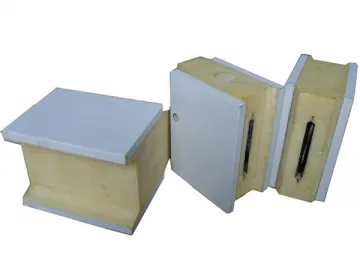

Double Side Aluminum Foil Coated PU Insulated Sandwich Panel

1. Instructions

The double side aluminum foil coated PU insulated sandwich panel which is one-step processed, is suitable for balcony wall mounted solar energy device, air conduct of central air conditioning, and other applications.

2. Advantages

a. Compared to the ordinary type insulation materials, our double side aluminum foil coated PU insulated sandwich panel comes with the characteristics such as light weight, impact resistance, vibration absorption, waterproof performance, etc.

b. Its heat conductivity coefficient is no more than 0.024. In this regard, this type of sandwich panel is ideal building energy-saving materials with excellent heat insulation performance.

c. Our product features good fireproof performance. We can make PU insulated panel with the fireproofing grade of B2 or B3.

d. Due to its excellent thermal insulation performance, the product can increase the indoor usable space as compared to other types of panels. And the building envelope will be thinner.

e. This sort of sandwich panel perfectly resists deformation, and is not prone to cracking. Its beautiful appearance can last for a long time.

f. Because of the special closed-cell structure, it features good heat insulation, antifreeze performance, and sound insulation. In the case of normal use and maintenance, it can be used for at least 30 years.

g. Our product is highly cost effective. Though the rigid polyurethane foam materials have the unit price higher than the traditional thermal insulation materials do, it can greatly reduce the power consumption.

3. Product Performance

This product is in full compliance with Q/0303SLC 002-2013.

| Item | Requirements |

| Insulating Material Density (kg/m3) | ≥35 |

| Heat Conductivity Coefficient w/(m ·k) (Average Temperature 20 ℃) | ≤0.024 |

| Water Absorption Rate (%) | ≤3 |

| Combustion Performance | Not lower than Grade E |

| Remark: B2 level specified by GB8624-1997 | |

Sheet 3-2 Performance of Polyurethane Composite Board

| Item | Requirements |

| Appearance | The panel surface should be flat and smooth, free from bubbles, deformation, scratches, stains, etc. |

| Compressive Strength (Deformation 10 %) (Mpa) | ≥0.15 |

| Tensile Strength (Mpa) | ≥0.10 The breakdown point is inside the insulating materials |

| Combustion Performance | Not lower than Grade E |

| Remark: Equals to the grade B2 specified by GB8624-1997. The product performance can be negotiated by both parties. | |

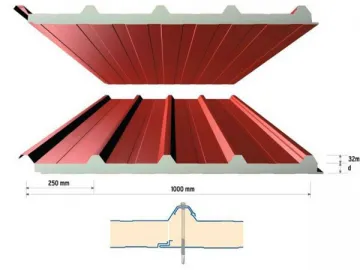

4. Product Specification

Thickness: 20mm~220mm (Customized size is available.

Sheet 4-1 Size Allowable Deviation of Polyurethane Composite Board

| Item | Allowable Deviation(mm) | |

| Thickness | ≤50 | 0.0~1.5 |

| > 50 | 0.0~2.0 | |

| Length | ±2.0 | |

| Width | ±2.0 | |

| Diagonal Difference | 3.0 | |

| Edge Straightness | 2.0 | |

| Panel Flatness | 1.0 | |

| Remark: This sheet is for the panel with the length of 1, 200mm and width of 600mm. For other specifications, the allowable deviations can be negotiated by both parties. | ||

| Wall Mounted Solar Energy Panel | Air Duct |

Related Names

Pre-insulated Ducts | Foil Faced Insulation Board | Aluminum Composite Panels

Links:https://www.globefindpro.com/products/85059.html

-

Polyether Polyol for Rigid PU Foam

Polyether Polyol for Rigid PU Foam

-

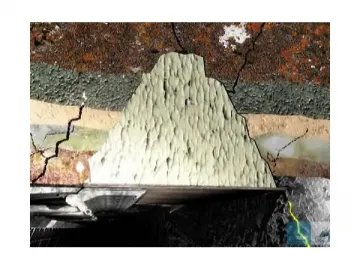

Rigid PU Foam Insulation for Sandwich Panel (Discontinuous Processing)

Rigid PU Foam Insulation for Sandwich Panel (Discontinuous Processing)

-

China Diesel Generator Set

China Diesel Generator Set

-

LC-4000 Rigid PU Foam for Filling and Casting

LC-4000 Rigid PU Foam for Filling and Casting

-

Polyether Polyol for Flexible PU Foam

Polyether Polyol for Flexible PU Foam

-

Rigid PU Foam Insulation for Sandwich Panel (Continuous Processing )

Rigid PU Foam Insulation for Sandwich Panel (Continuous Processing )

-

Gantry Crane

Gantry Crane

-

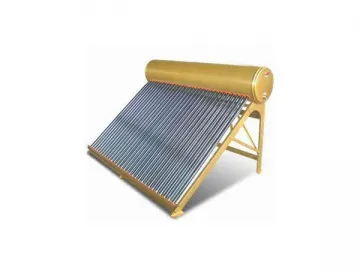

Rigid PU Foam Insulation for Water Heater

Rigid PU Foam Insulation for Water Heater

-

Electric Wire Rope Hoist

Electric Wire Rope Hoist

-

Remote Control RGB LED Flood Light

Remote Control RGB LED Flood Light

-

Solar LED Street Light

Solar LED Street Light

-

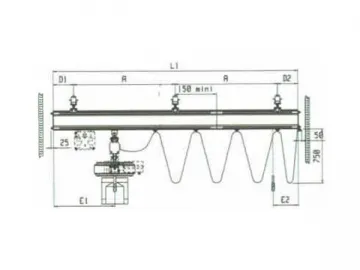

Light Girder Suspension Crane

Light Girder Suspension Crane