Ceramsite Sand Production Line

In a ceramsite sand production line, raw feed is processed into a tiny, solid ball shape with ultra-smooth surface, via crushing, screening, calcining, and cooling processes. According to the variety of material to be crushed, different configurations may be used. The equipment is ideally suitable for processing clay, gangue, pulverized coal, shale, and urban sewage sludge.

Process Flow

1. Silo ; 2. Conveyor ; 3. Rotary Dier ; 4. Air-Flow Dust Remover; 5. Conveyor ; 6. Conveyor ; 7. Dic Feeder ; 8. Dust Remover ; 9. Rotary Kiln ; 10. Elevator ; 11. Silo ; 12. Ball Mill ; 13. Elevator ; 14. Rotary Cooler ; 15. Burner (Gas /Oil)

1.Ceramsite Production Equipment

I. Uniform granule size

II. High size reduction ratio

III. Reliable operation

IV. Sturdy construction with extended use life

2. Usage

The ceramsite sand production line is primarily designed to produce ceramic particles, or ceramsite sand as some might call it. Light weight, low density, maximum air permeability, low breakage rate, maximum softening coefficient and exceptional frost resistance are common characteristics of ceramsite sand.

Due to its desired properties, ceramsite sand is widely used in building materials, gardening, refractory, chemical, and oil industries. Advancement in processing technology allows ceramsite sand to become more widespread than ever.

3. Process

I. Plasticizing

The plasticizing process can be applied to clay and clayey material.

Process Flow

Clay--plasticizing, surface smoothing by roller, granulating-roasting-cooling-finished product

II. Mud-into-Ball

This processing technique is suitable for fly ash as well as powdery material

Process Flow

Fly ash-mixing, surface smoothing-granulating-roasting-cooling-finished product

III. Powder-into-Ball

In powder-into-ball practice, shale or gangue is sent through drying, grinding, pre-wetting, granulating, roasting, and cooling. Special additives may be needed for this process.

IV. Breaking

This method is mainly suitable for shale.

Process Flow

Raw feed-breaking, sizing-roasting-cooling-finished product

Fuels

According to local fuel supply condition, bituminous coal, crude oil or natural gas can be used

3. Equipment on Ceramsite Sand Production Line

Major equipment used in production of ceramsite sands includes crusher, screen, belt conveyor, feeder, discharge machine, raw material storage warehouse, dust-fall room, induced draft fan, kiln, coal injection system, and control cabinet. Stepless motor is used to control the material feeding speed, rotation speed of kiln, and more.

Related Names

Ceramic Pellet Manufacturing Machine | Mineral Crushing and Screening Equipment | Ceramsite Sand Making Machine

Links:https://www.globefindpro.com/products/85438.html

-

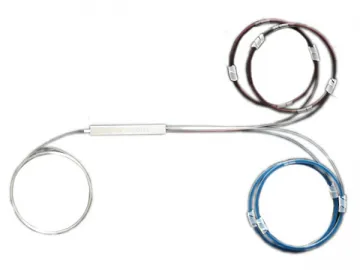

PLC Splitter

PLC Splitter

-

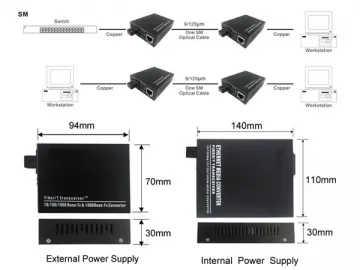

1000M Card Type Fiber Media Converter

1000M Card Type Fiber Media Converter

-

SMA Fiber Optic Patch Cord

SMA Fiber Optic Patch Cord

-

Four-Axle Cantilever Suspension

Four-Axle Cantilever Suspension

-

German Type Inboard Drum Axle Series

German Type Inboard Drum Axle Series

-

100M Dual Fiber Media Converter

100M Dual Fiber Media Converter

-

Armored Fiber Optic Patch Cord

Armored Fiber Optic Patch Cord

-

1000M Single Fiber Media Converter

1000M Single Fiber Media Converter

-

Aerated Concrete Block Production Line

Aerated Concrete Block Production Line

-

Pull-out Type Optical Distribution Frame

Pull-out Type Optical Distribution Frame

-

Loopback Adapter

Loopback Adapter

-

MT-RJ/MPO Fiber Optic Patch Cord

MT-RJ/MPO Fiber Optic Patch Cord