LC-4000 Rigid PU Foam for Filling and Casting

1. General Description

As a two component polyurethane system, LC-4000 rigid PU foam is fine-celled foam produced by the polyol and isocyanate that are mixed in correct proportions. It is designed for such use as filling and casting in the moulding applications where good skin is required.

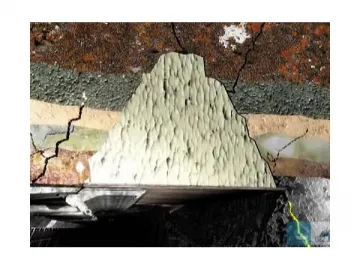

This product can be applied to mould various components, including pipe shell, handmade article, mine plugging, as well as intricate mouldings such as fishing lures. It can be manually drill mixed, and the minimum speed is 2000 rpm. However, it should be processed by low-pressure plural polyurethane dispensing equipment.

2. Performance

This PU foam system has good flowability and short demoulding time. And the PU foam comes with uniform fine cells, high surface hardness, and high mechanical strength.

3. Product Property

3.1 Technical Property

| Product Item | For filling | For casting | |

| Machine | Machine | ||

| Mixing Ratio | (pol/iso) | 100/100 | 100/100 |

| Cream Time | Sec. | 14 | 20 |

| Gel Time | Sec. | 45 | 60 |

| Tack Free Time | Sec. | 63 | 70 |

| Free Rise Density | Kg/m3 | 25 | 240 |

3.2 Foam Property

| Property | Unit | Value | |

| For filling | For casting | ||

| Moulded Density | kg/m3 | 42 | ≥ 310 |

| Closed Cell Content | % | ≥ 90 | ≥ 91 |

| Dimensional Stability | % | < 1 | < 0.6 |

| Coefficient of Thermal Conductivity | W/m K | ≤ 0.024 | ≤ 0.024~0.022 |

| Compressive Strength (10% Deformation) | Mpa | ≥ 0.20 | ≥ 0.5 |

Related Names

Polyurethane Pour Foam | Hot Cast Elastomer | Self Skinning Urethane Foam

Links:https://www.globefindpro.com/products/85063.html

-

Polyether Polyol for Flexible PU Foam

Polyether Polyol for Flexible PU Foam

-

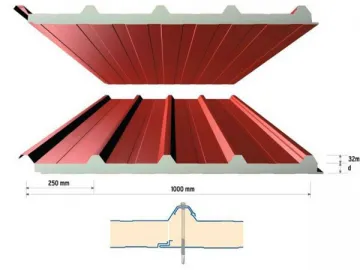

Rigid PU Foam Insulation for Sandwich Panel (Continuous Processing )

Rigid PU Foam Insulation for Sandwich Panel (Continuous Processing )

-

Single Cylinder Diesel Engine

Single Cylinder Diesel Engine

-

Three Cylinder Diesel Engine

Three Cylinder Diesel Engine

-

Marine Diesel Engine

Marine Diesel Engine

-

Polyol Blend for Flexible PU Foam

Polyol Blend for Flexible PU Foam

-

China Diesel Generator Set

China Diesel Generator Set

-

Rigid PU Foam Insulation for Sandwich Panel (Discontinuous Processing)

Rigid PU Foam Insulation for Sandwich Panel (Discontinuous Processing)

-

Polyether Polyol for Rigid PU Foam

Polyether Polyol for Rigid PU Foam

-

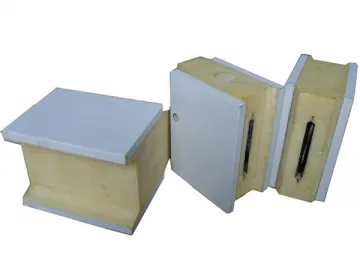

Double Side Aluminum Foil Coated PU Insulated Sandwich Panel

Double Side Aluminum Foil Coated PU Insulated Sandwich Panel

-

Gantry Crane

Gantry Crane

-

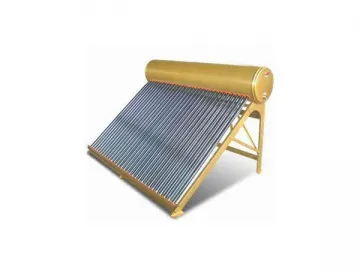

Rigid PU Foam Insulation for Water Heater

Rigid PU Foam Insulation for Water Heater