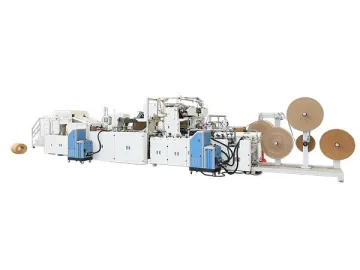

Automatic Card Punching and Sorting Machine (Paper/Plastic Card), WT-008CQFJ

This automatic card punching and sorting machine is particularly suitable for manufacturing name cards, membership cards and ID cards. Suction cup holds the uppermost sheet to ensure single sheet feeding each time, facilitating automated sheets feeding process while preventing double pieces feeding. Two stepper motors allow for accurate positioning and alignment of sheets, as well as automatic cards sorting and collecting.

Finished Products Key cards

Membership cards

Name cards

Specifications

| Power supply | AC 380V/50 HZ | Sheet format | 5X5/5X6/3X8/4X8 optional |

| Total power | 12KW | Control | PLC control servo/hydraulic system |

| Air source | 6 kg/cm2 | Operators needed | 1 |

| Air consumption | Approx. 150L/min | Dimension | L2800*W2750*H1700MM |

| Punching pressure | 2T-6T | Drive | Servo/hydraulic system |

| Weight | Approx. 1500KG | Punched card size | Standard size, such as name card, membership card |

| Punching accuracy | ±0.10mm | Productivity | 20000~55000PCS/H |

| Applicable card materials | Paper card, PVC, ABS, PET, PVC/ABS composite materials, etc. |

Productivity: 20000~55000PCS/H

Punched card size: Standard size, such as name card, membership card

Punching accuracy:±0.10mm

Sheet format: 5X5/5X6/3X8/4X8 optional

Punching pressure: 2T-6T

Control: PLC control servo/hydraulic system

Dimension: L2800*W2750*H1700MM

Weight: Approx. 1500KG

Power supply: AC 380V/50 HZ

Total power: 2KW

Air source: 6 kg/cm2

Operators needed: 1

Air consumption: Approx. 150L/min

Drive: Servo/hydraulic system

Applicable card materials: Paper card, PVC, ABS, PET, PVC/ABS composite materials, etc. Features

Sheet feeding unit

Sheets are stacked onto the tray, motor drives sheet tray to accomplish feeding process;

Alignment unit

Coupled with two stepper motors and photoelectric sensor, sheets are precisely positioned and aligned, providing high accuracy of sheet position;

Servo punching unit

High torque servo motor is adopted to guarantee stable work pressure and low noise level;

Automatic sorting unit

Vacuum suction cup transfers and distributes sheets into sorting lanes to accomplish card collection process, eliminating the need for manual sorting;

Links:https://www.globefindpro.com/products/8487.html

-

Automated Hole-punching and Creasing Machine, WT-007PCM

Automated Hole-punching and Creasing Machine, WT-007PCM

-

Slitter Rewinder

Slitter Rewinder

-

Rope Making Machine

Rope Making Machine

-

Flat and Satchel Bag Making Machine

Flat and Satchel Bag Making Machine

-

Digital Wireless Pan/Tilt Camera and 7” LCD Monitor System, CM531723

Digital Wireless Pan/Tilt Camera and 7” LCD Monitor System, CM531723

-

1080P Wireless Security Camera with LED Light, WF794

1080P Wireless Security Camera with LED Light, WF794

-

Corrugated Gas Connector Hose

Corrugated Gas Connector Hose

-

Sheet Cleaning Machine, WT-007ZCJ

Sheet Cleaning Machine, WT-007ZCJ

-

4 Channel 1296p Wireless Surveillance System with Android/iOS App, Wireless Security System, CM795755

4 Channel 1296p Wireless Surveillance System with Android/iOS App, Wireless Security System, CM795755

-

Automatic Bag Making Machine for Twisted Handles Paper Bag and Flat Handles Paper Bag

Automatic Bag Making Machine for Twisted Handles Paper Bag and Flat Handles Paper Bag

-

SIM Card Punching Machine, WT-007SCPM

SIM Card Punching Machine, WT-007SCPM

-

Automated Ultrasonic Welding System (for Card Production), WT-007DWJ

Automated Ultrasonic Welding System (for Card Production), WT-007DWJ