Impact Crusher

The impact crusher is commonly seen at the highway and railway construction site, where it is utilized to break down rocks. The resulting particles are generally of a standard cubical shape such as that required by highway and railway applications.

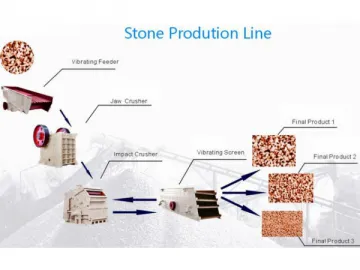

Impact crusher is often used for secondary crushing. Customers can pair this crusher with our material feeder, vibrating screen, and jaw crusher to form a complete, integrated processing line. In addition, a variety of impact crushers is available for choice according to your desired productivity.

Plenty of applications exist for this crusher, such as in hydroelectricity, highway construction, artificial aggregates, and stone production and crushing industries.

Outstanding functionality and exceptional performance partly explains why our impact crusher is so widely applied in the hydraulic engineering and residential building construction industries. Further benefits of this crusher include small footprint, simple structure, great size reduction ratio, little energy consumption, high crushing capacity, and maximum size uniformity of finished products. As one of the most promising equipment, the crusher is able to selectively crush aggregates below a given size.

Work Principle

Ores are fed into the crushing chamber via the feed hopper. The hopper contains a preliminary screening device that allows smaller ores to bypass further crushing stages, and directly exits the discharge opening. This improves crushing efficiency. The bigger particles that are left on the screen slide downward along it to enter the rotor. The dropping particles are impacted and subsequently broken by the hardened steel hammers that are fitted upon the outer edges of high-speed spinning rotor. As the broken ores fly off in the direction tangent to the circular motion of the rotor, they are thrown against a solid anvil for further fracturing. The anvil bounces the big particles back, only to collide with other particles that are being thrown towards the anvil. The space between the anvil and rotor is called the first crushing chamber, where particles are destructed repeatedly. After a few breaking cycles, middle size particles pass though the first chamber and go into the second crushing chamber for fine crushing until the desired size is reached. Finished ores are discharged from the bottom opening.

Main Features

1. This series of impact crusher costs little to operate while delivering maximum productivity. Its lightweight body is simply structured. The feed hopper comes in a large opening size. Deep crushing cavity allows extremely hard materials to be crushed.

2. Ores have natural fissures throughout their structure. As ores are thrown against the anvil, they break and fracture along these fissures, saving breaking energy and improving crushing efficiency.

3. Size reduction ration of 40:1 can be achieved during one crushing cycle. This reduces the number of crushing stages ores have to go through. Less crushing stages mean less crushing equipment needed.

4. The gap between the anvil and hammer is conveniently adjustable. Through adjustment, a proper size and shape of resulting ores can be obtained.

5. High-chromium steel is used to make the hammer, resulting in a tool that is resistant to impact and wear.

6. Parts are connected without using keyed joints. This comes with financial benefits, since it costs less to repair and inspect.

7. A most comprehensive list of features is available. Machine parts are made of highly wear-resistant materials, which lead to improved overall economic efficiency.

8. Ores are crushed in a selective manner. The product resulting from the crusher is generally of a consistent cubical shape such as that required by bridge, highway, deck, and airport construction applications.

| Model | Specification (mm) | Feed Hopper Size (mm) | Maximum Side Length of Starting Material (mm) | Productivity (t/h) | Motor Power (kw) | Machine Weight (without motor) (kg) |

| PF-0607 | φ-644×740 | 320×770 | 100 | 10-20 | 30 | 4300 |

| PF-0807 | φ-850×700 | 400×730 | 300 | 15-30 | 30-45 | 6500 |

| PF-1008 | φ-1000×800 | 400×830 | 300 | 30-60 | 37-55 | 10500 |

| PF-1010 | φ-1000×1050 | 400×1080 | 350 | 50-90 | 55-75 | 12500 |

| PF-1210 | φ-1250×1050 | 400×1080 | 350 | 70-130 | 90-110 | 15800 |

| PF-1212 | φ-1250×1250 | 400×1300 | 350 | 100-150 | 110-132 | 17500 |

| PF-1214 | φ-1250×1400 | 400×1430 | 400 | 100-180 | 132-160 | 19800 |

| PF-1315 | φ-1320×1500 | 860×1520 | 500 | 160-250 | 180-260 | 24000 |

| PF-1320 | φ-1320×2000 | 860×2030 | 500 | 300-350 | 300-375 | 29000 |

Examples of Resulting Products

Related Names

Aggregate Crushing Machine | Concrete Crusher | Gravel Crushing Equipment

Links:https://www.globefindpro.com/products/85406.html