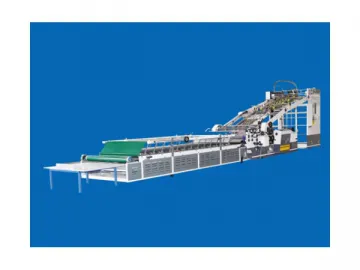

XT-L Series 3-Color Flexo Printer Slotter

The 3-color flexo printer slotter is composed of two units. One is the paper packaging material printing unit which supports three-color printing. The other is the slotting unit which is actually a rotary cutting and creasing machine combining paperboard cutting, grooving and creasing functions. The two units can also be used independently for paper converting in carton making industry.

Functions and Characteristics

1. The XT-L series 3-color flexo printer slotter is designed with a chain feeder for paperboard delivering. The feeder is connected with the three color printing machine via a clutch, which ensures accurate and convenient color register.

2. The cardboard box making machine adopts an electric system to control the detachment and combination between the printing and slotting units, a pneumatic system for locking of the two units, as well as pneumatic brakes to fix the position of the two units. These designs ensure high operation safety.

3. The three color flexo printer comes with a pneumatic lifting system for the printing plate, and an automatic ink distribution system to prevent ink drying.

4. Via a planetary gear mechanism, the rotation angle of both printing cylinder and cutter head are adjustable within the range of 360 degrees, and the angle can be digitally displayed to maximize convenience.

5. This range of 3 color flexo printer slotter is installed with a gear pump for automatic lubrication.

6. The ink roller and the printing press roller for the paper converting equipment are connected by a crosshead shoe so as to ensure a steady transmission.

7. All shafts and rollers are precision ground and hard chrome plated. This, coupled with famous brand electrical elements and apparatus, makes sure our 3-color flexo printer slotter has outstanding performance and high safety.

8. Quality HRB bearing is adopted to further enhance reliability.

9. The 3-color flexo printer slotter utilizes an optoelectronic counter to realize planned production by presetting of processing quantity.

Main Technical Parameters

| Serial Number | Item | Unit | Parameters | |||||

| 1030×1900 (¢360) | 1450×1900/2300/2700 (¢480) | 1700×2300/2700 (¢560) | ||||||

| 1 | Inner body width | mm | 2200 | 2200 | 2600 | 3000 | 2600 | 3000 |

| 2 | Maximum feeding size | mm | 1080×2000 | 1500×2100 | 1500×2500 | 1500×2900 | 1750×2500 | 1750×2900 |

| 3 | Minimum printing size | mm | 260×610 | 380×640 | 380×640 | 380×640 | 450×720 | 450×720 |

| 4 | Maximum printing size | mm | 1030×1900 | 1450×1900 | 1450×2300 | 1450×2700 | 1700×2300 | 1700×2700 |

| 5 | Thickness of printing plate | mm | 6 | 7.2 | 7.2 | |||

| 6 | Wall panel thickness of machine | mm | 50 | 36 | 36 | |||

| 7 | Maximum speed | Pieces/minute | 80 | 60 | 60 | |||

| 8 | Color register precision | mm | ±0.5 | ±0.5 | ±0.5 | |||

| 9 | Slotting precision | mm | ±1.5 | ±1.5 | ±1.5 | |||

| 10 | Maximum slotting depth | mm | 250 | 300 | 400 | |||

| 11 | Minimum slotting interval | mm | 205×60×205×60 | 260×60×260×60 | 280×80×280×80 | |||

Links:https://www.globefindpro.com/products/84839.html

-

Sheet Pressing Machine

Sheet Pressing Machine

-

Paperboard Cutting and Creasing Machine

Paperboard Cutting and Creasing Machine

-

SR-AFG 1500 Semi-auto Folder Gluer

SR-AFG 1500 Semi-auto Folder Gluer

-

Automatic Laminating Machine

Automatic Laminating Machine

-

Combined Rotary Creasing Slotting and Slitting Machine

Combined Rotary Creasing Slotting and Slitting Machine

-

Automatic Flatbed Die Cutting Machine

Automatic Flatbed Die Cutting Machine

-

Half Ground HSS Drill Bit

Half Ground HSS Drill Bit

-

Paperboard Stacker

Paperboard Stacker

-

Equal Shank Drill Bit

Equal Shank Drill Bit

-

21 PCS Drill Bit Sets

21 PCS Drill Bit Sets

-

Semi Automatic Laminating Machine

Semi Automatic Laminating Machine

-

Four Head Slotting Machine

Four Head Slotting Machine