2 Layer PE Coated Steel Pipe

The 2 layer PE coated steel pipe is provided with two layers of coating. The first layer is the adhesive coating which bonds with the steel pipe, and the second layer is polyethylene coating. The thickness of each layer is the same as that of 3 layer PE coated steel pipe, i.e., the thickness of the adhesive layer and PE layer is 170 to 250 μm and 2.5 to 3.7 mm respectively.

Specification

| Material | Q235, Q345B, L245, L290, L360, L450, X42, X52, X60, X65, X70, X80 |

| Diameter | 15-1240 mm (SSAW / LSAW) |

| Length | 12m or Specified Length |

| Wall Thickness | 1-18 mm |

| Applicable Range | petroleum, chemical engineering, natural gas, hydraulic power plant, sewage disposal, bridge piling, steel structure pillar, etc. |

| Executive Standard | DIN30670, DIN30671, SY/T0413-2002, SY/T0315-97 |

Performance Index of Anticcorosion Coating

| No. | Item | Performance Index | Test Method | |

| Two Layers | Three Layers | |||

| 1 | Peeling Strength (N/cm) 20±5℃ 50±5℃ | ≥3.5 ≥2.5 | ≥60 ≥40 | DIN30670 |

| 2 | Cathodic Disbonding (mm) (60℃, 4h) | ≤15 | ≤10 | SY/T4013 |

| 3 | Impact Strength (J/mm) | ≥5 | DIN30670 | |

| 4 | Bending Resistance (2.5°) | No cracking of PE | SY/T4013 | |

| 5 | Pinhole Leak Detection (25KV) | No leakage | DIN30670 | |

Related Names

Corrosion Resistant Steel Tubing | Sewer Pipe | Drainage Pipe

Scan QR to Read

Links:https://www.globefindpro.com/products/84886.html

Links:https://www.globefindpro.com/products/84886.html

Recommended Products

-

Solar Laptop Battery Charger

Solar Laptop Battery Charger

-

API Steel Pipe

API Steel Pipe

-

Hot Rolled Seamless Steel Pipe

Hot Rolled Seamless Steel Pipe

-

ERW Steel Pipe (Electric Resistance Welding)

ERW Steel Pipe (Electric Resistance Welding)

-

Lincoln Air Suspension Parts

Lincoln Air Suspension Parts

-

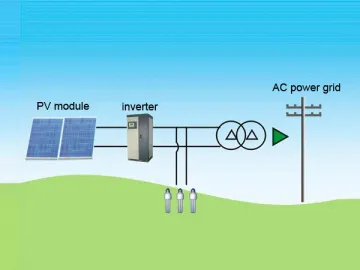

On Grid/Grid Tie Solar Power System

On Grid/Grid Tie Solar Power System

-

29 PCS Drill Bit Sets

29 PCS Drill Bit Sets

-

Monocrystalline Solar Panel

Monocrystalline Solar Panel

-

13 PCS Drill Bit Sets

13 PCS Drill Bit Sets

-

Land Rover Air Suspension Parts

Land Rover Air Suspension Parts

-

HDPE Coated Steel Pipe

HDPE Coated Steel Pipe

-

19 PCS Drill Bit Sets

19 PCS Drill Bit Sets