Color-Coated Steel PU Insulated Sandwich Panel

Color-coated steel PU insulated sandwich panel is made up of two steel panels, between which the polyurethane foam is laid.

Advantages

1. The color-coated steel PU insulated sandwich panel is light in weight, easy in installation. With the steel plates as its outer layers, it not only comes with high strength, but also has beautiful appearance.

2. It has a lot of functions, for instance, thermal insulation, sound insulation, vibration absorption, etc. Additionally, the filling system applies the closed cells structure which can put an end to water vapor condensation.

3. Our product has low heat conductivity coefficient that is no more than 0.024. Because of its excellent thermal insulation property, it is really the ideal energy-saving building materials.

4. Currently, we can make Grade B1, B2, and B3 series fire proof PU panels.

5. Under the condition of the same insulation requirement, it can reduce the thickness of the building envelope, thereby increasing the indoor usable area.

6. This type of sandwich panel is resistant to deformation, and not liable to crack.

7. In the case of normal use and maintenance, it has the service life of at least 30 years.

8. Our product is highly cost effective. Though the rigid polyurethane foam materials have the unit price higher than the traditional thermal insulation materials do, it can greatly reduce the power consumption.

Product Performance

This product is in line with executive standard of Q/0303SLC 002-2013.

| Item | Requirements |

| Insulating Material Density (kg/m3) | ≥35 |

| Heat Conductivity Coefficient w/(m ·k) (Average Temperature 20 ℃) | ≤0.024 |

| Water Absorption Rate (%) | ≤3 |

| Combustion Performance | Not lower than Grade E |

| Remark: B2 level specified by GB8624-1997 | |

Sheet 3-2 Performance of Polyurethane Composite Board

| Item | Requirements |

| Appearance | The panel surface should be flat and smooth, free from bubbles, deformation, scratches, stains, etc. |

| Compressive Strength (Deformation 10 %) (Mpa) | ≥0.15 |

| Tensile Strength (Mpa) | ≥0.10 The breakdown point is inside the insulating materials |

| Combustion Performance | Not lower than Grade E |

| Remark: Be equivalent to to the grade B2 specified by GB8624-1997. The product performance can be negotiated by both parties. | |

Product Specification

Thickness: 20mm~220mm (Customized size is available.)

Sheet 4-1 Size Allowable Deviation of Polyurethane Composite Board

| Item | Allowable Deviation(mm) | |

| Thickness | ≤50 | 0.0~1.5 |

| >50 | 0.0~2.0 | |

| Length | ±2.0 | |

| Width | ±2.0 | |

| Diagonal Difference | 3.0 | |

| Edge Straightness | 2.0 | |

| Panel Flatness | 1.0 | |

| Remark: This sheet is for the panel with the length of 1200mm and width of 600mm. For other specifications, the allowable deviations can be discussed by both parties. | ||

| Garage Door | Cold Storage Board | Door Panel |

| External Wall Panel | Roof Panel |

Related Names

Metal Wall Panels | Building Insulation Boards | Fire Resistant Roofing Panels

Links:https://www.globefindpro.com/products/85081.html

-

Cummins Diesel Generator Set

Cummins Diesel Generator Set

-

Electric Chain Hoist

Electric Chain Hoist

-

Explosion-Proof Crane

Explosion-Proof Crane

-

Water Pump Diesel Engine

Water Pump Diesel Engine

-

Coil Tong

Coil Tong

-

Construction Equipment Diesel Engine

Construction Equipment Diesel Engine

-

Perkins Diesel Generator Set

Perkins Diesel Generator Set

-

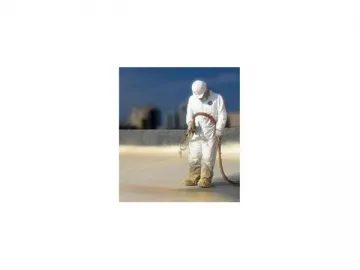

Rigid PU Spray Foam Insulation

Rigid PU Spray Foam Insulation

-

Rigid PU Foam Insulation for Refrigerator and Freezer

Rigid PU Foam Insulation for Refrigerator and Freezer

-

Push and Geared Trolley

Push and Geared Trolley

-

Diesel and Gas Generator Set

Diesel and Gas Generator Set

-

LC-5000 Rigid PU Foam for Packaging

LC-5000 Rigid PU Foam for Packaging