Screw Classifier

The screw classifier is commonly used to separate coarse particles from fine powders coming out from the ball mill. After separation, fine powders advance onward into the further process. Coarse powders are returned to the ball mill for repeated grinding.

As is indicated in the above, ball mill is often followed by the screw classifier to form a complete grinding circuit. They are indispensable items in the ore dressing process.

Highly wear resistant material is used to make the consumable parts of our spiral classifier, which ensures their long service life. In addition, the machine provides large material handling capacity.

Functions

1. The spiral classifier is important equipment in gravity dressing of minerals, where different minerals are separated and sorted. With this equipment, sand can be distinguished from mine mud and categorized into several grades. This classifier is also suitable for the desliming and de-watering operations which can be experienced in mineral washing process.

2. Simple structure, dependable operating efficiency, and convenient operation are the major benefits of the machine for user companies.

3. Basic concept behind the classifier for gravity is that particles with different densities have different velocities of motion in water under the influence of gravity. Finer particles tend to flow on the surface while coarse ores sink to the bottom. As a result, finer powders naturally overflow the trough of the classifier. After that, the bottom ores are pulled to the surface by the rotating screw and discharged from the tough, too.

Work Principle

The spiral classifier takes advantage of density differences of ores to be separated. Under the influence of gravity, lighter impurities float on the surface of water-filled trough and subsequently are removed from the classifier. As the screw rotates, water contained in the trough is pushed forward and ores with heavy weight go down to the bottom.

Structure

The spiral classifier is comprised of trough, gear reducer, motor, central shaft, spiral screw, and various supporting parts.

Please note

XBM Company is well-known for its screw classifiers. Decades of experience gives XBM Company the expertise needed to provide customers with quality spiral classifiers that made from stick welding steel plate. We are a qualified supplier of XBM spiral classifier. Almost all our crushing equipment can be paired with this classifier.

Benefits

1. High throughput, low energy consumption and high ore sorting efficiency.

2. High sorting accuracy

3. Optimal structural design is suitable for various fine powder sorting applications.

4. The classifier is highly automated.

| Model | Spiral Screw Diameter (mm) | Trough Length (mm) | Screw Rotation Speed (r/min) | Production Capacity (t/d) | Motor Power(kw ) | Machine Weight (t) | ||

| Back to Sand | Overflow | For Driving | For Lifting | |||||

| FG7.5 | 750 | 5500 | 6-10 | 340-570 | 65 | 3.0 | HM | 2.7 |

| FG10 | 1000 | 6500 | 5.0-8.0 | 675-1080 | 110 | 5.5 | HM | 4.43 |

| FG12 | 1200 | 6500 | 5.0-8.0 | 1170-1870 | 155 | 5.5 | 1.5 | 8.7 |

| FG15 | 1500 | 8400 | 4.0-6.0 | 1830-2740 | 235 | 7.5 | 2.2 | 12.5 |

| FG20 | 2000 | 8400 | 4.0-6.0 | 3240-5400 | 400 | 11 | 2.8 | 20.5 |

| FG24 | 2400 | 9210 | 3.6 | 4650-7450 | 580 | 15 | 3.0 | 25.6 |

| FG30 | 3000 | 1250 | 3.2 | 11625 | 890 | 22 | 4.0 | 37.7 |

| 2FG12 | 1200 | 6500 | 5.0-8.0 | 2340-3740 | 310 | 5.5 × 2 | 1.5 × 2 | 14.0 |

| 2FG15 | 1500 | 8400 | 4-6.0 | 3660-5480 | 470 | 7.5 × 2 | 1.5 × 2 | 21.1 |

| 2FG20 | 2000 | 8400 | 3.0-5.5 | 7780-11800 | 800 | 11 × 2 | 2.8 × 2 | 36.5 |

| 2FG24 | 2400 | 9210 | 3.6 | 13600 | 1160 | 15 × 2 | 3 × 2 | 46.8 |

| 2FG30 | 3000 | 12500 | 2.0-3.2 | 14600-23400 | 1785 | 22 × 2 | 4 × 2 | 73.0 |

Related Names

Spiral Sand Classifier | Screw Grit Classifier | Spiral Ore Concentrator

Links:https://www.globefindpro.com/products/85411.html

-

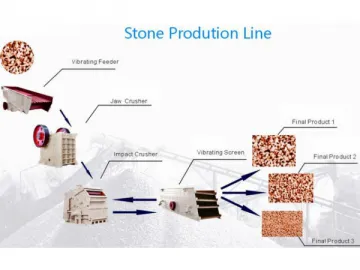

Sand and Gravel Production Line

Sand and Gravel Production Line

-

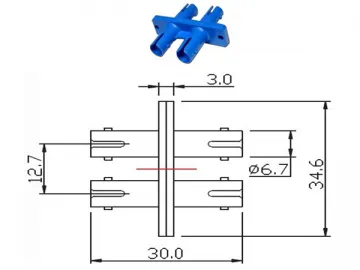

MPO Fiber Optic Cassette

MPO Fiber Optic Cassette

-

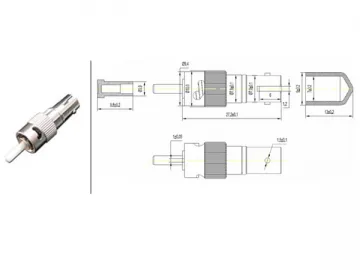

Plug-in Type Fixed Attenuator

Plug-in Type Fixed Attenuator

-

Cement Production Line

Cement Production Line

-

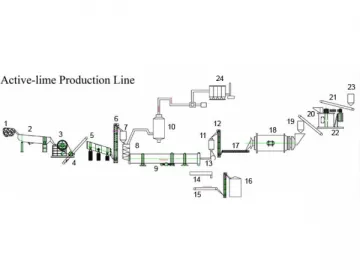

Active-lime Plant/Quicklime Plant

Active-lime Plant/Quicklime Plant

-

SC/LC/FC/ST/MU/D4/DIN Fiber Optic Adapter

SC/LC/FC/ST/MU/D4/DIN Fiber Optic Adapter

-

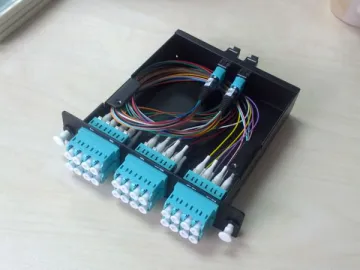

Fixed Type Optical Distribution Frame

Fixed Type Optical Distribution Frame

-

3 Channel WDM

3 Channel WDM

-

Concrete H Beam Machine

Concrete H Beam Machine

-

Ball Mill

Ball Mill

-

Impact Crusher

Impact Crusher

-

Spiral Separator

Spiral Separator