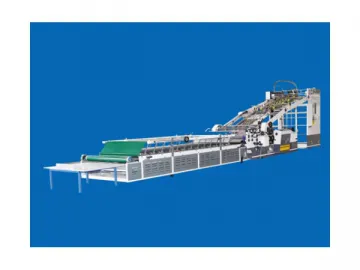

Combined Rotary Creasing Slotting and Slitting Machine

As its name indicates, the combined rotary creasing slotting and slitting machine combines the functions of the following machines: paper creasing machine, slotting machine, rotary slitting machine, and paperboard cutting machine. It is a kind of commonly used carton making machinery, due to its high working efficiency.

This range of corrugated box making machine is mainly made up of the following two units:

Feeding Unit

1. The combined rotary creasing slotting and slitting machine adopts a chain feeder for paperboard delivering. Stepless speed control ensures accurate and smooth feeding.

2. The elastic pressing plate at the front end of the feeding system allows for feeding of curled paperboards. This makes sure the paper converting equipment has low requirement on feeding material quality.

3. Due to the photoelectric counter, the machine supports presetting of the order quantity.

4. A clutch is utilized for the connection between the feeding platform and the cutting unit.

5. The frame is welded using C sections, and the surface plate is made using 3mm thick cold rolled steel plate.

6. The elastic pressing plate is made of cold drawn steel with diameter of 30mm, and its surface is chrome plated.

Paper Cutting Unit

1. The combined rotary creasing slotting and slitting machine is available with three groups of slotting tool, one group of corner cutting tool, two groups of slitting tool and four groups of creasing wheel.

2. The tool rest supports 360 degree mechanical adjustment of its rotation angle. An optional electric controlled unit for angle adjustment is also available.

3. Paperboard creasing system

(1) The shaft has diameter of 99mm, and its surface is precision polished and hard chrome plated.

(2) Dynamic balance is carried out to ensure stable operation.

(3) The distance between creasing wheels can be manually adjusted from 0 to 12mm.

4. Slotting system

(1) The ¢156mm shaft also undergoes precision grinding and hard chrome plating to ensure fine surface quality.

(2) The slotting knife width is 7mm.

(3) The slotting knives come with high hardness and tensile strength, due to the quality alloy steel material as well as heat treatment and grinding treatments.

5. The combined rotary creasing slotting and slitting machine also has trimming function. The trimming tool is made of superior quality alloy steel and undergoes heat treatment and precision grinding to ensure high precision performance.

6. The paper converting machine supports manual adjustment of the lateral movement of creasing wheel and slotting tool.

7. Our rotary creasing slotting and slitting machine can be optionally designed with die holders for creating handle holes on a carton.

(1) Upper die holder width: 100mm, lower die holder width: 100mm (a rubber mat is available)

(2) Size of handle hole: 90×25mm, or ¢30mm

Main Technical Parameters

| Parameters | Unit | Model | |

| 2200 | 2600 | ||

| Coverage size | mm | 1500×2100 | 1500×2500 |

| Minimum processing size (length × width) | mm | 380×500 | 380×500 |

| Processing speed | pieces/minute | 0-60 | 0-60 |

| Power of main motor | kW | 3 | 3 |

Links:https://www.globefindpro.com/products/84846.html

-

Automatic Flatbed Die Cutting Machine

Automatic Flatbed Die Cutting Machine

-

Automatic Partition Slotting Machine

Automatic Partition Slotting Machine

-

Semi-Auto Box Stitching Machine

Semi-Auto Box Stitching Machine

-

XT-G Series Rotary Die Cutting Machine

XT-G Series Rotary Die Cutting Machine

-

Automatic Folder Gluer

Automatic Folder Gluer

-

XT-D Series Rotary Cutting and Creasing Machine

XT-D Series Rotary Cutting and Creasing Machine

-

Automatic Laminating Machine

Automatic Laminating Machine

-

SR-AFG 1500 Semi-auto Folder Gluer

SR-AFG 1500 Semi-auto Folder Gluer

-

Paperboard Cutting and Creasing Machine

Paperboard Cutting and Creasing Machine

-

Sheet Pressing Machine

Sheet Pressing Machine

-

XT-L Series 3-Color Flexo Printer Slotter

XT-L Series 3-Color Flexo Printer Slotter

-

Half Ground HSS Drill Bit

Half Ground HSS Drill Bit