LC-5000 Rigid PU Foam for Wood Imitation Product

1. General Description

The LC-5000 rigid PU foam is designed for making wood imitation furniture and decorations. Apart from isocyanate, this two component polyurethane foam system also consists of system polyol. Formula of system polyol covers polyether polyol, blowing agent, silicone surfactant, catalyst, and additives. Upon request, flame retardant can be added.

2. Product Performance

This polyurethane foam system has good flowabiltiy and short demoulding time. The PU foam product comes with the features such as uniform fine cells, high surface hardness, and smooth surface. Its density is adjustable among 120-1000kg/m³. In a word, the PU foam product performance reaches the international advanced level.

Especially, wood imitation product made of LC-5000 rigid PU foam holds the advantages such as high strength, good toughness, simple forming technology, etc. Its strength is higher than that of natural wood, while its density is lower than the natural wood’s. The density range is from 300~1000kg/m3. Consequently, it is an ideal substitute for wood.

3. Product Property

3.1 Technical property

| Product Item | LC-5000 |

| Manual | |

| Blowing Agent | HCFC-141b or water |

| Mixing Ratio (pol/iso) | 100/100 |

| Cream Time (Sec.) | 20~60 |

| Gel Time (Sec.) | 110~180 |

| Track Free Time (Sec.) | 130~200 |

| Free Rise Density (Kg/m3) | 100~300 |

3.2 Foam performance

| Item | Property |

| Moulded Density, kg/M3 | 300-600 |

| Curving Strength, Mpa | 7-20 |

| Compressive Strength, Mpa | 10-20 |

| Tensile Strength, Mpa | 10-25 |

| Surface Strength, Shore D | 50-80 |

| Shrinking Ratio, % | ≤0.3 |

4. Packing

New steel drums, IBC drums, in bulk or Isotank.

5. Handling

Avoid any contact with skin or eyes. When working with these chemicals, you must wear safety goggles, protective gloves, and overalls.

6. Storage

The materials are sensitive to humidity. Therefore, partially used drums should be tightly sealed to prevent moisture from getting inside.

a. Polyol Blend

When stored at the room temperature of 20-30℃, the Polyol blend has a shelf life of three to six months since the production date. It is recommended thoroughly mixed prior to use.

b. Isocyanate

When stored at the room temperature ranging from 20 to 30℃, the Isocyanate has one-year shelf life since the production date. Do not store it at the temperature of below 0℃, as some crystallization may occur. The storage temperature should not be above 50℃, for avoiding the possible formation of insoluble solids.

LC-5000 Rigid PU Foam for Wood Imitation Product

Related Names

Faux Wood Polyether Urethane | Molded Polyurethane Foam | Decorative Foam

Links:https://www.globefindpro.com/products/85070.html

-

Explosion-Proof Electric Hoist

Explosion-Proof Electric Hoist

-

Deutz Diesel Generator Set

Deutz Diesel Generator Set

-

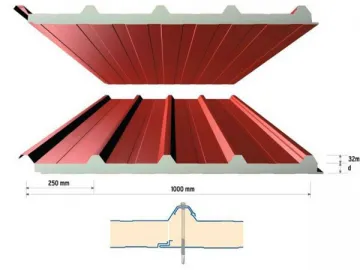

Fiberglass Reinforced PU Insulated Sandwich Panel

Fiberglass Reinforced PU Insulated Sandwich Panel

-

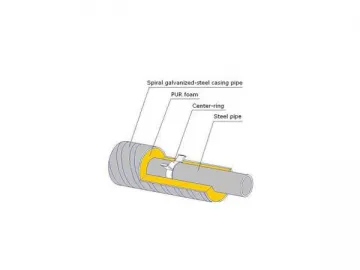

Rigid PU Foam Pipe Insulation

Rigid PU Foam Pipe Insulation

-

LC-5000 Rigid PU Foam for Packaging

LC-5000 Rigid PU Foam for Packaging

-

Diesel and Gas Generator Set

Diesel and Gas Generator Set

-

Polyol Blend for Flexible PU Foam

Polyol Blend for Flexible PU Foam

-

Marine Diesel Engine

Marine Diesel Engine

-

Three Cylinder Diesel Engine

Three Cylinder Diesel Engine

-

Single Cylinder Diesel Engine

Single Cylinder Diesel Engine

-

Rigid PU Foam Insulation for Sandwich Panel (Continuous Processing )

Rigid PU Foam Insulation for Sandwich Panel (Continuous Processing )

-

Polyether Polyol for Flexible PU Foam

Polyether Polyol for Flexible PU Foam