×640 |

| 6 | Thickness of printing plate | mm | 6 |

| 7 | Wall panel thickness of machine | mm | 50 |

| 8 | Maximum speed | Pieces/Minute | 150 |

| 9 | Economic speed | Pieces/Minute | 120 |

| 10 | Color register precision | mm | 4 colors ±0.5 |

| 11 | Slotting precision | mm | ±1.5 |

| 12 | Maximum slotting depth | mm | 200 |

| 13 | Minimum slotting interval | mm | Clockwise: 160×160× 160×160 |

| 260×60×260×60 |

Links:https://www.globefindpro.com/products/84831.html

-

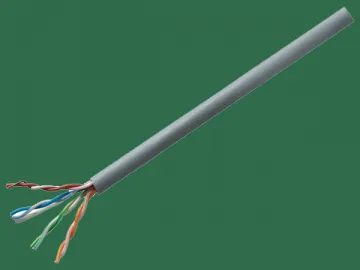

23AWG UTP CAT6e Bare Copper Network Cable

23AWG UTP CAT6e Bare Copper Network Cable

-

Four Head Slotting Machine

Four Head Slotting Machine

-

Semi Automatic Laminating Machine

Semi Automatic Laminating Machine

-

21 PCS Drill Bit Sets

21 PCS Drill Bit Sets

-

Equal Shank Drill Bit

Equal Shank Drill Bit

-

Paperboard Stacker

Paperboard Stacker

-

Food Coating Machine

Food Coating Machine

-

RG-6/U Coaxial Cable with Telephone Wire

RG-6/U Coaxial Cable with Telephone Wire

-

Continuous Pillow Packing Machine

Continuous Pillow Packing Machine

-

Powder Packing Machine

Powder Packing Machine

-

BJ Series Laminating Machine

BJ Series Laminating Machine

-

Horizontal Packing Machine

Horizontal Packing Machine