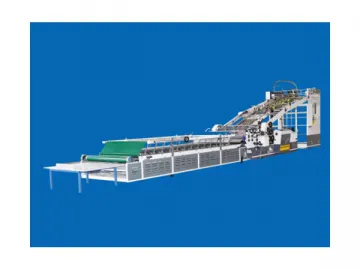

Automatic Laminating Machine

Our range of automatic laminating machine, sometimes called automatic flute laminator, is fit for lamination between cardboards, as well as lamination between cardboard and 3-5 ply corrugated board. It supports A, B, C, and D flute corrugated boards, and thus is widely used in corrugated box making industries.

Features

1. The automatic sheet to sheet laminating machine can realize automatic feeding of bottom and top sheets, so it features easy and fast operation, and helps reduce labor intensity. The vacuum suction style feeding unit makes the paper laminating system ideal for high-thickness paperboards.

2. With a special feeding material positioning unit, this sheet to sheet laminator effectively prevents bottom sheet from exceeding the top sheet. Also, it supports adjustment of the position of bottom and top sheets, thus ensuring accurate lamination.

3. The automatic laminating machine is available with an automatically controlled glue supply system. The innovative rubber roller and steel roller combination ensures uniform glue coating. Additionally, the gluing unit supports glue coating thickness adjustment and excessive glue recycling. These designs ensure minimized glue waste and maximized coating precision.

5. Balance test for glue coating rollers, secure assembly, plus the timing belt for driving enable the laminating and board mounting machine to operate with extremely low noise but high precision.

6. The operation speed of the sheet to sheet laminator is adjustable. The automatic laminating machine also uses a photoelectric detection system for stroke position control. Additionally, it is designed with an electronic counter to ensure accurate counting, and a photoelectric control unit to avoid lacking of sheets. These ensure very high lamination precision, and make sure end products have high surface smoothness and high strength as well.

7. The automatic flute laminator is manufactured under ISO9001 standard. Its key components such as the harmonic gear and bearings are imported, and the electrical components are acquired from national or international famous brands. These are some of the reasons why our paperboard lamination machine has low failure and stable performance.

Technical Parameters

| Items | Unit | BZJ-1300 | BZJ-1450 | BZJ-1600 |

| Maximum coverage size (W×L) | mm | 1300×1100 | 1450×11000 | 1600×11000 |

| Minimum coverage size (W×L) | mm | 350×350 | 350×350 | 350×350 |

| Lamination precision | mm | ≤±1.5 | ≤±1.50 | ≤±1.50 |

| Maximum mechanical speed | m/min | 100 | 100 | 100 |

| Total power | KW | 120 | 1 | 13 |

| Overall dimensions | m | 12.5×2.15×2.6 | 12.5×2.30×2.6 | 12.5×2.45×2.6 |

| Total weight | T | 6.8 | 7.2 | 8.0 |

Links:https://www.globefindpro.com/products/84845.html

-

Combined Rotary Creasing Slotting and Slitting Machine

Combined Rotary Creasing Slotting and Slitting Machine

-

Automatic Flatbed Die Cutting Machine

Automatic Flatbed Die Cutting Machine

-

Automatic Partition Slotting Machine

Automatic Partition Slotting Machine

-

Semi-Auto Box Stitching Machine

Semi-Auto Box Stitching Machine

-

XT-G Series Rotary Die Cutting Machine

XT-G Series Rotary Die Cutting Machine

-

Automatic Folder Gluer

Automatic Folder Gluer

-

SR-AFG 1500 Semi-auto Folder Gluer

SR-AFG 1500 Semi-auto Folder Gluer

-

Paperboard Cutting and Creasing Machine

Paperboard Cutting and Creasing Machine

-

Sheet Pressing Machine

Sheet Pressing Machine

-

XT-L Series 3-Color Flexo Printer Slotter

XT-L Series 3-Color Flexo Printer Slotter

-

Half Ground HSS Drill Bit

Half Ground HSS Drill Bit

-

Paperboard Stacker

Paperboard Stacker