Polyether Polyol for Rigid PU Foam

Application

Polyether Polyol for Rigid PU Foam Insulation

Polyether Polyol for Rigid Foam and Crosslinking Agent

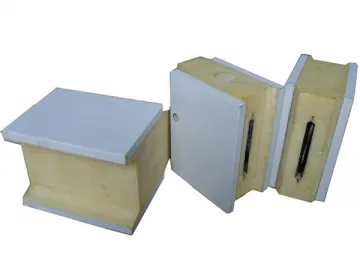

| Freezer | Refrigerator | Pipeline Insulation | Refrigeration House |

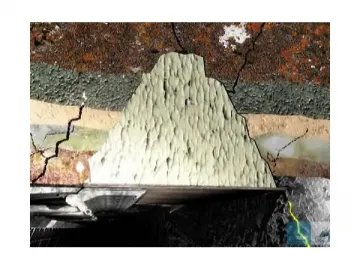

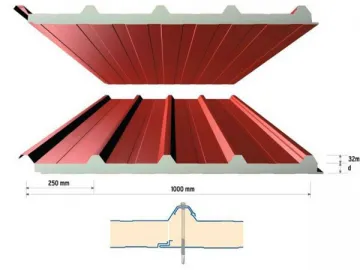

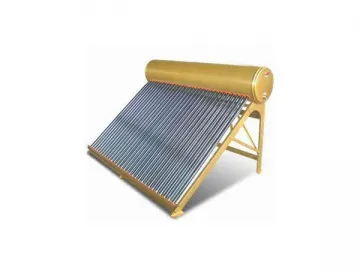

| Polyurethane Coating | Polyurethane Foam Sealing Agent | Solar Water Heater | External Wall Insulation |

Polyether Polyol for Rigid PU Foam Insulation

| Model | LSU-450L |

| Hydroxy1 Value (mgKOH /g) | 435-465 |

| Acid Value (mgKOH/g) | ≤0.50 |

| Water Content(%) | ≤0.20 |

| pH | 4-7 |

| Viscosity(mPa · s/ 25℃) | 7000-10000 |

| Potassium Content( % ) | ≤0.005 |

| Chromaticity(GD): | ≤8 |

| Usage: | Widely used in refrigerator, freezer, cold room insulation, and so on |

| Features: | LSU-450L, LSU-4410, or LSA-380 polyether comes with moderate degree of functionality and viscosity. It can be used alone, or used with other rigid foam polyther. It is suitable for all kinds of foaming system getting balance between flowability and dimensional stability of the finished foam. LSU-450L and LSA-380 are especially suitable for producing PU foam panels. |

| Model | LSU-4410 |

| Hydroxy1 Value (mgKOH /g) | 435-465 |

| Acid Value (mgKOH/g) | ≤ 0.20 |

| Water Content(%) | ≤ 0.10 |

| pH | 4-6 |

| Viscosity(mPa · s/ 25℃) | 2800-5800 |

| Potassium Content( % ) | |

| Chromaticity(GD): | ≤9 |

| Usage: | Widely used in all kinds of rigid foam insulation |

| Features: | LSU-450L, LSU-4410, or LSA-380 polyether comes with moderate degree of functionality and viscosity. It can be used alone, or used with other rigid foam polyther. It is suitable for all kinds of foaming system getting balance between flowability and dimensional stability of the finished foam. LSU-450L and LSA-380 are especially suitable for producing PU foam panels. |

| Model | LSA-380 |

| Hydroxy1 Value (mgKOH /g) | 365-395 |

| Acid Value (mgKOH/g) | ≤0.30 |

| Water Content(%) | ≤0.20 |

| pH | 4-7 |

| Viscosity(mPa · s/ 25℃) | 2200-3500 |

| Potassium Content( % ) | ≤0.0050 |

| Chromaticity(GD): | ≤8 |

| Usage: | Used in refrigerator, freezer, cold room insulation, and so on.LSA-380 and LSA-460 belong to the same kind rigid polyether, both compatible with cyclopentane system.LSA-380 has low Hydroxyl value and low Viscosity, better flowability; LSA-460 has high Hydroxyl value and high Viscosity, could better the compressive and dimensional stability of finished foam. Can get good result if matching these two materials. |

| Features: | LSU-450L, LSU-4410, or LSA-380 polyether comes with moderate degree of functionality and viscosity. It can be used alone, or used with other rigid foam polyther. It is suitable for all kinds of foaming system getting balance between flowability and dimensional stability of the finished foam. LSU-450L and LSA-380 are especially suitable for producing PU foam panels. |

| Model | LSA-460 |

| Hydroxy1 Value (mgKOH /g) | 445-475 |

| Acid Value (mgKOH/g) | ≤ 0.30 |

| Water Content(%) | ≤ 0.15 |

| pH | 4-7 |

| Viscosity(mPa · s/ 25℃) | 11500-17000 |

| Potassium Content( % ) | ≤0.0050 |

| Chromaticity(GD): | ≤8 |

| Usage: | Used in refrigerator, freezer, cold room insulation, and so on.LSA-380 and LSA-460 belong to the same kind rigid polyether, both compatible with cyclopentane system.LSA-380 has low Hydroxyl value and low Viscosity, better flowability; LSA-460 has high Hydroxyl value and high Viscosity, could better the compressive and dimensional stability of finished foam. Can get good result if matching these two materials. |

| Features: | This product has good compatibility with physical foaming agent. In conjunction with other rigid foam polyether polyol, it is suitable for every kinds of foaming system, especially suitable for pentane foaming system. It can better compressive strength and dimensional stability of finished foam. |

| Model | LSU-310 |

| Hydroxy1 Value (mgKOH /g) | 300-340 |

| Acid Value (mgKOH/g) | ≤ 0.5 |

| Water Content(%) | ≤ 0.20 |

| pH | 4-7 |

| Viscosity(mPa · s/ 25℃) | 1400-2600 |

| Potassium Content( % ) | ≤0.0050 |

| Chromaticity(GD): | ≤8 |

| Usage: | Used in refrigerator, freezer, cold room insulation, and so on.LSA-380 and LSA-460 belong to the same kind rigid polyether, both compatible with cyclopentane system.LSA-380 has low Hydroxyl value and low Viscosity, better flowability; LSA-460 has high Hydroxyl value and high Viscosity, could better the compressive and dimensional stability of finished foam. Can get good result if matching these two materials. |

| Features: | This product has good compatibility with physical foaming agent. In conjunction with other rigid foam polyether polyol, it is suitable for every kinds of foaming system, especially suitable for pentane foaming system. It can better compressive strength and dimensional stability of finished foam. |

| Model | LSU-330 |

| Hydroxy1 Value (mgKOH /g) | 310-350 |

| Acid Value (mgKOH/g) | |

| Water Content(%) | ≤ 0.20 |

| pH | |

| Viscosity(mPa · s/ 25℃) | ≤ 2500 |

| Potassium Content( % ) | ≤0.0050 |

| Chromaticity(GD): | ≤8 |

| Usage: | Used in refrigerator, freezer, cold room insulation, and so on.LSA-380 and LSA-460 belong to the same kind rigid polyether, both compatible with cyclopentane system.LSA-380 has low Hydroxyl value and low Viscosity, better flowability; LSA-460 has high Hydroxyl value and high Viscosity, could better the compressive and dimensional stability of finished foam. Can get good result if matching these two materials. |

| Features: | This product has good compatibility with physical foaming agent. In conjunction with other rigid foam polyether polyol, it is suitable for every kinds of foaming system, especially suitable for pentane foaming system. It can better compressive strength and dimensional stability of finished foam. |

| Model | LSU-360 |

| Hydroxy1 Value (mgKOH /g) | 385-405 |

| Acid Value (mgKOH/g) | |

| Water Content(%) | ≤ 0.20 |

| pH | 9-12 |

| Viscosity(mPa · s/ 25℃) | 9000-12000 |

| Potassium Content( % ) | ≤0.0050 |

| Chromaticity(GD): | ≤8 |

| Usage: | Can be used in polyurethane foam insulation. Widely, mainly used in pipe insulation. |

| Features: | Rigid foam polyether polyol with high functionality, can be used to make all kinds of rigid foam insulation material in conjunction with other rigid foam polyether polyol. It can improve the compressive strength and dimensional stability of finished foam, and prevent foam shrinkage under low temperature. |

| Model | LSA-635S |

| Hydroxy1 Value (mgKOH /g) | 475-505 |

| Acid Value (mgKOH/g) | |

| Water Content(%) | ≤ 0.20 |

| pH | |

| Viscosity(mPa · s/ 25℃) | 4200-5500 |

| Potassium Content( % ) | |

| Chromaticity(GD): | ≤ 8 |

| Usage: | Polymer of Sorbitol, widely used in PU panel, pipe insulation, and so on. |

| Model | LSU-4110 |

| Hydroxy1 Value (mgKOH /g) | 435-465 |

| Acid Value (mgKOH/g) | ≤ 0.20 |

| Water Content(%) | ≤ 0.20 |

| pH | 9-12 |

| Viscosity(mPa · s/ 25℃) | 3000-6000 |

| Potassium Content( % ) | |

| Chromaticity(GD): | ≤8 |

| Usage: | Widely used in refrigerator, freezer, cold room, solar heater, spray, PU panel, pipe insulation and so on. |

| Features: | Broad-spectrum sucrose type rigid foam polyether polyol, can be used as basic material in producing rigid polyurethane foam, and is suitable for all kinds of foaming agent. It is a typical product in rigid foam polyether polyol application. |

| Model | LNT-403A |

| Hydroxy1 Value (mgKOH /g) | 740-790 |

| Acid Value (mgKOH/g) | |

| Water Content(%) | ≤ 0.20 |

| pH | ≤ 13 |

| Viscosity(mPa · s/ 25℃) | 1400-190 (50 ℃) |

| Potassium Content( % ) | |

| Chromaticity(GD): | ≤ 100APHA |

| Usage: | Widely used in refrigerator, freezer, cold room for cold insulation and spray foam, etc. |

| Features: | It has high reactivity and viscosity, in conjunction with other rigid foam polyether polyol, and will be suitable for all kinds of foaming agent system for bettering the reactivity of system polyol and foam dimensional stability. Due to its high reactivity, there will be difficulty in using it alone. And due to its high viscosity, there will be difficulty in using it in Winter. |

Polyether Polyol for Rigid Foam and Crosslinking Agent

| Model | LMN-450 |

| Hydroxy1 Value (mgKOH/g) | 435-465 |

| Acid Value(mgKOH /g) | ≤0.2 |

| Water Content(%) | ≤0.2 |

| pH | 4-7 |

| Chromaticity APHA | 4 |

| Usage: | Used in polyurethane foam sealant and used as crosslinking agent for rigid PU foam and polyurethane elastomer. |

| Features: | a. Used as crosslinking agent in polyurethane elastomer, to increase the hardness of finished ware.b. Used as crosslinking agent in polyurethane rigid foam, so as to lower the viscosity of system polyol. c. Used in foam sealant, to increase the foam hardness and speed up curing time. |

Related Names

Polymeric Foam Polyol | Polyurethane Curing Agent | Foam Preparation Chemicals

Scan QR to Read

Links:https://www.globefindpro.com/products/85060.html

Links:https://www.globefindpro.com/products/85060.html

Recommended Products

-

Rigid PU Foam Insulation for Sandwich Panel (Discontinuous Processing)

Rigid PU Foam Insulation for Sandwich Panel (Discontinuous Processing)

-

China Diesel Generator Set

China Diesel Generator Set

-

LC-4000 Rigid PU Foam for Filling and Casting

LC-4000 Rigid PU Foam for Filling and Casting

-

Polyether Polyol for Flexible PU Foam

Polyether Polyol for Flexible PU Foam

-

Rigid PU Foam Insulation for Sandwich Panel (Continuous Processing )

Rigid PU Foam Insulation for Sandwich Panel (Continuous Processing )

-

Single Cylinder Diesel Engine

Single Cylinder Diesel Engine

-

Double Side Aluminum Foil Coated PU Insulated Sandwich Panel

Double Side Aluminum Foil Coated PU Insulated Sandwich Panel

-

Gantry Crane

Gantry Crane

-

Rigid PU Foam Insulation for Water Heater

Rigid PU Foam Insulation for Water Heater

-

Electric Wire Rope Hoist

Electric Wire Rope Hoist

-

Remote Control RGB LED Flood Light

Remote Control RGB LED Flood Light

-

Solar LED Street Light

Solar LED Street Light

Hot Products