Mineral Processing Line

On the mineral processing line, minerals are crushed and separated according to their size. Varied mineral processing equipment is available according to the specific types of material to be processed. Black metal, non-ferrous metal, and tritomites are a just few materials that can be sized by this processing line. Different separation techniques can be used, such as magnetic separation, gravity concentration, forth flotation, and electrostatic separation.

We have launched several lines of mineral processing equipment to process iron ore, copper ore, lead-zinc ore, gold-silver ore, and fluorite ore.

Magnetic Separation

The magnetic separation line is comprised of the jaw crusher, ball mill, classifier, magnetic separator, flotation equipment, dewatering equipment, drier, feeder, and conveyor.

Benefits

High efficiency, low energy cost, high production capacity, cost efficiency.

Process

Mineral ores are first sent to the jaw crusher for primary crushing. Crushed ores of desired size are conveyed to the ball mill for grinding. The resulting mineral powder advances onward into the further process, where minerals are classified according to their size by exploiting the differences in their specific gravity. Clean, separated ore mixture arrives at the magnetic separator. Magnetically susceptible minerals are separated from the mixture under the magnetic force. In the flotation equipment, special chemicals are added to the floatation reagent to separate the desired minerals from the mixture. After flotation, ores might contain a lot of water within themselves. That is why the dewatering equipment is needed to remove excess water from the ore. Finally, the dewatered ore is dried by the drier and subsequently discharged from the mineral processing line.

0. Raw Ore; 1. Vibrating Feeder; 2. PE Series Jaw Crusher; 3. PEX Series Jaw Crusher; 4. Vibrating Scree;n 5. Dry Type Roller Cleaner; 6. Hopper; 7. Pendulum Feeder; 7A. Electromagnetic Vibrating Feeder; 8. Ball Mill; 9. Spiral Separator; 9A. High Frequency Screen; 10. Magnetic Separator (Gentle Washing ); 11. Magnetic Separator (Intensive Washing); 12. Magnetic Separator (Sweeping and Cleaning); 13. Wet Fine Ore; 14. Ore Concentration Device; 15. Filter Press; 15A. Filter; 16. Dryer; 17. Dry Fine Powder; 18. Tailings

Related Names

Mineral Beneficiation Equipment | Ore Processing Machine | Iron and Copper Remover

Links:https://www.globefindpro.com/products/85423.html

-

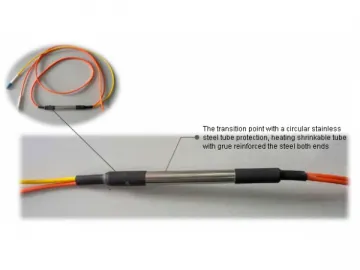

Mode Conditioning Patch Cable

Mode Conditioning Patch Cable

-

Rack-mounted Type Optical Distribution Frame

Rack-mounted Type Optical Distribution Frame

-

100M Card Type Fiber Media Converter

100M Card Type Fiber Media Converter

-

Multi-Cyclone Separator

Multi-Cyclone Separator

-

CWDM

CWDM

-

MT-RJ/MPO Fiber Optic Patch Cord

MT-RJ/MPO Fiber Optic Patch Cord

-

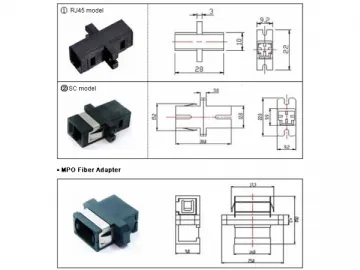

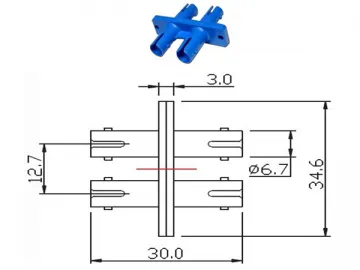

MT-RJ/MPO Fiber Optic Adapter

MT-RJ/MPO Fiber Optic Adapter

-

Optical Time Domain Reflectometer

Optical Time Domain Reflectometer

-

SC/LC/FC/ST/MU/D4/DIN Fiber Optic Patch Cord

SC/LC/FC/ST/MU/D4/DIN Fiber Optic Patch Cord

-

Pulse Jet Dust Collector

Pulse Jet Dust Collector

-

SC/LC/FC/ST/MU/D4/DIN Fiber Optic Adapter

SC/LC/FC/ST/MU/D4/DIN Fiber Optic Adapter

-

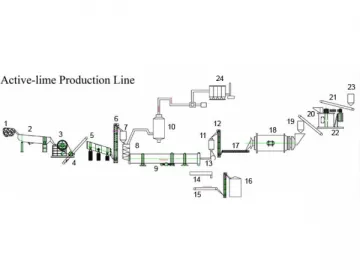

Active-lime Plant/Quicklime Plant

Active-lime Plant/Quicklime Plant