Rigid PU Foam Insulation for Water Heater

The rigid PU foam insulation is chiefly used to water heater. It includes system polyol and isocyanate. System polyol is made of polyether polyol, blowing agent, silicone surfactant, catalyst, and additives. Such three foaming systems as HCFC-141B, cyclopentane, and all-water-blown based type, are for your choice.

Product Performance

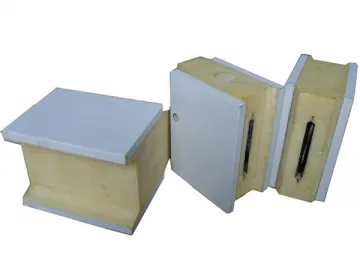

This product has been testified by the market for years. It comes with high compressive strength, good dimensional stability, and low heat conductivity coefficient. Our product has the same level performances as its international advanced congeneric product does.

This rigid PU foam insulation is well-adapted. It is suitable for various production conditions, such as high or low pressure foaming machine, manual foaming, etc.

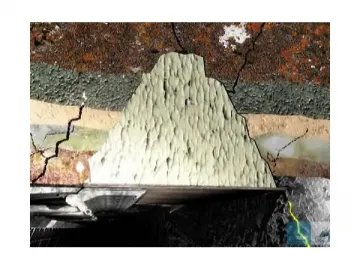

LC-2127G Rigid PU Foam Insulation for Water Heater

Technical Property| Product | LC-2127G | ||

| Manual | Machine | ||

| Blowing agent | type | HCFC-141b | |

| Mixing ratio | (pol/iso) | 100/100 | 100/100~108 |

| Cream time | Sec. | 13~16 | 8~11 |

| Gel time | Sec. | 70~75 | 50±5 |

| Track free time | Sec. | 110~120 | 75±5 |

| Free rise density | kg/m³ | 27~28 | 27~28.5 |

| Molded density | kg/m³ | / | 36~38 |

| GB/T 26709-2011 Rigid polyurethane foam for solar water heaters | ||||

| Items | Unit | All-water-blown | Other blowing agent | |

| Thermal conductivity (Average temperature 23ºC) | ||||

| 7 days after manufactured | ≤ | W/m.k | 0.026 | 0.023 |

| 28 days after manufactured | ≤ | W/m.k | 0.03 | 0.028 |

| Compressive strength (10% | ≥ | MPa | 150 | 130 |

| Deformation) | ||||

| Dimensional stability (100±3)ºC, 48h (-30±3)ºC, 24h | ||||

| ≤ | % | 1.5 | ||

| ≤ | % | 1 | ||

| Apparent core density | kg/m³ | 32~45 | 30~40 | |

| Closed cell rate | ≥ | % | 90 | |

| Water absorption | ≤ | % | 5 | |

| Moisture vapor transmission | ≤ | ng/Pa.m.s | 6.5 or by negotiation | |

| 38ºC, RH0~88% | ||||

LC-2130GCP Rigid PU Foam Insulation for Water Heater

Product Property| Product | LC-2130GCP | ||

| Manual | Machine | ||

| Blowing agent | type | Cyclopentane | |

| Mixing ratio | (pol/iso) | 100/120 | |

| Cream time | Sec. | 12~14 | 8~10 |

| Gel time | Sec. | 80±5 | 60±5 |

| Track free time | Sec. | 140±5 | 90±5 |

| Free rise density | kg/m³ | 27~28 | 27~28 |

| Molded density | kg/m³ | / | 36~38 |

| GB/T 26709-2011 Rigid polyurethane foam for soloar water heaters | ||||

| Items | Unit | All-water-blown | Other blowing agent | |

| Thermal conductivity (Average temperature 23ºC) | ||||

| 7 days after manufactured | ≤ | W/m.k | 0.026 | 0.023 |

| 28 days after manufactured | ≤ | W/m.k | 0.03 | 0.028 |

| Compressive strength (10% Deformation) | ≥ | MPa | 150 | 130 |

| Dimensional stability (100±3)ºC, 48h (-30±3)ºC, 24h | ||||

| ≤ | % | 1.5 | ||

| ≤ | % | 1 | ||

| Apparent core density | kg/m³ | 32~45 | 30~40 | |

| Closed cell rate | ≥ | % | 90 | |

| Water absorption | ≤ | % | 5 | |

| Moisture vapor transmission 38ºC, RH0~88% | ≤ | ng/Pa.m.s | 6.5 or by negotiation | |

LC-2132GH Rigid PU Foam Insulation for Water Heater

Technical Property| Product | LC-2132GH | ||

| Manual | Machine | ||

| Blowing agent | type | All water | |

| Mixing ratio | (pol/iso) | 100/130~140 | 8~11 |

| Cream time | Sec. | 12~15 | 48±5 |

| Gel time | Sec. | 60~70 | 70±5 |

| Track free time | Sec. | 100~110 | 32~34 |

| Free rise density | kg/m³ | 32~34 | 41~45 |

| Molded density | kg/m³ | / | 8~11 |

| GB/T 26709-2011 Rigid polyurethane foam for solar water heaters | ||||

| Items | Unit | All-water-blown | Other blowing agent | |

| Thermal conductivity (Average temperature 23ºC) | ||||

| 7 days after manufactured | ≤ | W/m.k | 0.026 | 0.023 |

| 28 days after manufactured | ≤ | W/m.k | 0.03 | 0.028 |

| compressive strength 10% deformation: | ≥ | MPa | 150 | 130 |

| Dimensional stability (100±3)ºC, 48h (-30±3)ºC, 24h | ||||

| ≤ | % | 1.5 | ||

| ≤ | % | 1 | ||

| Apparent core density | kg/m³ | 32~45 | 30~40 | |

| Closed cell rate | ≥ | % | 90 | |

| Water absorption | ≤ | % | 5 | |

| Moisture vapor transmission (38ºC, RH0~88%) | ≤ | ng/Pa.m.s | 6.5 or by negotiation | |

Related Names

High Density Polyurethane Foam | Polyurethane Polyether | Rigid Urethane Foam

Links:https://www.globefindpro.com/products/85057.html

-

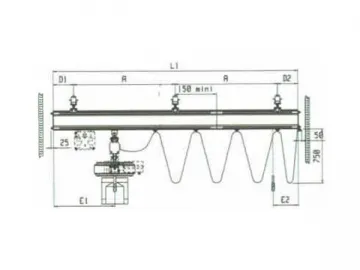

Gantry Crane

Gantry Crane

-

Double Side Aluminum Foil Coated PU Insulated Sandwich Panel

Double Side Aluminum Foil Coated PU Insulated Sandwich Panel

-

Polyether Polyol for Rigid PU Foam

Polyether Polyol for Rigid PU Foam

-

Rigid PU Foam Insulation for Sandwich Panel (Discontinuous Processing)

Rigid PU Foam Insulation for Sandwich Panel (Discontinuous Processing)

-

China Diesel Generator Set

China Diesel Generator Set

-

LC-4000 Rigid PU Foam for Filling and Casting

LC-4000 Rigid PU Foam for Filling and Casting

-

Electric Wire Rope Hoist

Electric Wire Rope Hoist

-

Remote Control RGB LED Flood Light

Remote Control RGB LED Flood Light

-

Solar LED Street Light

Solar LED Street Light

-

Light Girder Suspension Crane

Light Girder Suspension Crane

-

Hand Chain Hoist

Hand Chain Hoist

-

Suspension Crane

Suspension Crane