Top Entry Ball Valve

Top entry ball valve has a special construction that allows easy in-line maintenance by quick accessing to its internal parts for inspection and repairing. When any failure of the valve in pipeline occurs, the entire valve does not need to be disassembled from the pipeline, the bonnet and stem can be easily removed by removing flange screws and nuts, enabling the ball and the seats to be freely accessible and taken out.

Pressure: 600Lb

Size: NPS 8”

Material: A216-WCB

Standard connection: RF

Applications: Crude oil

Pressure: 300Lb

Size: NPS 12”

Material: A216-WCB

Standard connection: RF

Applications: Crude oil

Scan QR to Read

Links:https://www.globefindpro.com/products/8533.html

Links:https://www.globefindpro.com/products/8533.html

Recommended Products

-

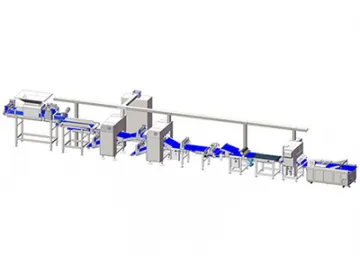

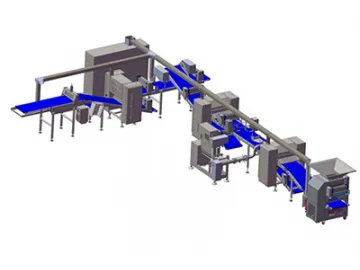

Bread

Bread

-

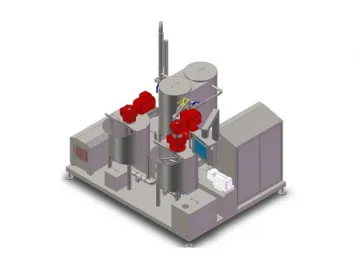

Compact Batter Mixing System for Chiffon Cake

Compact Batter Mixing System for Chiffon Cake

-

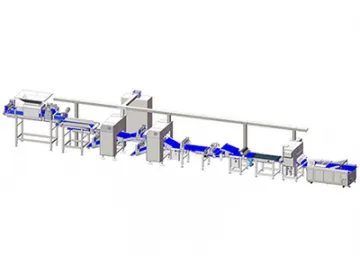

Cake

Cake

-

Die-cut Handles Block Bottom Bag Making Machine

Die-cut Handles Block Bottom Bag Making Machine

-

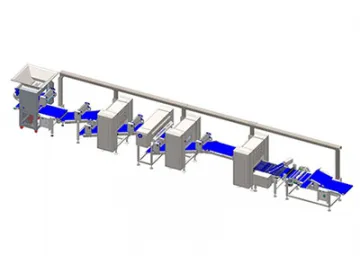

Artisan breads

Artisan breads

-

Trunnion Mounted Ball Valve

Trunnion Mounted Ball Valve

-

Control Valve, with Grinding Wheel

Control Valve, with Grinding Wheel

-

Batter Mixing System for Chiffon Cake

Batter Mixing System for Chiffon Cake

-

Flatbread

Flatbread

-

Multistage Control Valve

Multistage Control Valve

-

Pastry

Pastry

-

Water Distribution Device for Multi Oil Wells

Water Distribution Device for Multi Oil Wells