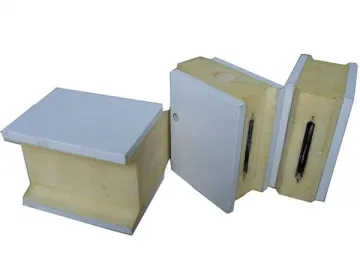

Rigid PU Foam Insulation for Sandwich Panel (Discontinuous Processing)

We have developed the rigid polyurethane foam system for CFC free blown rigid polyurethane sandwich panel. Aside from isocyanate, it also includes system polyol which is mixed with polyol, fire retardant, silicone surfactant, catalyst, and additives. Our rigid PU foam insulation for sandwich panel is made with the discontinuous processing method. It is used to make sandwich panel by filling with dispensing machine or manual pouring in mould.

There are two kinds of foaming systems such as HCFC-141B or all-water-blown based types.

Performance

This rigid PU foam system is good in flowabiltiy, short in stripping time. It is convenient to use. The rigid PU foam comes with uniformly distributed cells, good dimensional stability, and excellent thermal insulation property. It has good viscosity on many substrates. In conclusion, its performance reaches the international advanced level.

LC-7220D Rigid PU Foam Insulation for Sandwich Panel(Discontinuous Processing)

Product Property| Product | LC-7220D | ||

| Manual | Machine | ||

| Blowing agent | type | HCFC-141b | |

| Mixing ratio | (pol/iso) | 100/110 | |

| Cream time | Sec. | 13 | 10 |

| Gel time | Sec. | 80 | 65 |

| Track free time | Sec. | 120 | 100 |

| Free rise density | kg/m3 | 24 | 23 |

| Molded density | kg/m3 | / | 40 |

| Fireproof | grade | B3 | |

| GB/T 21558-2008 refer to ISO4898:2006 Rigid polyurethane cellular plastics used in the thermal insulation of building | ||

| Core density (kg/m3) | ≥ | 35 |

| Compressive strength (10% deformation) | ≥ | 180 |

| Thermal conductivity (W/m.k) (initial thermal conductivity at average temperature 10ºC , 28d or average temperature 23ºC , 28d) | ≤ | 0.022 |

| ≤ | 0.024 | |

| Dimensional stability (%) 48h 70ºC | ≤ | 2 |

| 48h -30ºC | ≤ | 1.5 |

| Compression creep (%) 80ºC, 20kPa, 48h | ≤ | -- |

| 70ºC, 40kPa, 48h | ≤ | 5 |

| Moisture vapor transmission 23ºC, RH0~50% (ng/Pa.m.s) | ≤ | 6.5 |

| Water absorption (%) | ≤ | 3 |

LC-7221H20 Rigid PU Foam Insulation for Sandwich Panel(Discontinuous Processing)

Product Property| Product | LC-7221H20 | ||

| Manual | Machine | ||

| Blowing agent | type | All water | |

| Mixing ratio | (pol/iso) | 100/150 | |

| Cream time | Sec. | 20 | 15 |

| Gel time | Sec. | 150 | 120 |

| Track free time | Sec. | 240 | 200 |

| Free rise density | kg/m3 | 32 | 32 |

| Molded density | kg/m3 | / | 55 |

| Fireproof | grade | B3 | |

| GB/T 21558-2008 refer to ISO4898:2006 Rigid polyurethane cellular plastics used in the thermal insulation of building | ||

| Core density (kg/m3) | ≥ | 35 |

| Compressive strength (10% deformation) | ≥ | 180 |

| Thermal conductivity (W/m.k) (initial thermal conductivity at average temperature 10ºC , 28d or average temperature 23ºC , 28d) | ≤ | 0.022 |

| ≤ | 0.024 | |

| Dimensional stability (%) 48h 70ºC | ≤ | 2 |

| 48h -30ºC | ≤ | 1.5 |

| Compression creep (%) 80ºC, 20kPa, 48h | ≤ | -- |

| 70ºC, 40kPa, 48h | ≤ | 5 |

| Moisture vapor transmission 23ºC, RH0~50% (ng/Pa.m.s) | ≤ | 6.5 |

| Water absorption (%) | ≤ | 3 |

LC-7225 Rigid PU Foam Insulation for Sandwich Panel(Discontinuous Processing)

Product Property| Product | LC-7225 | ||

| Manual | Machine | ||

| Blowing agent | type | HCFC-141b | |

| Mixing ratio | (pol/iso) | 100/140 | |

| Cream time | Sec. | 20 | 15 |

| Gel time | Sec. | 120 | 100 |

| Track free time | Sec. | 200 | 180 |

| Free rise density | kg/m3 | 30 | 30 |

| Molded density | kg/m3 | / | 50 |

| Fireproof | grade | B2 | |

| GB/T 21558-2008 refer to ISO4898:2006 Rigid polyurethane cellular plastics used in the thermal insulation of building | ||

| Core density (kg/m3) | ≥ | 35 |

| Compressive strength (10% deformation) | ≥ | 180 |

| Thermal conductivity (W/m.k) (initial thermal conductivity at average temperature 10ºC , 28d or average temperature 23ºC , 28d) | ≤ | 0.022 |

| ≤ | 0.024 | |

| Dimensional stability (%) 48h 70ºC | ≤ | 2 |

| 48h -30ºC | ≤ | 1.5 |

| Compression creep (%) 80ºC, 20kPa, 48h | ≤ | -- |

| 70ºC, 40kPa, 48h | ≤ | 5 |

| Moisture vapor transmission 23ºC, RH0~50% (ng/Pa.m.s) | ≤ | 6.5 |

| Water absorption (%) | ≤ | 3 |

LC-7230 Rigid PU Foam Insulation for Sandwich Panel(Discontinuous Processing)

Product Property| Product | LC-7230 | ||

| Manual | Machine | ||

| Blowing agent | type | HCFC-141b | |

| Mixing ratio | (pol/iso) | 100/180 | |

| Cream time | Sec. | 15 | 12 |

| Gel time | Sec. | 70 | 60 |

| Track free time | Sec. | 100 | 80 |

| Free rise density | kg/m3 | 32 | 35 |

| Molded density | kg/m3 | / | 55 |

| Fireproof | grade | B1 | |

| GB/T 21558-2008 refer to ISO4898:2006 Rigid polyurethane cellular plastics used in the thermal insulation of building | ||

| Core density (kg/m3) | ≥ | 35 |

| Compressive strength (10% deformation) | ≥ | 180 |

| Thermal conductivity (W/m.k) (initial thermal conductivity at average temperature 10ºC , 28d or average temperature 23ºC , 28d) | ≤ | 0.022 |

| ≤ | 0.024 | |

| Dimensional stability (%) 48h 70ºC | ≤ | 2 |

| 48h -30ºC | ≤ | 1.5 |

| Compression creep (%) 80ºC, 20kPa, 48h | ≤ | -- |

| 70ºC, 40kPa, 48h | ≤ | 5 |

| Moisture vapor transmission 23ºC, RH0~50% (ng/Pa.m.s) | ≤ | 6.5 |

| Water absorption (%) | ≤ | 3 |

Related Names

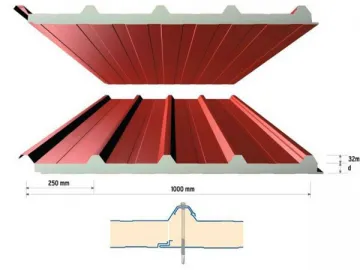

Urethane Foam Sheet | Polyurethane Rigid Wall Panel | Roof Insulation Foam Board

Links:https://www.globefindpro.com/products/85061.html

-

China Diesel Generator Set

China Diesel Generator Set

-

LC-4000 Rigid PU Foam for Filling and Casting

LC-4000 Rigid PU Foam for Filling and Casting

-

Polyether Polyol for Flexible PU Foam

Polyether Polyol for Flexible PU Foam

-

Rigid PU Foam Insulation for Sandwich Panel (Continuous Processing )

Rigid PU Foam Insulation for Sandwich Panel (Continuous Processing )

-

Single Cylinder Diesel Engine

Single Cylinder Diesel Engine

-

Three Cylinder Diesel Engine

Three Cylinder Diesel Engine

-

Polyether Polyol for Rigid PU Foam

Polyether Polyol for Rigid PU Foam

-

Double Side Aluminum Foil Coated PU Insulated Sandwich Panel

Double Side Aluminum Foil Coated PU Insulated Sandwich Panel

-

Gantry Crane

Gantry Crane

-

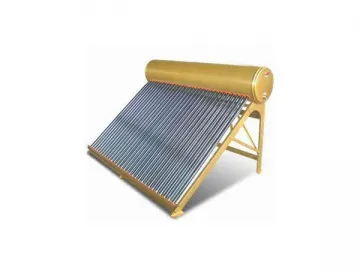

Rigid PU Foam Insulation for Water Heater

Rigid PU Foam Insulation for Water Heater

-

Electric Wire Rope Hoist

Electric Wire Rope Hoist

-

Remote Control RGB LED Flood Light

Remote Control RGB LED Flood Light