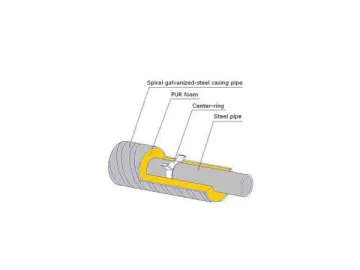

Rigid PU Foam Pipe Insulation

The rigid PU foam pipe insulation is comprised of system polyol and isocyanate. System polyol is the mixture of polyol, water, silicone surfactant, catalyst, and additives. It is developed for CFC free blown rigid foam insulation. You can choose the HCFC-141B or all-water-blown based foaming system.

The pipe produced by HCFC-141B blown system polyol has passed pipe anti-aging test per CJ/T114-2000 and creep test per EN253:2003.

Product Performance

This product has the characteristics such as high compressive strength, good dimensional stability, and low heat conductivity coefficient. It is applicable for different production conditions, for instance high or low pressure foaming machine, manual foaming, etc.

Remark

CJ/T114-2000: Preformed directly buried insulating pipes for polyurethane [PUR] foamed-plastics and high density polyethylene [PE] protect pipes

EN253:2003: District heating pipes - Pre-insulated bonded pipe systems for directly buried hot water networks - Pipe assembly of steel service pipe, polyurethane thermal insulation and outer casing of polyethylene.

LC-3130 Rigid PU Foam for Pre-Insulated Pipe (Two Step)

Product Property

| Product | LC-3130 | |

| Manual | ||

| Blowing agent | type | HCFC-141b |

| Mixing ratio | (pol/iso) | 100/100 |

| Cream time | Sec. | 22~28 |

| Gel time | Sec. | 80~110 |

| Track free time | Sec. | 120~160 |

| Free rise density | kg/m³ | 40~45 |

| Pipe diameter(applicability) | ≤Φ426, temperature resistant 130ºC | |

Foam Property

| CJ/T 114-2000 NEQ EN253:1994 Performed directly buried insulating pipes for polyurethane (PUR) foamed-plastics and high density polyethylene (PE) protect pipes | |

| Average cell size | ≤ 0.5mm |

| Density | ≥ 60kg/m3 |

| Compressive strength (10% deformation) | ≥0.3MPa |

| Water absorption in boiled water 90 min. | ≤10% |

| Thermal conductivity (not aged) | ≤0.033W/(m.k) |

LC-3130 Rigid PU Foam for Pre-Insulated Pipe (Two Step)

LC-3132 Rigid PU Foam for Pre-Insulated Pipe (One Step)

Product Property

| Product | LC-3132 | |

| Manual | ||

| Blowing agent | type | HCFC-141b |

| Mixing ratio | (pol/iso) | 100/100 |

| Cream time | Sec. | 11~26 |

| Gel time | Sec. | 30~75 |

| Track free time | Sec. | / |

| Free rise density | kg/m³ | 35~50 |

| Pipe diameter(applicability) | ≤Φ426 | |

Foam Property

| SY/T 0415-1996 Standard of polyurethane foamed coating for buried steel pipeline | |

| Closed cell rate | ≥ 88% |

| Density | 40~60kg/m3 |

| Compressive strength (10% deformation) | ≥0.2MPa |

| Water absorption | < 3% |

| Thermal conductivity (not aged) | ≤0.03 W/(m.k) |

LC-3132 Rigid PU Foam for Pre-Insulated Pipe (One Step)

LC-3142 Rigid PU Foam for Pre-Insulated Pipe (One Step)

Product Property

| Product | LC-3142 | |

| Manual | ||

| Blowing agent | type | HCFC-141b |

| Mixing ratio | (pol/iso) | 100/100 |

| Cream time | Sec. | 26~45 |

| Gel time | Sec. | 80~120 |

| Track free time | Sec. | / |

| Free rise density | kg/m³ | 35~50 |

| Pipe diameter(applicability) | ≥Φ426 | |

Foam Property

| SY/T 0415-1996 Standard of polyurethane foamed coating for buried steel pipeline | |

| Closed cell rate | ≥ 88% |

| Density | 40~60kg/m3 |

| Compressive strength (10% deformation) | ≥0.2MPa |

| Water absorption | < 3% |

| Thermal conductivity (not aged) | ≤0.03 W/(m.k) |

LC-3142 Rigid PU Foam for Pre-Insulated Pipe (One Step)

LC-3150 Rigid PU Foam for Pre-Insulated Pipe (Two Step)

Product Property

| Products | LC-3150 | |

| Manual | ||

| Blowing agent | type | HCFC-141b |

| Mixing ratio | (pol/iso) | 100/100 |

| Cream time | Sec. | 25~30 |

| Gel time | Sec. | 110~150 |

| Track free time | Sec. | 160~240 |

| Free rise density | kg/m3 | 40~45 |

| Pipe diameter(applicability) | Φ426~820, temperature resistant 150ºC | |

Foam Property

| CJ/T 114-2000 NEQ EN253:1994 Performed directly buried insulating pipes for polyurethane (PUR) foamed-plastics and high density polyethylene (PE) protect pipes | |

| Average cell size | ≤ 0.5mm |

| Density | ≥ 60kg/m3 |

| Compressive strength (10% deformation) | ≥0.3MPa |

| Water absorption in boiled water 90 min. | ≤10% |

| Thermal conductivity (not aged) | ≤0.033 W/(m.k) |

LC-3150 Rigid PU Foam for Pre-Insulated Pipe (Two Step)

LC-3242H Rigid PU Foam for Pre-Insulated Pipe (Two Step)

Product Property

| Product | LC-3242H | |

| Manual | ||

| Blowing agent | type | All water |

| Mixing ratio | (pol/iso) | 100/150 |

| Cream time | Sec. | 22~28 |

| Gel time | Sec. | 100~130 |

| Track free time | Sec. | 160~220 |

| Free rise density | kg/m3 | 40~45 |

| Pipe diameter(applicability) | ≤Φ426 | |

Foam Property

| CJ/T 114-2000 NEQ EN253:1994 Performed directly buried insulating pipes for polyurethane (PUR) foamed-plastics and high density polyethylene (PE) protect pipes | |

| Average cell size | ≤ 0.5mm |

| Density | ≥ 60kg/m3 |

| Compressive strength (10% deformation) | ≥0.3MPa |

| Water absorption in boiled water 90 min. | ≤10% |

| Thermal conductivity (not aged) | ≤0.033 W/(m.k) |

LC-3242H Rigid PU Foam for Pre-Insulated Pipe (Two Step)

LC-3260Y Rigid PU Foam for Pre-Insulated Pipe (Two Step)

Product Property

| Product | LC-3260Y | |

| Manual | ||

| Blowing agent | type | HCFC-141b |

| Mixing ratio | (pol/iso) | 100/100 |

| Cream time | Sec. | 28~38 |

| Gel time | Sec. | 150~180 |

| Track free time | Sec. | 220~350 |

| Free rise density | kg/m3 | 40~45 |

| Pipe diameter(applicability) | ≥Φ820, temperature resistant 150ºC | |

Foam Property

| CJ/T 114-2000 NEQ EN253:1994 Performed directly buried insulating pipes for polyurethane (PUR) foamed-plastics and high density polyethylene (PE) protect pipes | |

| Average cell size | ≤ 0.5mm |

| Density | ≥ 60kg/m3 |

| Compressive strength (10% deformation) | ≥0.3MPa |

| Water absorption in boiled water 90 min. | ≤10% |

| Thermal conductivity (not aged) | ≤0.033W/(m.k) |

LC-3260Y Rigid PU Foam for Pre-Insulated Pipe (Two Step)

LC-3282H Rigid PU Foam for Pre-Insulated Pipe (Two Step)

Product Property

| Product | LC-3282H | |

| Manual | ||

| Blowing agent | type | All water |

| Mixing ratio | (pol/iso) | 100/150 |

| Cream time | Sec. | 26~33 |

| Gel time | Sec. | 130~160 |

| Track free time | Sec. | 200~300 |

| Free rise density | kg/m3 | 40~45 |

| Pipe diameter(applicability) | Φ426~820, temperature resistant 142ºC | |

Foam Property

| CJ/T 114-2000 NEQ EN253:1994 Performed directly buried insulating pipes for polyurethane (PUR) foamed-plastics and high density polyethylene (PE) protect pipes | |

| Average cell size | ≤ 0.5mm |

| Density | ≥ 60kg/m3 |

| Compressive strength (10% deformation) | ≥0.3MPa |

| Water absorption in boiled water 90 min. | ≤10% |

| Thermal conductivity (not aged) | ≤0.033W/(m.k) |

LC-3282H Rigid PU Foam for Pre-Insulated Pipe (Two Step)

LC-3296H Rigid PU Foam for Pre-Insulated Pipe (Two Step)

Product Property

| Product | LC-3296H | |

| Manual | ||

| Blowing agent | type | All water |

| Mixing ratio | (pol/iso) | 100/150 |

| Cream time | Sec. | 28~37 |

| Gel time | Sec. | 160~180 |

| Track free time | Sec. | 250~350 |

| Free rise density | kg/m3 | 40~45 |

| Pipe diameter(applicability) | ≥Φ820, temperature resistant 142ºC | |

Foam Property

| CJ/T 114-2000 NEQ EN253:1994 Performed directly buried insulating pipes for polyurethane (PUR) foamed-plastics and high density polyethylene (PE) protect pipes | |

| Average cell size | ≤ 0.5mm |

| Density | ≥ 60kg/m3 |

| Compressive strength (10% deformation) | ≥0.3MPa |

| Water absorption in boiled water 90 min. | ≤10% |

| Thermal conductivity (not aged) | ≤0.033W/(m.k) |

LC-3296H Rigid PU Foam for Pre-Insulated Pipe (Two Step)

Related Names

Polyurethane Prepolymer | Rigid Foam Insulation Panel | High Density Foam Sheet

Links:https://www.globefindpro.com/products/85074.html

-

LC-5000 Rigid PU Foam for Packaging

LC-5000 Rigid PU Foam for Packaging

-

Diesel and Gas Generator Set

Diesel and Gas Generator Set

-

Push and Geared Trolley

Push and Geared Trolley

-

Rigid PU Foam Insulation for Refrigerator and Freezer

Rigid PU Foam Insulation for Refrigerator and Freezer

-

Rigid PU Spray Foam Insulation

Rigid PU Spray Foam Insulation

-

Perkins Diesel Generator Set

Perkins Diesel Generator Set

-

Fiberglass Reinforced PU Insulated Sandwich Panel

Fiberglass Reinforced PU Insulated Sandwich Panel

-

Deutz Diesel Generator Set

Deutz Diesel Generator Set

-

Explosion-Proof Electric Hoist

Explosion-Proof Electric Hoist

-

LC-5000 Rigid PU Foam for Wood Imitation Product

LC-5000 Rigid PU Foam for Wood Imitation Product

-

Polyol Blend for Flexible PU Foam

Polyol Blend for Flexible PU Foam

-

Marine Diesel Engine

Marine Diesel Engine