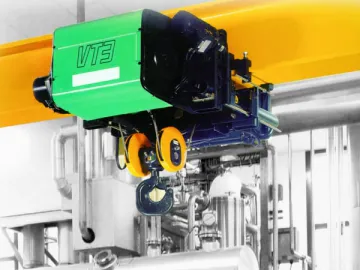

Electric Chain Hoist

The state of the art VR type electric chain hoist is an indispensable item used in the light-duty lifting industries across the world, where the characteristics of reliability is designed into the hoist structure, safety features incorporated into the operating system, and advanced crafting techniques introduced into the modern design.

Made for less volume, lighter weight, and more operating safety and convenience, the chain hoist has the ability to adapt to various working environment, all available at a competitive price. Different models offer choices of lifting capacities ranging between 60kg and 7500kg to suit everyday light-duty lifting work. When used in combination with manually operated trolley, hand-pushed trolley, or motor-driven trolley, the hoist can be mounted on the mono-rail traveling crane, jib crane, and gantry crane. This provides a maximum solution to solve your material handling applications.

VR electric chain hoist aims to provide customers with highest level of safety and reliability. Following is a list of standard configurations of the product.

1. New lifting eye nut with intermediate teeth for perfect chain drive

2. Torque limiter

3. Disk brake for lifting motion

4. Standard lifting height: 3m

5. Double-speed lifting

6. Electrical safety devices for upper and lower lifting position limit.

7. IP55 rated lifting and traveling motor

Tropic-proof protection (lifting and steering – 90 to 95 %)

1. Galvanized lifting chain

2. Emergency punch-stop button

3. Power supply source: 400V/3Ph/50Hz, 415V/3Ph/50 Hz, 460V/3 Ph/60Hz

4. Low voltage 48 V command

5. Speed variation on traveling

6. Comply with CE directives

The electric chain hoist is available with various operational components to suit various applications.

1. Secondary brake for the lifting motor

2. Limit switch for traveling

3. Short headroom trolley

4. Trolley running on curved track

5. Dual-speed traveling trolley carriage (20 & 5 m/min)

6. Slow speed traveling trolley (3 to 10 m/min)

7. High speed traveling trolley

8. Additional button on pendant unit

9. Rain protection

10. Explosion proof hoist

11. Reinforced tropic-proof protection

12. Chain hoist available in a version that complies with CSA standards

13. Manual brake release

For any other special requirements, please contact us.

Chain Hoist Models

| S.W.L.(kg) | Hoist type | F.E.M | Lifting speeds (m/min) | Number of falls | Hoisting motor power(kW) | Fixed hook suspension Unit | Monorail trolley unit | Chain | ||||

| Manually Operated Type | Motorized traveling | 800N/mmx2 | ||||||||||

| Push trolley unit | Chain trolley unit | One speed | Two speed | Variable speeds | ||||||||

| 60 | VL1 0616 b1 | 1Bm | 16/4 | 1 | 0.2/0.05 | · | · | · | · | · | – | 3.1×9.3 |

| VL1 068 b12 | 2m | 8/2 | 1 | 0.2/0.05 | · | · | · | · | · | – | 3.1×9.3 | |

| 80 | VL1 088 b2 | 2m | 8/2 | 1 | 0.2/0.05 | · | · | · | · | · | – | 3.1×9.3 |

| 125 | VL1 128 b1 | 1 Bm | 8/2 | 11 | 0.2/0.05 | · | · | · | · | · | – | 3.1×9.3 |

| VL1 124 b2 | 2m | 4/1 | 1 | 0.2/0.05 | · | · | · | · | · | · | 3.1×9.3 | |

| VL2 124 m2 | 2m | 4 | 1 | 0.4 | · | · | · | · | · | · | 4.8×12.7 | |

| VL2 128 m2 | 2m | 8 | 1 | 0.4 | · | · | · | · | · | · | 4.8×12.7 | |

| VL2 128 b2 | 2m | 8/2 | 1 | 0.4/0.1 | · | · | · | · | · | · | 4.8×12.7 | |

| VL2 1216 b2 | 2m | 16/4 | 1 | 0.8/0.2 | · | · | · | · | · | · | 4.8×12.7 | |

| 250 | VL1 254 b1 | 1Bm | 4/1 | 2 | 0.2 / 0.05 | · | · | · | · | · | · | 3×9 |

| VL2 254 m1 | 1Bm | 4 | 1 | 0.4 | · | · | · | · | · | · | 4.8×12.7 | |

| VL2 258 m2 | 1Bm | 8 | 1 | 0.4 | · | · | · | · | · | · | 4.8×12.7 | |

| VL2 258 b1 | 1Bm | 8/2 | 1 | 0.4/0.1 | · | · | · | · | · | · | 4.8×12.7 | |

| VL5 2516 b1 | 1Bm | 16/4 | 1 | 0.8/0.2 | · | · | · | · | · | · | 4.8×12.7 | |

| VL5 254 b2 | 2m | 4 | 2 | 0.4/0.1 | · | · | · | · | · | · | 4.8×12.7 | |

| VL5 254 m2 | 2m | 4 | 1 | 0.4 | · | · | · | · | · | · | 4.8×12.7 | |

| VL2 258 m2 | 2m | 8 | 1 | 0.8 | · | · | · | · | · | · | 4.8×12.7 | |

| VL5 258 b2 | 2m | 8/2 | 1 | 0.8/0.2 | · | · | · | · | · | · | 4.8×12.7 | |

| 500 | VL2 504 m1 | 1Bm | 4 | 2 | 0.4 | · | · | · | · | · | · | 4.8×12.7 |

| VL5 504 m1 | 1Bm | 4 | 1 | 0.4 | · | · | · | · | · | · | 4.8×12.7 | |

| VL2 504 b1 | 1Bm | 4/1 | 2 | 0.4/0.1 | · | · | · | · | · | · | 4.8×12.7 | |

| VL5 508 m1 | 1Bm | 8 | 1 | 0.8 | · | · | · | · | · | · | 4.8×12.7 | |

| VL5 508 b1 | 1Bm | 8/2 | 1 | 0.8/0.2 | · | · | · | · | · | · | 4.8×12.7 | |

| VL10 5016 b2 | 1Bm | 16/4 | 1 | 1.7/0.4 | · | · | · | · | · | · | 4.8×12.8 | |

| VL5 502 m2 | 2m | 2 | 2 | 0.4 | · | · | · | · | · | · | 4.8×12.7 | |

| VL5 504 m2 | 2m | 4 | 2 | 0.8 | · | · | · | · | · | · | 4.8×12.7 | |

| VL5 504 b2 | 2m | 4 | 2 | 0.8/0.2 | · | · | · | · | · | · | 4.8×12.7 | |

| VL10 504 m2 | 2m | 4 | 1 | 0.8 | · | · | · | · | · | · | 6.8×17.8 | |

| VL10 508 m2 | 2m | 8 | 1 | 1.7/0.4 | · | · | · | · | · | · | 6.8×17.8 | |

| VL10 508 b2 | 2m | 8/2 | 1 | 1.7/0.4 | · | · | · | · | · | · | 6.8×17.8 | |

| 1 000 | VL5 1002 m1 | 1Bm | 2 | 2 | 0.8 | · | · | · | · | · | · | 4.8×12.7 |

| VL5 1004 m1 | 1Bm | 4 | 2 | 0.8 | · | · | · | · | · | · | 4.8×12.7 | |

| VL5 1004 b1 | 1Bm | 4/1 | 2 | 0.8/0.2 | · | · | · | · | · | · | 4.8×12.7 | |

| VL10 1004 m2 | 1Bm | 4 | 1 | 0.8 | · | · | · | · | · | · | 6.8×17.8 | |

| VL10 1008 m1 | 1Bm | 8 | 1 | 1.7 | · | · | · | · | · | · | 6.8×17.8 | |

| VL10 1004 m2 | 2m | 4 | 2 | 1.7 | · | · | · | · | · | · | 6.8×17.8 | |

| VL10 1008 b1 | 1Bm | 8/2 | 1 | 1.7/0.4 | · | · | · | · | · | · | 6.8×17.8 | |

| VL10 1004 b2 | 2m | 4/1 | 2 | 1.7/0.4 | · | · | · | · | · | · | 6.8×17.8 | |

| VL16 10048 b1 | 2m | 8/2 | 1 | 3.5/0.9 | · | · | · | – | – | · | 9×27 | |

| 1 600 | VL10 1602 m1 | 1Bm | 2 | 2 | 0.8 | · | · | · | · | · | · | 6.8×17.8 |

| VL16 1604 m1 | 1Bm | 4 | 2 | 1.7 | · | · | · | · | · | · | 6.8×17.8 | |

| VL10 1604 b1 | 1Bm | 4/1 | 2 | 1.7/0.4 | · | · | · | · | · | · | 6.8×17.8 | |

| VL10 1608 b1 | 1Bm | 8/2 | 1 | 3.5/0.9 | · | · | · | – | – | · | 9×27 | |

| VL25 1606 b2 | 2m | 6.3/1.6 | 1 | 3.5/0.9 | · | · | · | – | – | · | 11.3×31 | |

| 2 000 | VL10 2002 m1 | 1Bm | 4/1 | 2 | 0.8 | · | · | · | · | · | · | 6.8×17.8 |

| VL10 2004 m2 | 1Bm | 4/1 | 4 | 1.7 | · | · | · | · | · | · | 6.8×17.8 | |

| VL10 2004 b1 | 1Bm | 8/2 | 4/.1 | 1.7/0.4 | · | · | · | · | · | · | 6.8×17.8 | |

| VL16 2004 b2 | 2m | 6.3/1.6 | 4/.1 | 3.5/0.9 | · | · | · | – | – | · | 9×27 | |

| VL20 2008 b1 | 1Bm | 0.25/4 | 8/.2 | 3.5/0.9 | · | · | · | – | – | · | 11.3×31 | |

| 2500 | VL16 2504 b1 | 1Bm | 4/1 | 2 | 3.5/0.9 | · | · | · | – | – | · | 9×27 |

| VL20 2504 b2 | 2m | 4/1 | 2 | 3.5/0.9 | · | · | · | – | – | · | 11.3×31 | |

| VL25 2506 b1 | 1Bm | 6.3/1.6 | 1 | 3.5/0.9 | · | · | · | – | – | · | 11.3×31 | |

| 3 200 | VL16 3204 b1 | 1Bm | 4/1 | 2 | 2.5/0.64 | · | · | · | – | – | · | 9×27 |

| VL25 3203 b2 | 2m | 3.2 / 0.75 | 2 | 3.5/0.9 | · | · | · | – | – | · | 11.3×31 | |

| 4 000 | VL20 4004 b1 | 1Bm | 4/1 | 2 | 3.5/0.9 | · | · | · | – | – | · | 11.3×31 |

| VL20 4002 b2 | 2m | 2.7 / 0.7 | 3 | 3.5/0.9 | · | · | · | – | · | – | 11.3×31 | |

| 5 000 | VL25 5003 b1 | 1Bm | 3.2 / 0.75 | 2 | 3.5/0.9 | · | · | · | – | – | · | 11.3×31 |

| VL25 5002 b2 | 2m | 2.1 / 0.5 | 3 | 3.5/0.9 | · | · | · | – | · | – | 11.3×31 | |

| 6 300 | VL20 6302 b1 | 1Bm | 2.7 / 0.7 | 3 | 3.5/0.9 | · | · | · | – | · | – | 11.3×31 |

| 7 500 | VL25 7502 b1 | 1Bm | 2.1 / 0.5 | 3 | 3.5/0.9 | · | · | · | – | · | – | 11.3×31 |

| 10 000 | VL25 10003 b1 | 1Bm | 3.2 / 0.75 | 2×2 | 2×3.5/0.86 | NC | – | – | · | 11.3×31 | ||

| ·: Available in this version -: Not available in this version | ||||||||||||

Above product is powered by VERLINDE

Related Names

Trolley Hoists Supplier | Small Lifting Appliance | Warehouse Lift Tools

Links:https://www.globefindpro.com/products/85083.html

-

Explosion-Proof Crane

Explosion-Proof Crane

-

Water Pump Diesel Engine

Water Pump Diesel Engine

-

Coil Tong

Coil Tong

-

Construction Equipment Diesel Engine

Construction Equipment Diesel Engine

-

Gas Generator Set

Gas Generator Set

-

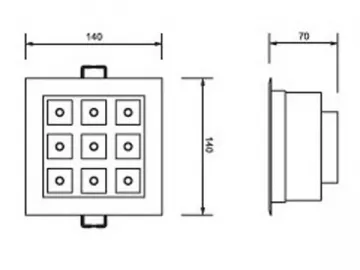

Multi-head LED Grille Light

Multi-head LED Grille Light

-

Cummins Diesel Generator Set

Cummins Diesel Generator Set

-

Color-Coated Steel PU Insulated Sandwich Panel

Color-Coated Steel PU Insulated Sandwich Panel

-

Perkins Diesel Generator Set

Perkins Diesel Generator Set

-

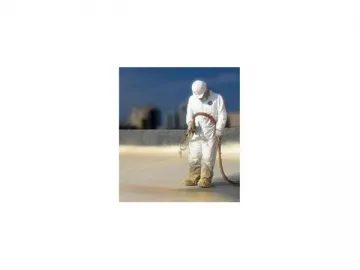

Rigid PU Spray Foam Insulation

Rigid PU Spray Foam Insulation

-

Rigid PU Foam Insulation for Refrigerator and Freezer

Rigid PU Foam Insulation for Refrigerator and Freezer

-

Push and Geared Trolley

Push and Geared Trolley