ERW Steel Pipe (Electric Resistance Welding)

Our high frequency straight seam electric resistance welded steel pipe, referred to as ERW steel pipe, is produced in strict accordance with international standards, such as API 5L, ASTM A53, etc. It is available in a large selection of dimensions and wall thickness options.

Production Process

The hot rolled coil is formed into a cylindrical shape via the forming machine. Then, the edge of the tube billet is heated and melted by exploiting the skin effect and proximity effect of high frequency current. After that, the ERW steel pipe is obtained by means of pressure welding under the action of the squeezer roller.

| Type | ERW Carbon Steel Pipe |

| Dimensions | 355×6-30 mm |

| Wall Thickness | 6-30mm |

| Material | GR.A, GA.B, X42, X46, X52, X56, X60, X70, J-55, N-80 |

| Standard | ASTM A53, API 5L, DIN1626, JISG3452, JSSG3457 |

| Packing Mode | Customarily, the products are fitted with plastic cap and tied with the steel strip into the hexagonal bundle. We can also pack the product by following the requirements of customers. |

| Surface Treatment | Black varnish, corrosion resistant oil, galvanization or as required by customers |

Our welded pipe production line can manufacture not only the ERW steel pipe, but also other products like square tube, rectangular tube, steel sheet pile, etc. It is equipped with lots of sophisticated equipment, such as solid-state high frequency welding machine, intermediate frequency heat treatment machine, dual channel ultrasonic flaw detector, hydrostatic testing machine, shearing and butt welding machine, super spiral accumulator and microcomputer control flying saw, to fulfill high production automation degree as well as stable and reliable process control.

Application

The ERW steel pipe is primarily applied in the water supply engineering, petrochemical industry, chemical industry, electric power industry, agricultural irrigation and urban construction.

1. For liquid delivery: water supply and drainage

2. For gas delivery: convey coal gas, vapor and liquefied petroleum gas

3. For structural use: pile tube, bridge, wharf, road, building, etc.

Links:https://www.globefindpro.com/products/84890.html

-

Lincoln Air Suspension Parts

Lincoln Air Suspension Parts

-

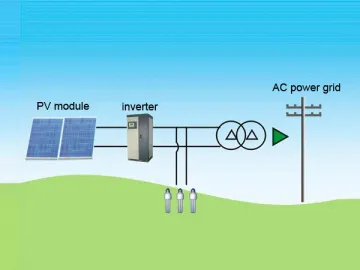

On Grid/Grid Tie Solar Power System

On Grid/Grid Tie Solar Power System

-

Diamond Saw Blade

Diamond Saw Blade

-

Masonry Drill Bits

Masonry Drill Bits

-

Foldable Solar Energy Power System

Foldable Solar Energy Power System

-

TCT Saw Blade

TCT Saw Blade

-

Hot Rolled Seamless Steel Pipe

Hot Rolled Seamless Steel Pipe

-

API Steel Pipe

API Steel Pipe

-

Solar Laptop Battery Charger

Solar Laptop Battery Charger

-

2 Layer PE Coated Steel Pipe

2 Layer PE Coated Steel Pipe

-

29 PCS Drill Bit Sets

29 PCS Drill Bit Sets

-

Monocrystalline Solar Panel

Monocrystalline Solar Panel