Fiberglass Reinforced PU Insulated Sandwich Panel

1. Product Instruction

The fiberglass reinforced PU insulated sandwich panel is one-time continuously processed from the two-sided flexible surface materials and rigid polyurethane foam. Its middle PU rigid foam insulating layer applies the advanced technologies for the materials mixing and distributing, so as to ensure the fine cells, uniform density, high strength, and excellent heat-insulating property.

2. Product Advantages

a. Ourfiberglass reinforced PU insulated sandwich panel has high viscosity. Without any binding materials, it can perfectly adhere to the roof or external wall, and has excellent resistance to wind. Compared to the other thermal insulation materials, our product can directly adhere to various substrates. The bonding strength is greater than its crack resistant strength. In this regard, the sandwich panel suits to the technical requirements of the domestic external wall insulation project.

b. It has excellent thermal insulation properties with the heat conductivity coefficient of no more than 0.024. The 40mm thick fiberglass reinforced PU insulated sandwich panel has the same thermal insulation effect as that of 80mm thick EPS, 90MM thick mineral wool, 200mm thick cork wood, 760mm thick lightweight concrete, or 1720mm common bricks. That means our product can enlarge the usable space.

c. We can produce the Grade B1, B2, and B3 series fire proof PU panels.

d. The PU panel has excellent resistance to deformation, crack.

e. This material is made up of numerous closed cells, so it comes with stable structure. It has good anti-frost property and sound insulation as well. Under the condition of normal use and maintenance, it has the service of at least 30 years.

f. Our product is highly cost effective. Although the unit price is higher than that of the traditional thermal insulation materials, it requires extremely less power consumption.

3. Product Performance

Our fiberglass reinforced PU insulated sandwich panel complies with Q/0303SLC 002-2013

| Item | Requirements |

| Insulating Material Density (kg/m3) | ≥35 |

| Heat Conductivity Coefficient w/(m ·k) (Average Temperature 20 ℃) | ≤0.024 |

| Water Absorption Rate (%) | ≤3 |

| Combustion Performance | Not lower than Grade E |

| Remark: B2 level specified by GB8624-1997 | |

Sheet 3-2 Performance of Polyurethane Composite Board

| Item | Requirement |

| Appearance | The panel surface should be flat and smooth, free from bubbles, deformation, scratches, stains, etc. |

| Compressive Strength (Deformation 10%)(Mpa) | ≥0.15 |

| Tensile Strength (Mpa) | ≥0.10 The breakdown point is inside the insulating materials |

| Combustion Performance | Not lower than Grade E |

| Remark: Be equivalent to the grade B2 specified by GB8624-1997. The product performance can be negotiated by both parties. | |

4. Product Specification

Thickness: 20mm~220mm (Customized size is available.)

Sheet 4-1 Allowable Deviation of Polyurethane Composite Board Size

| Item | Allowable Deviation (mm) | |

| Thickness | ≤50 | 0.0~1.5 |

| >50 | 0.0~2.0 | |

| Length | ±2.0 | |

| Width | ±2.0 | |

| Diagonal Difference | 3.0 | |

| Edge Straightness | 2.0 | |

| Panel Flatness | 1.0 | |

| Remark: This sheet is for the panel with the length of 1200mm and width of 600mm. For other specifications, the allowable deviations can be discussed by both parties. | ||

External Wall Insulation System

1. Basic Level Wall

2. Polyurethane Composite Board

3. Mortar

4. Galvanized Steel Wire

5. Adhesive for Face Brick

6. Face Brick

7. Face Brick Crack-sealer

1. Basic Level Wall

2. PU Insulated Sandwich Panel

3. Mortar

4. Alkaliproof Fiberglass Gridding Cloth

5. Flexible Waterproof Putty

6. Coating

Related Names

Exterior Wall Cladding | Architectural Wall Panels | Fiberglass Composite Panels

Links:https://www.globefindpro.com/products/85073.html

-

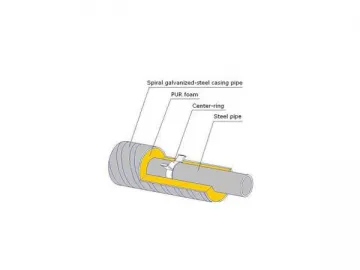

Rigid PU Foam Pipe Insulation

Rigid PU Foam Pipe Insulation

-

LC-5000 Rigid PU Foam for Packaging

LC-5000 Rigid PU Foam for Packaging

-

Diesel and Gas Generator Set

Diesel and Gas Generator Set

-

Push and Geared Trolley

Push and Geared Trolley

-

Rigid PU Foam Insulation for Refrigerator and Freezer

Rigid PU Foam Insulation for Refrigerator and Freezer

-

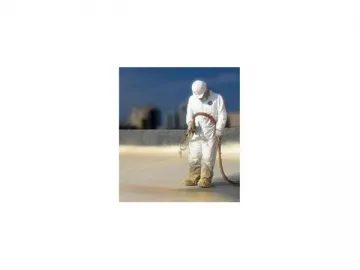

Rigid PU Spray Foam Insulation

Rigid PU Spray Foam Insulation

-

Deutz Diesel Generator Set

Deutz Diesel Generator Set

-

Explosion-Proof Electric Hoist

Explosion-Proof Electric Hoist

-

LC-5000 Rigid PU Foam for Wood Imitation Product

LC-5000 Rigid PU Foam for Wood Imitation Product

-

Polyol Blend for Flexible PU Foam

Polyol Blend for Flexible PU Foam

-

Marine Diesel Engine

Marine Diesel Engine

-

Three Cylinder Diesel Engine

Three Cylinder Diesel Engine