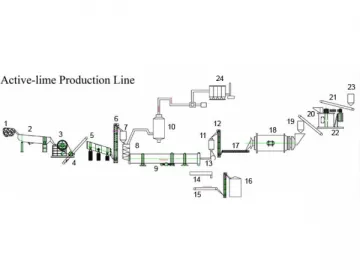

Sand and Gravel Production Line

A complete sand and gravel production line is primarily comprised of jaw crusher, hammer crusher, cone crusher, impact crusher, vibrating screen, dewatering bucket wheel, and belt conveyor. It is commonly seen at the building, road, bridge, and railway construction sites, providing users with reliability, ease of operation, efficiency, and optimized structure.

Main Features

1. The highly automated sand and gravel production line generally has high production capacity. The resulting product is generally of a consistent cubical shape, with no internal cracks, thus being able to withstand high compressive force.

2. Equipment on the production line requires limited maintenance and repair. Highly wear-resistant materials are used to make the consumable parts, resulting in extended usage life. This saves significant amount money that otherwise would be spent on parts replacement.

3. This new line of comminution equipment is designed to crush and grind limestone, greystone, granite, and cobble stone. Finished product quality totally meets the GB14685-2001 standard. Our comminution line has provided quality aggregates to the highway, railway, and reservoir construction industries as well as concrete mixing plant.

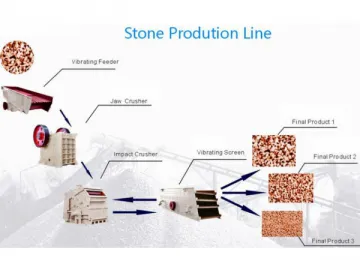

General Production Flow

Hopper---Feeder---Jaw Crusher---Impact Crusher---Vibrating Screen---Finished Product

Please note

A conveyor can be used to transfer materials between equipment.

Process

To start off, stone materials are evenly fed into the jaw crusher for primary crushing. The resulting stones are conveyed via the belt conveyor to the impact crusher, where they are break down into smaller pieces. Fine-sized particles are passed through the vibrating screen for separation according to their size. Coarse-sized particles are returned to the impact crusher for repeated crushing. Finally, finished products of required size are transported to a sand pile via the belt conveyor. To protect the working environment, ancillary dust collector can be used to remove any dust during the process.

Performance

1. Except for the day-to-day turn-on, turn-off, and maintenance operation, the whole comminution process almost does not require any manual handling tasks. Low operation cost, maximum throughput yield, and high quality standard of finished product are the major benefits of the production line for its end users.

Custom Design

The sand and gravel manufacturing line can be re-configured depending on the size and usage of the finished product as well as customer desired handling capacity.

Extra Services

Over the years, we have been delivering comprehensive services to customers prior to, during and after the purchase. We offer to work out a site layout plan for customers and install their production line on the proposed site according to the design plan. Varied equipment on this line will be properly arranged according to the site conditions, with an aim to achieve maximum economics.

Sand Crushing Plant/Stone and Sand Production Line

| Serial Number | Max. Feed Size (mm) | Crushing Capacity (t/h) | Models, specifications and quantities | |||||

| Feeding Equipment | Coarse Crushing Equipment | Fine Crushing Equipment | Classifying and Screening Equipment | Belt Conveyor (m) | Installed Power (kw) | |||

| 1 | 300 | 30 | GZD6018(3kw) | PEF400 × 600(30kw) | PF1007(45kw) | 3YZ1236 (15kw) | 60-90(20kw) | 120 |

| 2 | 340 | 50 | GZD6018(3kw) | PEF400 × 600(30kw) | PF1007(45kw) | 3YZ1545(22kw) | 100-130(30kw) | 140 |

| 3 | 400 | 80 | GZD8030(5kw) | PEF500 × 750(55kw) | PF1010(75kw) | 3YZ1548(22kw) | 130-160(30kw) | 200 |

| 4 | 480 | 100 | GZD9638(5kw) | PEF600 × 900(75kw) | PF1210(130kw) | 3YZ1548(22kw) | 140-180(40kw) | 280 |

| 5 | 560 | 150 | GZD1142(10kw) | PEF750 × 1060(90kw) | PF1210(130kw) | 3YZ1845(22kw) | 200-240(50kw) | 300 |

| 6 | 630 | 200 | GZD1149(13kw) | PEF900 × 1060(110kw) | PF1212(140kw) | 3YZ2050(30kw) | 200(40kw) | 350 |

| 7 | 630 | 250 | GZD1149(13kw) | PEF900 × 1060(110kw) | PF1214(180kw) | 3YZ2050(30kw) | 200(40kw) | 400 |

| 8 | 650 | 300 | GZD1352(15kw) | PEF900 × 1200(110kw) | PF1214(180kw) | 3YZ2160(30kw) | 250(50kw) | 450 |

| 9 | 650 | 350 | GZD1352(15kw) | PEF900 × 1200(132kw) | PF1315(250kw) | 3YZ2160(30kw) | 250(50kw) | 500 |

| 10 | 650 | 450 | GZD1352(15kw) | PEF900 × 1200(132kw) | PF1214/2(300kw) | 3YZ2145/2(60kw) | 350(60kw) | 600 |

Related Names

Stone Crushing Equipment | Construction Aggregate Making Equipment | Building Materials Manufacturing Equipment

Links:https://www.globefindpro.com/products/85412.html